Nissan Pathfinder: Security Control System - Dtc/circuit Diagnosis

- P161d-00 Immobilizer

- P161e-00 Immobilizer

- P161f-00 Immobilizer

- B2c20-12 Starter Control Relay

- B2c20-23 Starter Control Relay

- B2f70-01 Stop Lamp

- B2f71-23 Stop Lamp

- B2f72-23 Stop Lamp

- B2080 Power Switch

- B2033-4a Dongle Ng

- B2042-4a Electric Shift Authentication Fail

- B2043-4a Electric Shift Id Discord

- B2070-68 Key Registration

- B2090-14 Nats Antenna Amp.

- Hood Switch

- Horn Function

- Starter Cut Relay

- Stop Lamp Switch

- Brake Pedal Position Switch

P161d-00 Immobilizer Nissan Pathfinder SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| P161D-00 |

IMMOBILIZER (Immobilizer) |

Diagnosis condition | Ignition switch ON |

| Signal (terminal) | — | ||

| Threshold | When key registration has not been completed normally after replacing Intelligent Key unit. | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Improper key registration operation

-

EPS control unit

-

Intelligent Key unit

FAIL-SAFE

—

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Ignition switch ON.

-

Select “Self Diagnostic Result” mode of “ENGINE”.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

CHECK DTC PRIORITY OF INTELLIGENT KEY UNIT

If DTC P161D-00 is displayed with DTC B2033-4A, first perform the trouble diagnosis for DTC B2033-4A.

Is DTC B2033-4A detected?

YES>>Perform diagnosis of applicable. DTC B2033-4A: Refer to DTC Description.

NO>>GO TO 2.

INTELLIGENT KEY REGISTRATION

CONSULT

CONSULT

-

Perform registration of all Intelligent Keys.

For registration procedures, refer to CONSULT immobilizer mode and follow the on-screen instructions.

-

Erase DTC.

-

Perform DTC confirmation procedure for DTC P161D-00. Refer to DTC Description.

Is DTC P161D-00 detected?

YES>>GO TO 3.

NO