Nissan Pathfinder: Removal and Installation - Oil Pan ++

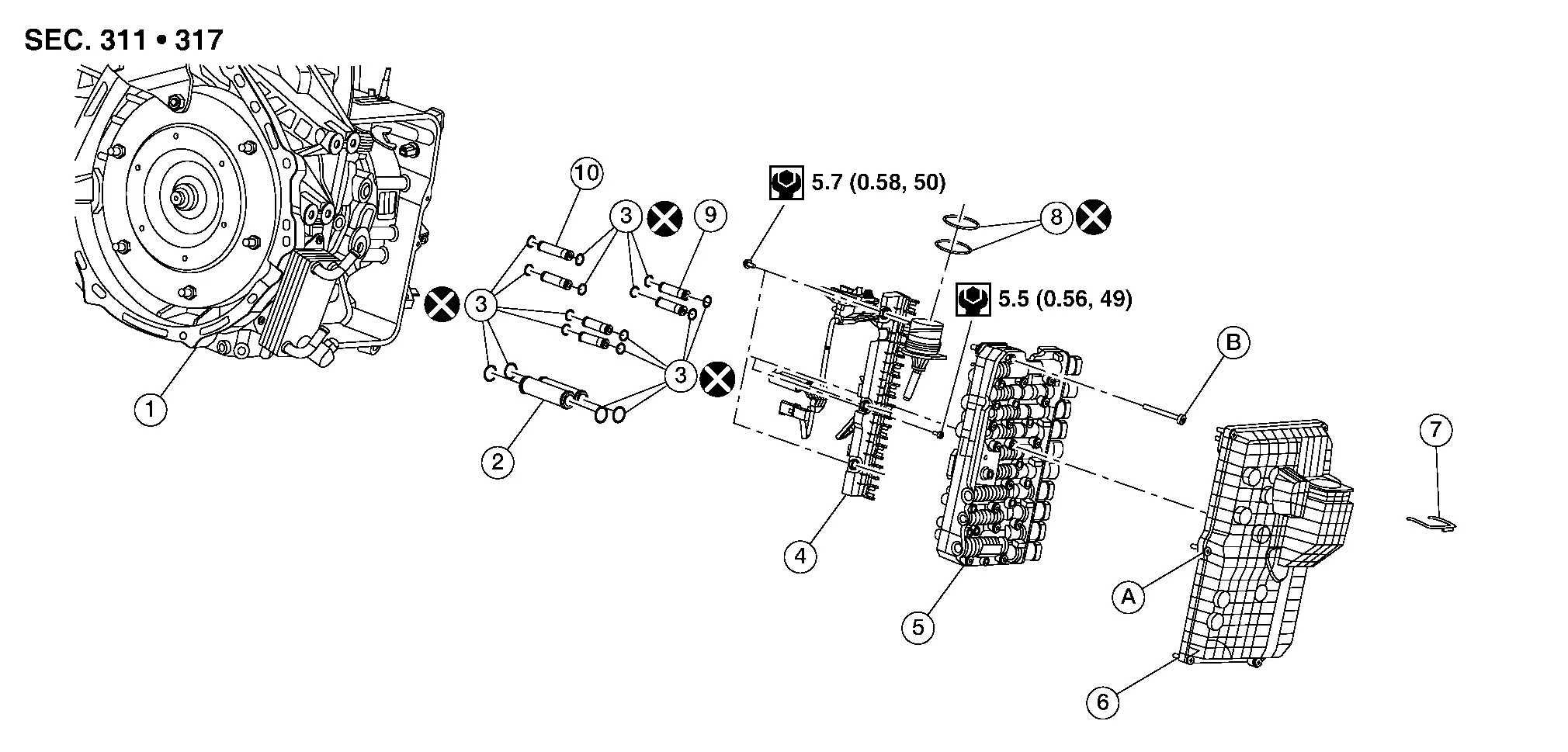

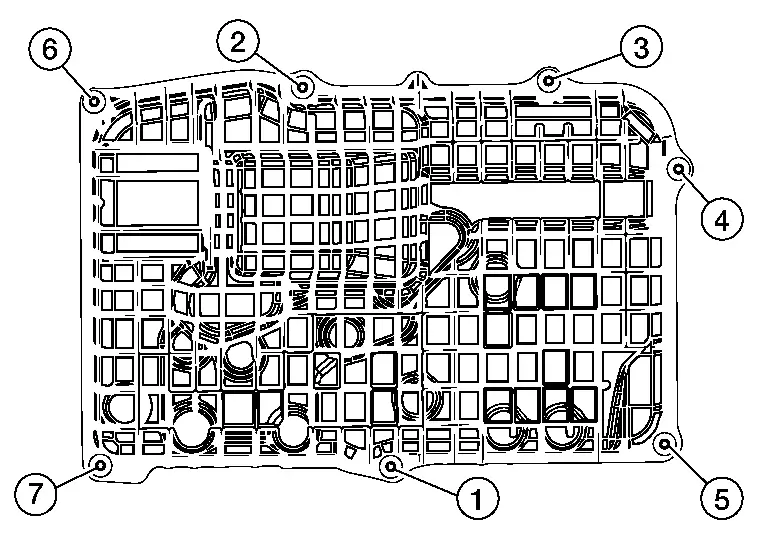

Exploded View

| 1. | Transaxle assembly | 2. | Connector tube | 3. | O-ring |

| 4. | Sensor assembly | 5. | Control valve | 6. | Oil pan |

| 7. | Clamp | 8. | O-ring | 9. | Adapter |

| 10. | Adapter | A. | Refer to Removal and Installation. | B. | Refer to Removal and Installation. |

Removal and Installation

WARNING:

-

Situate the vehicle on a flat and solid surface.

-

Place chocks at front and back of rear wheels.

-

For engines not equipped with engine slingers, attach proper slingers and bolts described in PARTS CATALOG.

CAUTION:

-

Always work safely.

-

Do not start work until the engine and exhaust system are cooled completely.

-

Refer to the applicable sections for warnings, cautions, notes, and instructions if necessary procedures are not included in the engine section.

-

For supporting, lifting and jacking points, refer to Garage Jack and Safety Stand and 2–Pole Lift.

-

Always use the support point specified for lifting.

-

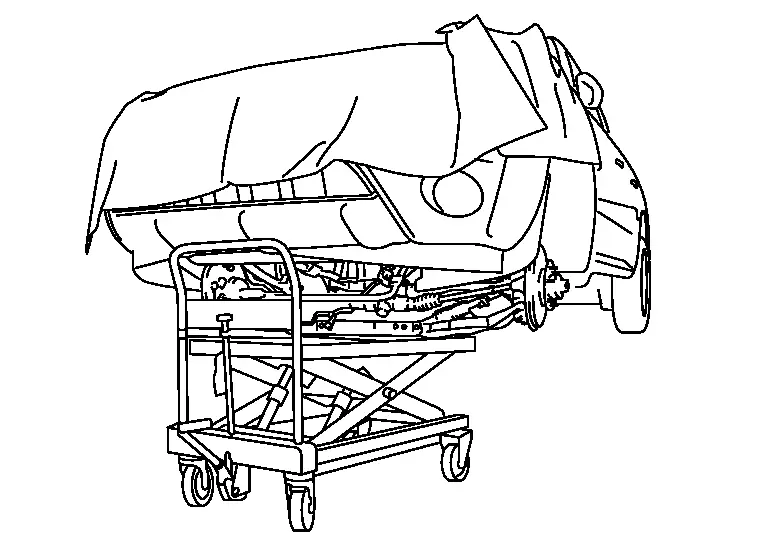

Support the Nissan Pathfinder vehicle at the rear axle jacking point with transmission jack or similar tool before removing the engine in preparation for the backward shift of the center of gravity.

-

When replacing transaxle assembly, perform "ADDITIONAL SERVICE WHEN REPLACING TRANSAXLE ASSEMBLY". Refer to Description.

NOTE:

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

| Never Reuse These Parts | Part # Prefix | For additional information: |

|---|---|---|

| Hose clamp | 31088F | WATER HOSE EXPLODED VIEW |

| O-ring | — | CONTROL VALVE EXPLODED VIEW |

| Wheel hub lock nut | 40262 | FRONT WHEEL HUB EXPLODED VIEW |

| Nut | 40040B | FRONT WHEEL HUB EXPLODED VIEW |

| O-ring | 92471 | COOLER PIPE AND HOSE EXPLODED VIEW |

| Gasket | 20691 | EXHAUST SYSTEM EXPLODED VIEW |

| Seal bearing | 20695 | EXHAUST SYSTEM EXPLODED VIEW |

| Bolt | 20020B | EXHAUST SYSTEM EXPLODED VIEW |

| Nut | 20020A | EXHAUST SYSTEM EXPLODED VIEW |

| Bolt | 37010AA | REAR PROPELLER SHAFT EXPLODED VIEW |

| Nut | 37050B | REAR PROPELLER SHAFT EXPLODED VIEW |

| Nut | 54040B | FRONT COIL SPRING AND STRUT EXPLODED VIEW |

| Nut | 54060B | FRONT STABILIZER EXPLODED VIEW |

Release fuel pressure. Refer to Work Procedure.

Drain engine coolant. Refer to Draining.

CAUTION:

-

Perform this step when the engine is cold.

-

Do not allow the engine coolant to contact the drive belts.

Recycle the refrigerant. Refer to Recycle Refrigerant.

Remove the cowl top and cowl top extension. Refer to Removal and Installation.

Remove the core support cover. Refer to Exploded View.

Remove the front air duct. Refer to Exploded View.

Remove the battery and battery tray. Refer to Removal and Installation.

Disconnect the harness connectors from the ECM. Refer to Harness Connector (LEVER LOCKING TYPE).

Remove the ECM and ECM bracket. Refer to Exploded View.

Remove the front wheels and tires using power tool. Refer to Removal and Installation.

Remove the fender protector side cover (RH/LH). Refer to Exploded View.

Partially remove the front over fender (RH/LH). Refer to Exploded View.

Partially remove the front fender protector (RH/LH). Refer to Exploded View.

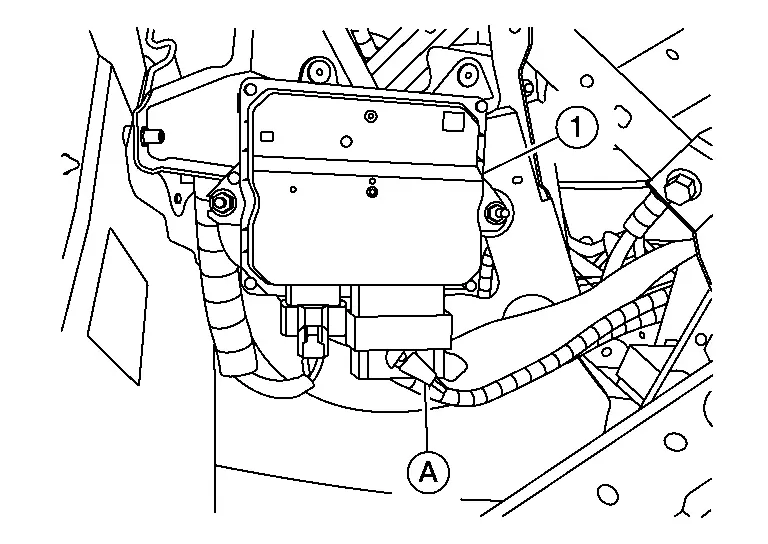

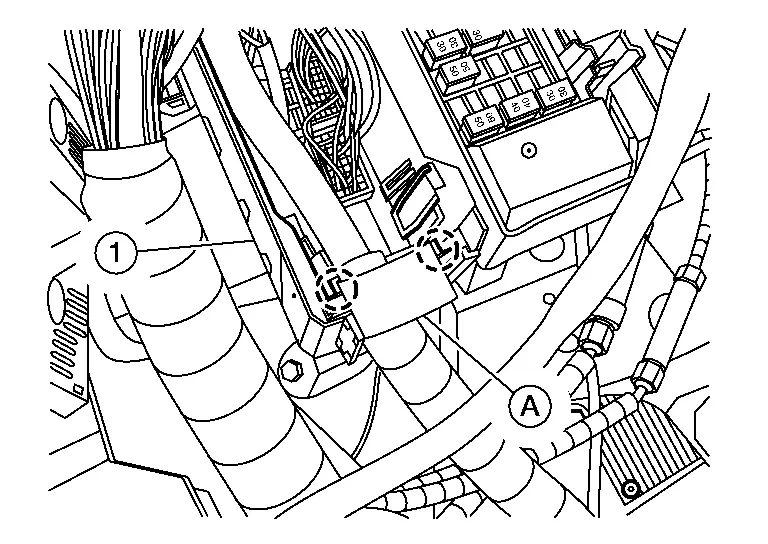

Disconnect the harness connector (A) from the electric intake valve timing control module (1).

Release harness retainer and reposition engine harness into engine room.

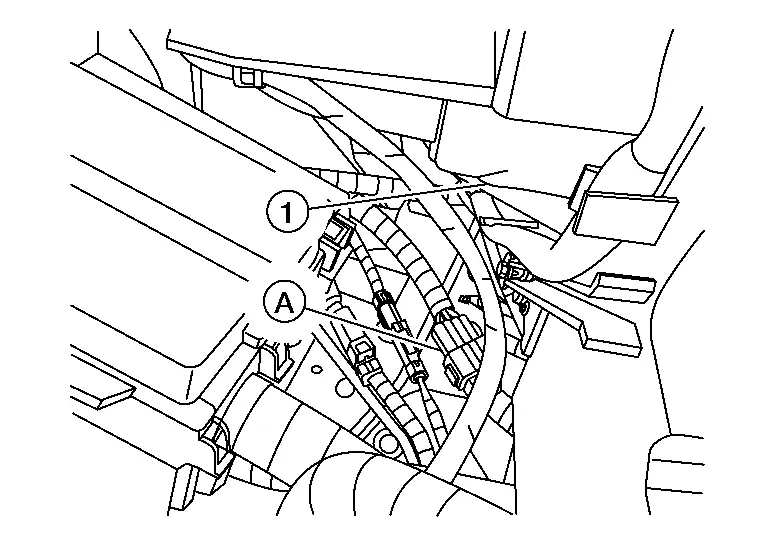

Disconnect harness connector (A).

| (1) | : Front combination lamp (LH) |

Remove the fuse block cover.

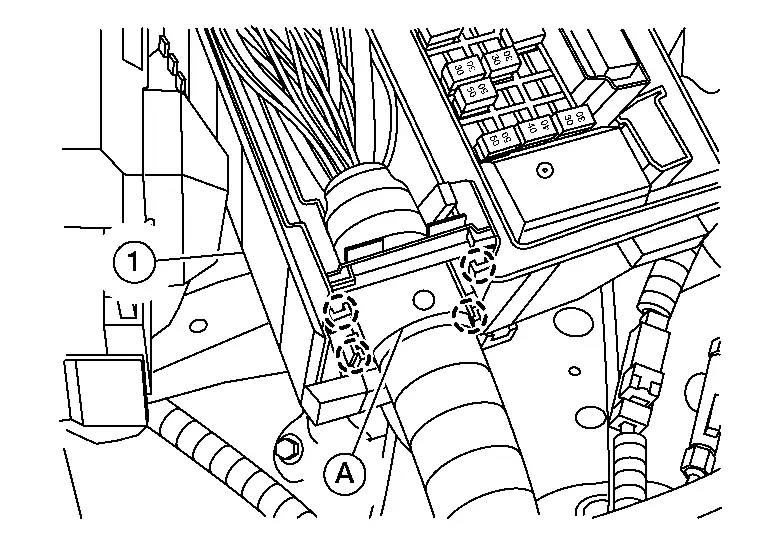

Release fuse block cover A (A) pawls from the fuse block (1) and remove the fuse block cover A.

|

: Pawl |

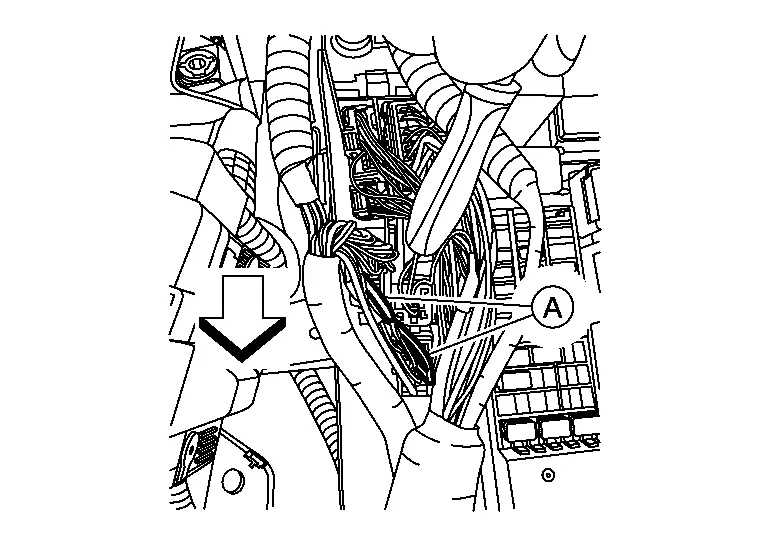

Reposition engine harness.

Release fuse block cover B (A) pawls from the fuse block (1) and remove the fuse block cover B.

|

: Pawl |

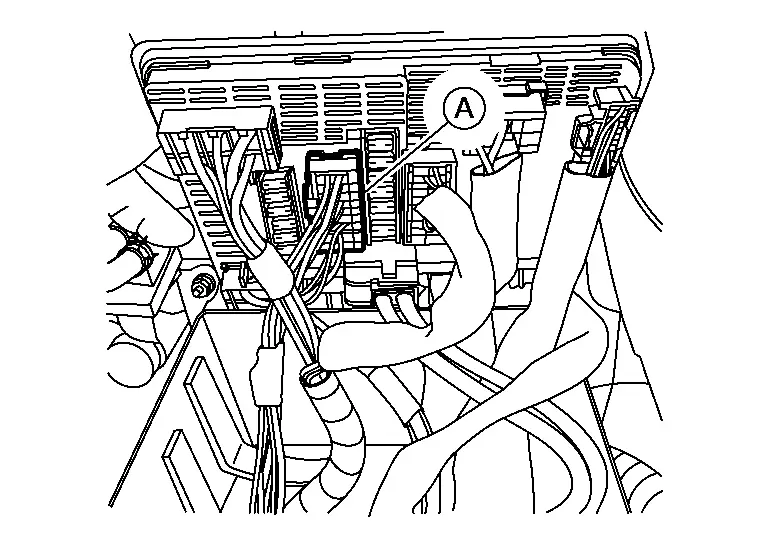

Disconnect the harness connectors (A) from the fuse block.

|

: Front |

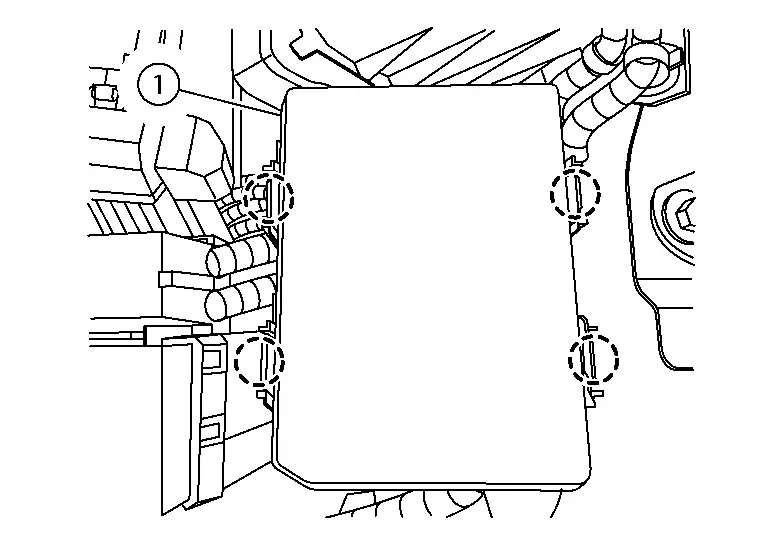

Release the pawls and separate the IPDM E/R (1) from the IPDM E/R case.

|

: Pawl |

Release pawls and remove the IPDM E/R cover (A) from the IPDM E/R housing.

|

: Pawl |

Disconnect the harness connector (A) from the IPDM E/R.

Remove bolt (A) and nut (B) and reposition engine harness.

Remove the radiator hose (upper) from the water outlet pipe. Refer to Exploded View.

Remove the fuel line protector and disconnect the fuel feed using suitable tool. Refer to Exploded View.

Remove the EVAP hose from the vacuum delay valve. Refer to Exploded View.

Remove the vacuum hose from the intake manifold. Refer to Exploded View.

Remove the high-pressure flexible hose from the high-pressure pipe. Refer to Exploded View.

Remove the low-pressure flexible hose from the low-pressure pipe. Refer to Exploded View.

Remove the battery positive terminal cover from the fusible link box (battery). Refer to Exploded View.

Remove the positive cable nut and remove the positive cable from the fusible link box (battery). Refer to Exploded View.

Remove the heater hoses from the water outlet and heater pipe. Refer to Exploded View.

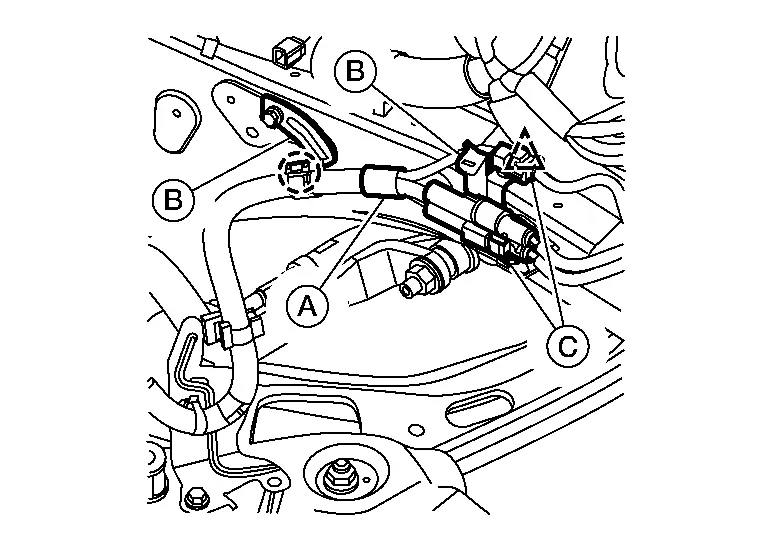

Disconnect the harness connectors (C) for the steering gear and linkage assembly harness (A) and remove the harness from brackets (B).

|

: Clip |

|

: Pawl |

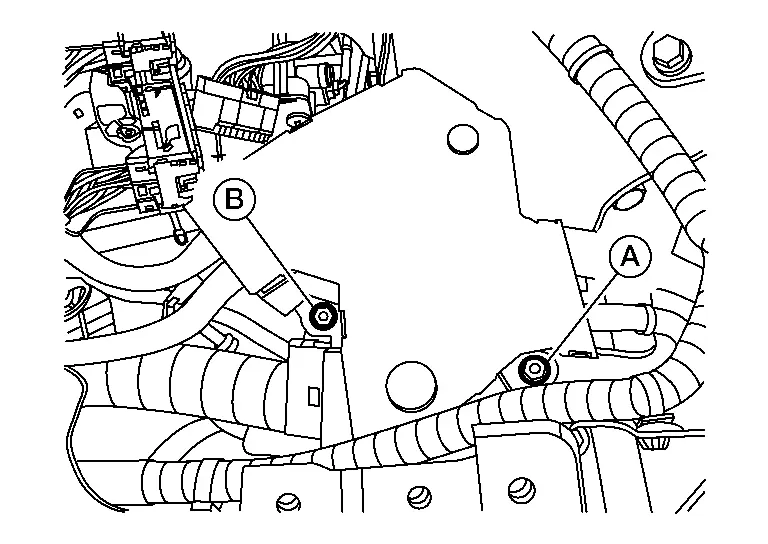

Remove bolt (A) and remove the ground cable from the front cover and release harness retainer (B) from bracket.

| (1) | : Valve timing control cover (bank 2) |

Remove the engine mounting insulator (RH).

Remove the ground cable from the transaxle assembly.

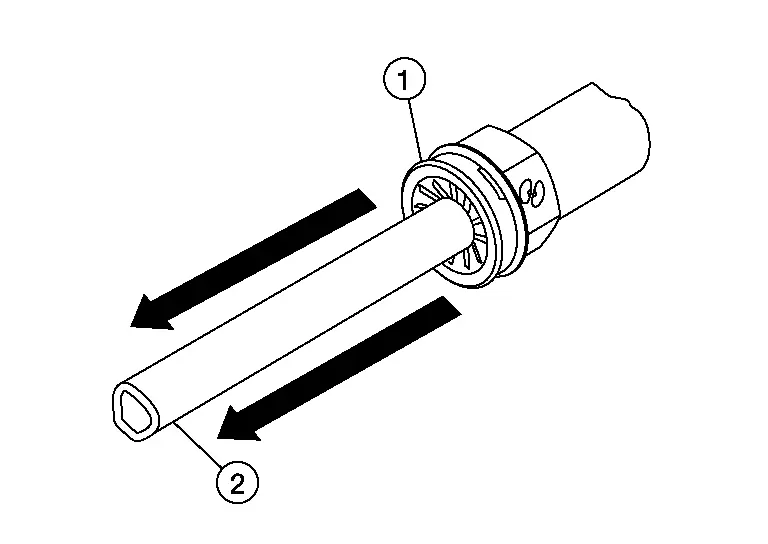

Remove the A/T fluid cooler hoses from the A/T fluid warmer using the following procedure:Remove the A/T fluid cooler hose cap (1) from the A/T fluid cooler hose (2).

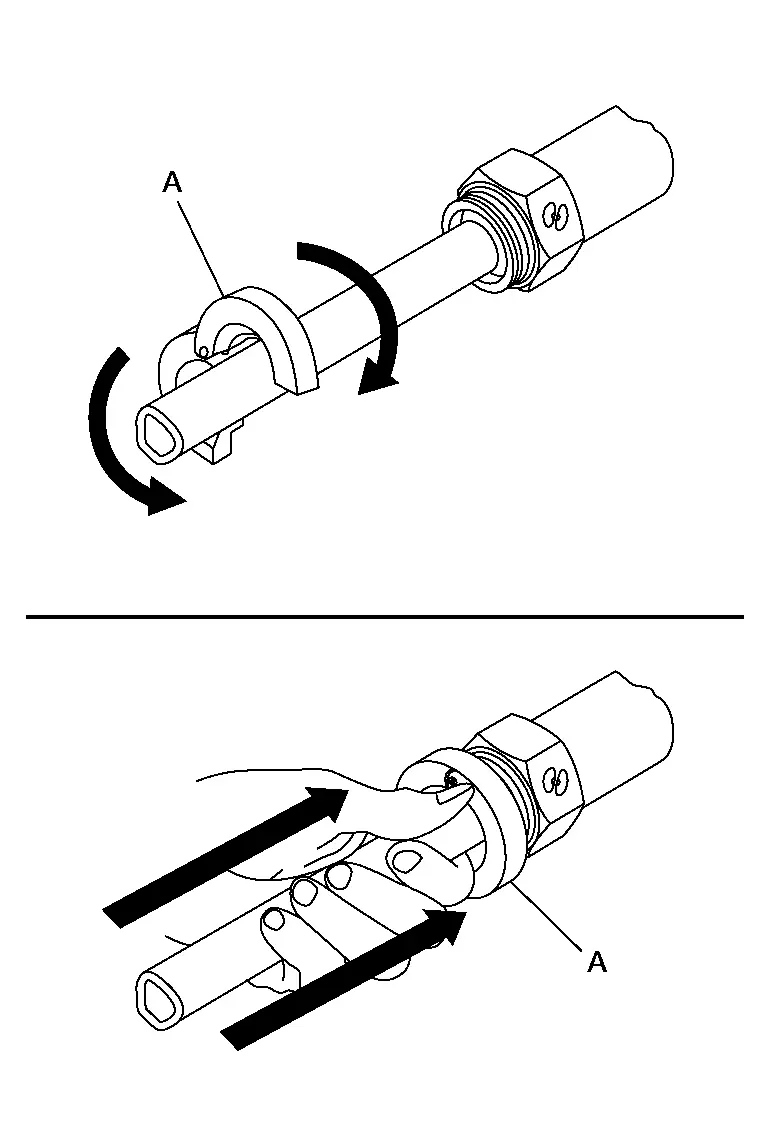

Install suitable tool (A) on to the A/T fluid cooler hose at the A/T fluid warmer.

Rotate suitable tool counterclockwise 60 degrees to release snap ring.

Remove A/T fluid cooler hose (1) from the A/T fluid warmer.

| (A) | : Suitable tool |

Remove the front exhaust tube. Refer to Exploded View.

Remove the propeller shaft assembly. Refer to Removal and Installation (4WD models only).

Remove steering pinch bolt and separate the lower joint from steering gear and linkage. Refer to Exploded View.

CAUTION:

With the steering linkage disconnected, the spiral cable may snap by turning the steering wheel beyond the limited number of turns. Secure the steering wheel during removal of the steering gear.

Remove the front disc brake rotor (RH/LH). Refer to Removal and Installation.

Remove wheel sensor bolt and position wheel sensor aside. Refer to Exploded View.

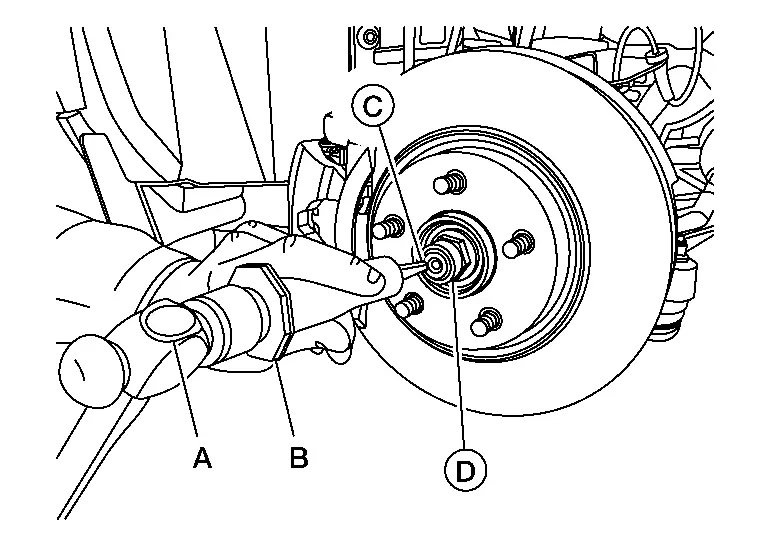

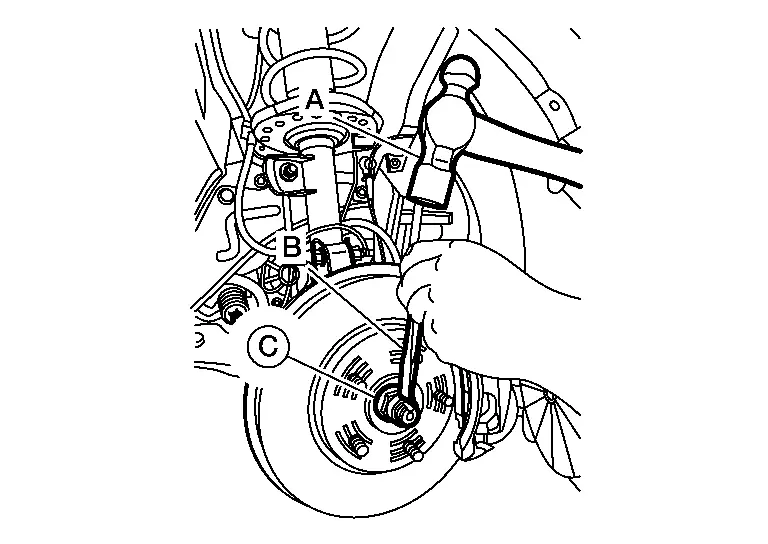

Using suitable tool (A) and Tool (B) release staked area (C) of wheel hub lock nut (D).

| Tool (B) | : — (NI-52982) |

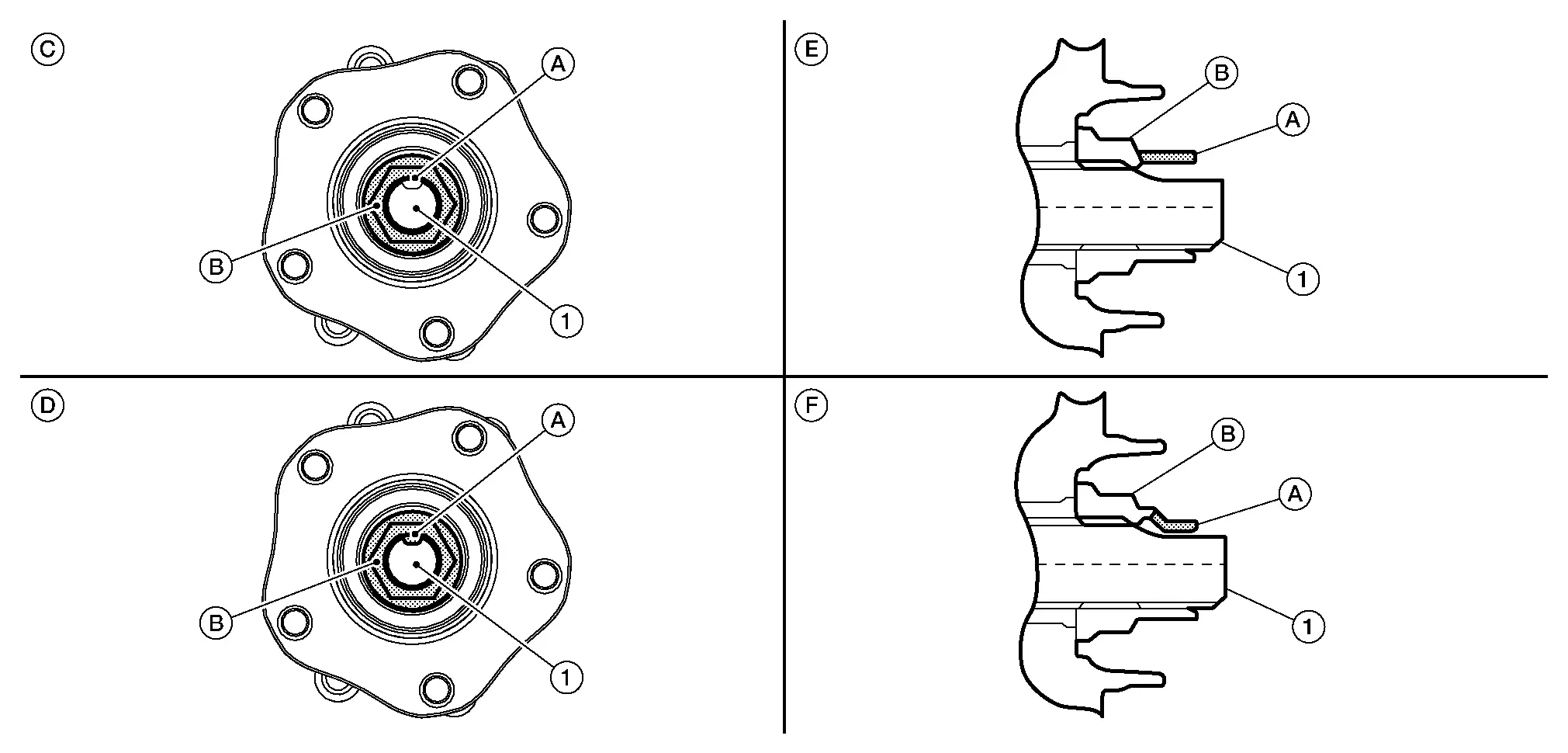

Visually verify that staked area (A) of wheel hub lock nut (B) is completely released from front drive shaft (1) or damage to drive shaft can occur.

WARNING:

To avoid risk of death or severe personal injury:

Be sure that staked area of wheel hub lock nut is fully released or damage to drive shaft can occur. Do not damage front drive shaft threads.

| (C) | : Fully released |

| (D) | : Not fully released |

| (E) | : Fully released (sectional view) |

| (F) | : Not fully released (sectional view) |

Loosen wheel hub lock nut but do not remove from drive shaft.

WARNING:

To avoid risk of death or severe personal injury:

Do not use power tool. Do not reuse wheel hub lock nut. When loosening wheel hub lock nut, if it does not turn smoothly, verify staked area is completely released. Do not damage front drive shaft threads.

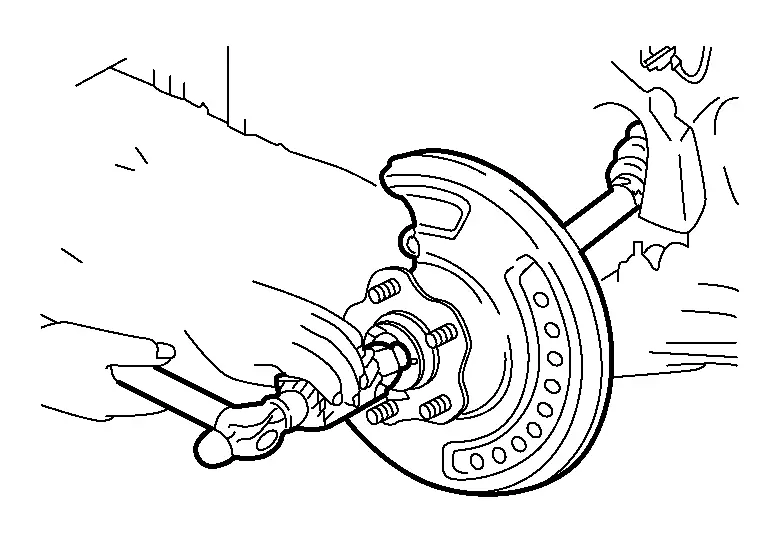

Using a piece of wood and a suitable tool, tap on the wheel hub lock nut to disengage drive shaft from wheel hub.

WARNING:

To avoid risk of death or severe personal injury:

Do not place drive shaft at an extreme angle. Be careful not to over extend slide joint. Do not allow drive shaft to hang without support.

NOTE:

NOTE:

Use a suitable puller if drive shaft cannot be separated from wheel hub and bearing.

Remove wheel hub lock nut.

CAUTION:

Do not reuse wheel hub lock nut.

Remove nuts and bolts and separate the steering knuckle from the strut. Refer to Exploded View.

CAUTION:

Do not reuse nuts.

Remove nuts and separate the stabilizer connecting rod from the strut. Refer to Exploded View.

Remove the bearing retainer bolts and remove the bearing retainer. Refer to Exploded View.

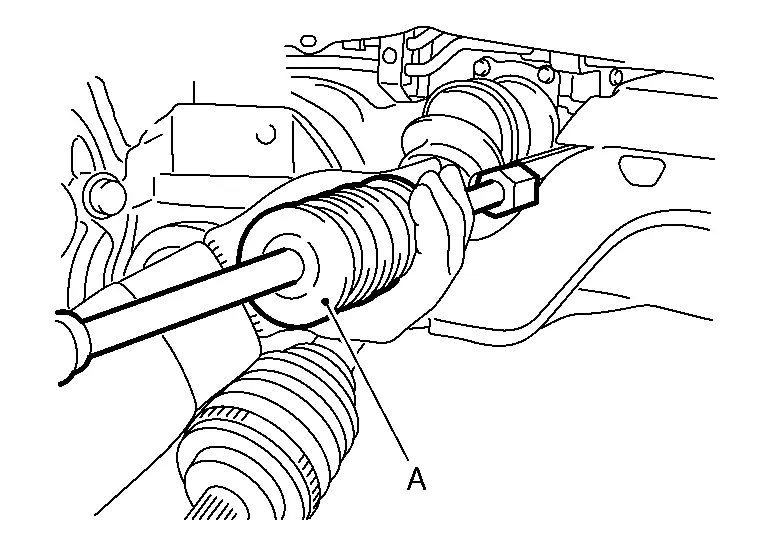

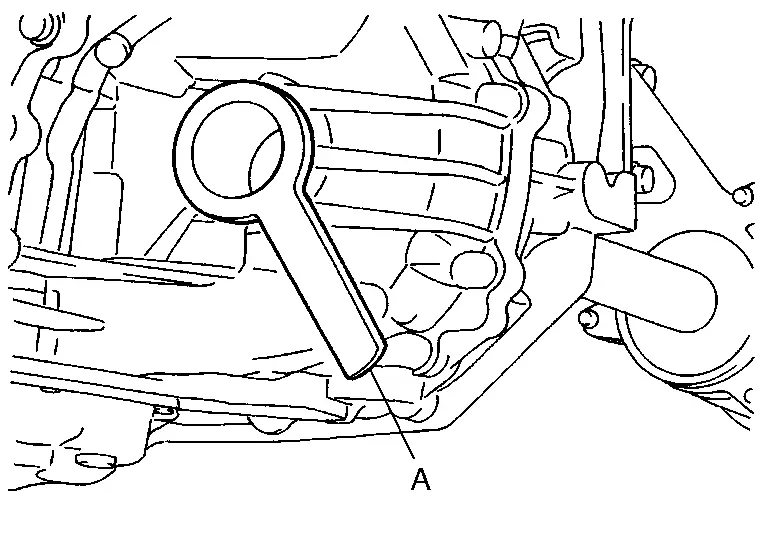

Insert suitable tool (A) between the drive shaft and the transaxle. Remove the drive shaft from the transaxle (LH/RH).

CAUTION:

-

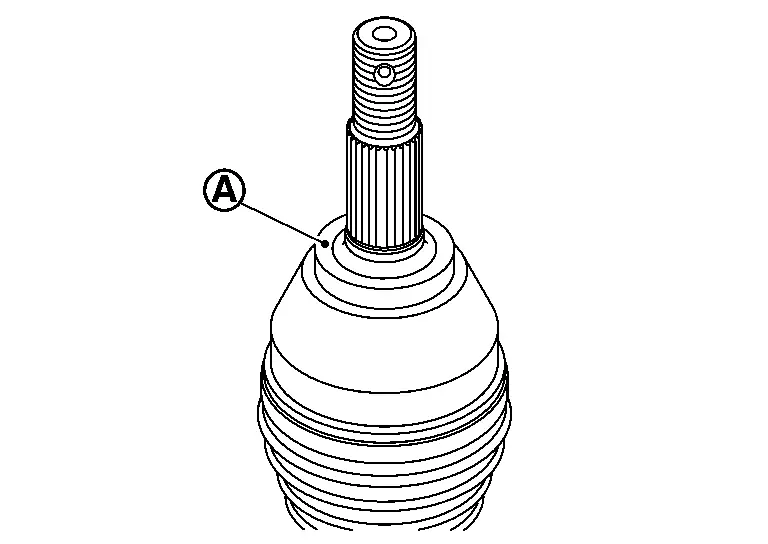

Confirm that the circular clip is attached to the drive shaft

-

Do not place the drive shaft joint at an extreme angle when removing the drive shaft. Also be careful not to overextend the slide joint.

Remove the differential side oil seal. Refer to Exploded View.

CAUTION:

Do not reuse differential side oil seal.

Remove the front under cover (RH/LH). Refer to Removal and Installation.

Remove the radiator hose (lower) from the thermostat assembly (water inlet). Refer to Exploded View.

Using a suitable tool, remove suspension member bolts and remove suspension member, engine and transmission assembly. Refer to Exploded View.

CAUTION:

-

Put a piece of wood or something similar as the supporting surface to secure a completely stable condition.

-

Confirm there is no interference with the Nissan Pathfinder vehicle.

-

Repeatedly check to ensure all harnesses are disconnected before and during engine removal.

-

Check all connection points have been disconnected.

-

Keep in mind the center of Nissan Pathfinder vehicle gravity changes. If necessary, use jack(s) to support the vehicle at rear jacking point(s) to prevent it from falling off the lift.

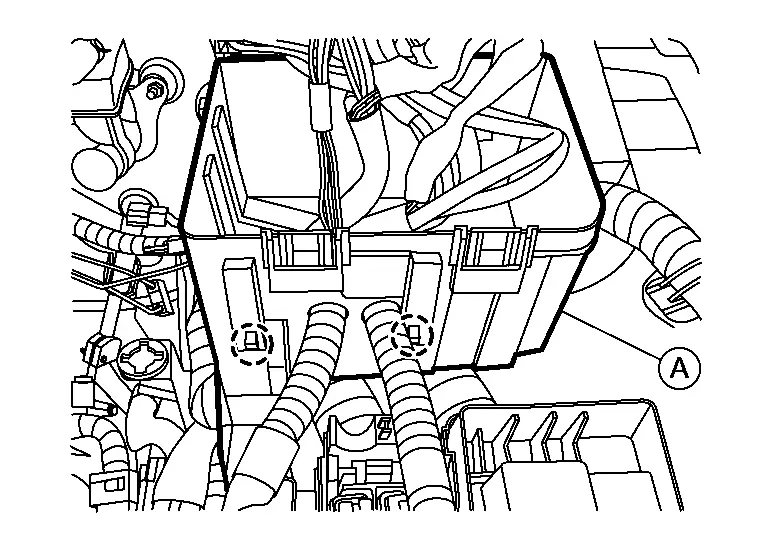

Rotate transaxle harness connector counterclockwise and disconnect transaxle harness connector.

Remove clamp and remove harness connector from oil pan. Refer to Exploded View.

Loosen the oil pan bolts, and then remove the oil pan and oil pan gasket.

NOTE:

NOTE:

Bolts cannot be removed from oil pan.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

-

Do not reuse O-ring.

-

Completely clean the iron powder from the magnet area of oil pan and the magnets.

Install the oil pan to the transaxle case with the following procedure.

-

Install the oil pan gasket to the oil pan.

CAUTION:

Completely wipe out any moisture, oil, and old gasket from the oil pan gasket surface and bolt hole of oil pan and transaxle case.

-

Install the oil pan assembly to the transaxle case, and then tighten the oil pan bolts to specification in sequence as shown.

Oil pan bolts : 9 N·m (0.9 kg-m, 80 in-lb)

-

After installation of engine and transaxle assembly, refer to Inspection.

-

Refill the engine coolant. Refer to Refilling.

-

Recharge refrigerant. Refer to Charge Refrigerant.

CAUTION:

After charging refrigerant, check for leaks. Refer to Leak Test.

-

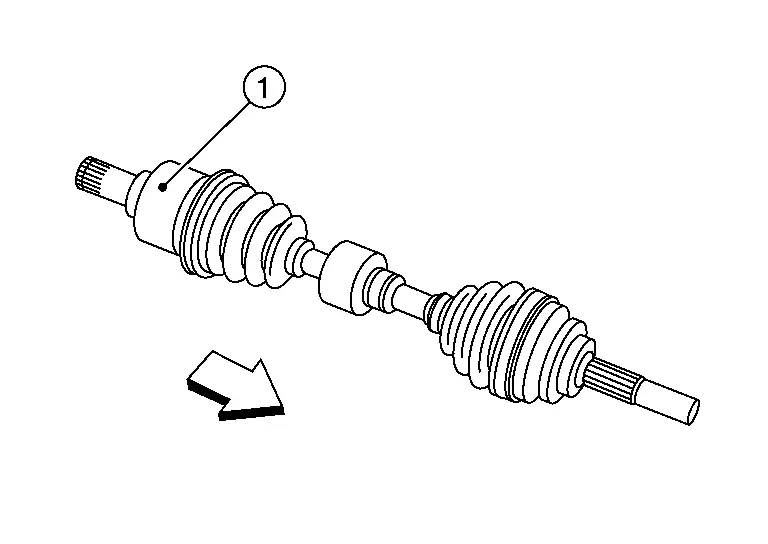

When installing the drive shaft (RH/LH), note the following:

-

Install a new differential side oil seal. Refer to Removal and Installation (LH) or Removal and Installation (RH).

-

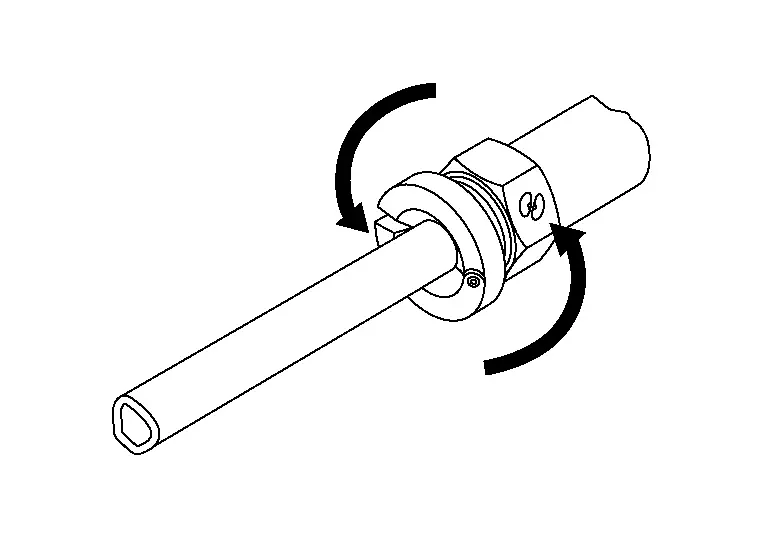

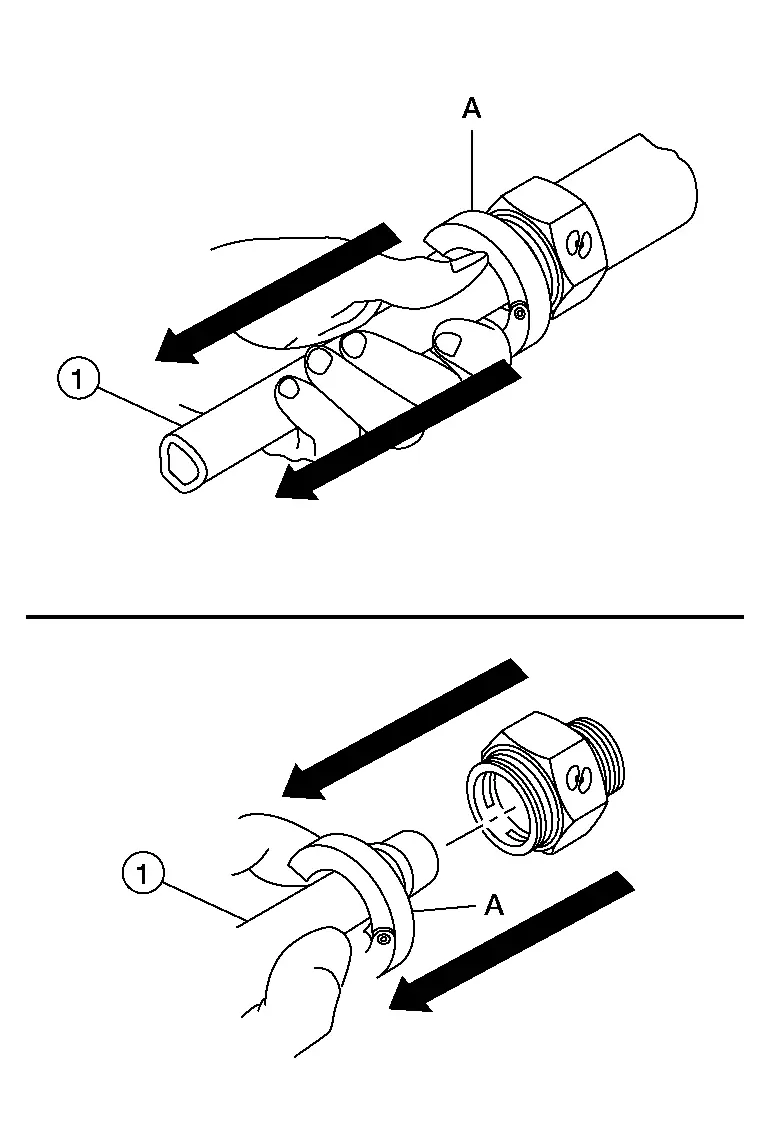

In order to prevent damage to differential side oil seal, place Tool (A) onto oil seal before inserting drive shaft as shown. Slide drive shaft into slide joint and tap with a suitable tool to install securely.

Tool number : KV38107900 (NI-52469-1) -

Install new circlip on drive shaft in the circular clip groove on transaxle side. Refer to Disassembly and Assembly (LH).

WARNING:

Ensure that circular clip is properly engaged, otherwise the joint subassembly could pull away from transaxle during Nissan Pathfinder vehicle operation resulting in loss of drive force and possible drive shaft damage, which may cause a crash and serious injury or damage the drive shaft.

NOTE:

NOTE: To ensure the circular clip is properly engaged, grasp the housing (1) and pull back and forth in axial direction while listening for clicking sounds.

Pull the joint sub-assembly in the axial direction away from transaxle assembly (

). Confirm that the joint sub assembly cannot be pulled out.

). Confirm that the joint sub assembly cannot be pulled out. -

Clean the matching surface of drive shaft and wheel hub assembly. Apply a moderate coat of paste [service parts (440037S000)] to surface (A) of joint sub-assembly of drive shaft.

NOTE:

NOTE: To avoid damage to the Nissan Pathfinder vehicle:

-

Apply paste to cover entire flat surface of joint sub-assembly of drive shaft.

Paste amount : 1.0 - 3.0 g (0.04 - 0.10 oz) -

Always check with the Parts Department for the latest parts information.

-

-

Hold wheel hub and bearing using a suitable tool. Tighten wheel hub lock nut.

Wheel hub lock nut : Refer to Exploded View (LH) or Exploded View (RH). WARNING:

To avoid risk of death or severe personal injury:

-

Since drive shaft is assembled by press-fitting, use a torque wrench to tighten wheel hub lock nut. Do not use a power tool.

-

Too much torque causes axle noise. Too little torque causes wheel bearing looseness.

-

Do not reuse the wheel hub lock nut.

-

-

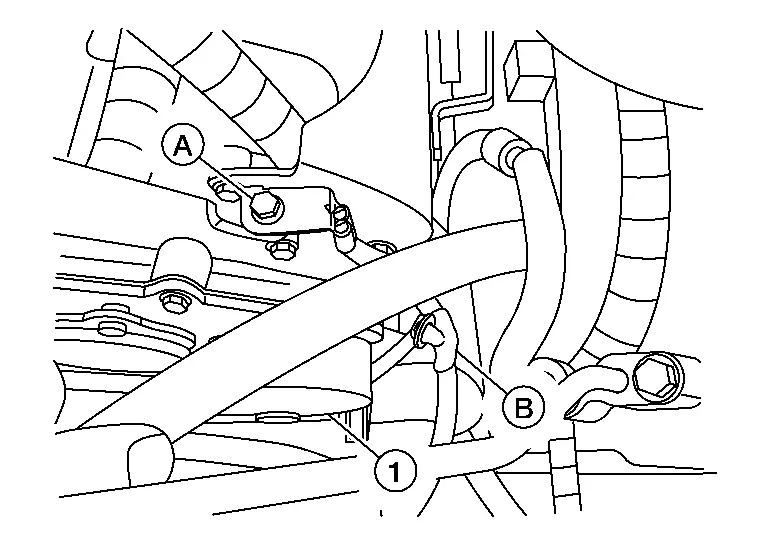

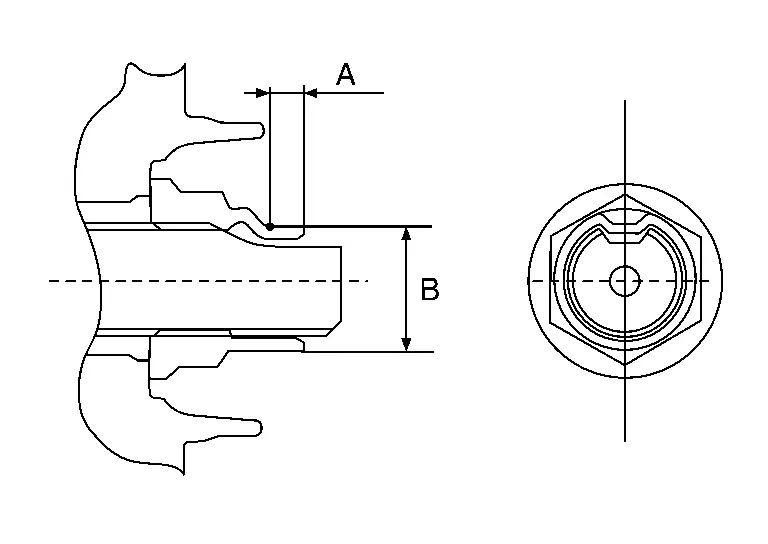

Using suitable tool (A) and cold chisel (B) stake the wheel hub lock nut (C) as shown.

WARNING:

To avoid the risk of death or severe personal injury:

-

Use the following range when staking the wheel hub lock nut.

(A) : 6.2 mm (0.244 in) (B) : 26.4 - 27.8 mm (1.039 - 1.094 in) -

-

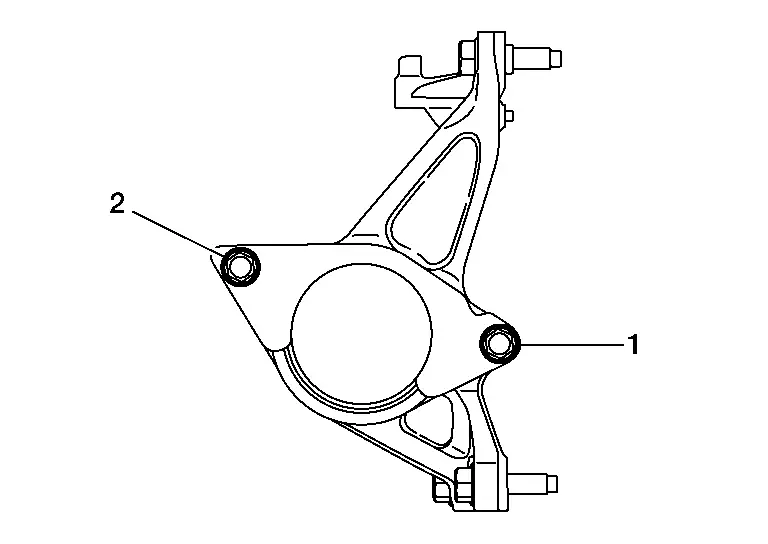

Tighten the bearing retainer bolts to the specified torque in the sequence shown.

Bearing retainer bolts : Refer to Exploded View (RH).

-

Inspection and Adjustment

INSPECTION AFTER REMOVAL

-

Check oil pan for foreign material.

-

If a large amount of worn material is found, clutch plate may be worn.

-

If iron powder is found, bearings, gears, or clutch plates may be worn.

-

If aluminum powder is found, bushing may be worn, or chips or burrs of aluminum casting parts may enter.

-

Check points where wear is found in all cases.

INSPECTION AFTER INSTALLATION

Check wheel alignment. Refer to Inspection.

Perform "ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION". Refer to Description.

When replacing or removing engine assembly, Perform "SERVICE AFTER REPLACING OR REMOVING ENGINE PARTS." Refer to Special Repair Requirement List.

Check A/T fluid level. Refer to Inspection.

Check for A/T fluid leakage. Refer to Inspection.

Nissan Pathfinder (R53) 2022-2026 Service Manual

Contact Us

Nissan Pathfinder Info Center

Email: info@nipathfinder.com

Phone: +1 (800) 123-4567

Address: 123 Pathfinder Blvd, Nashville, TN 37214, USA

Working Hours: Mon–Fri, 9:00 AM – 5:00 PM (EST)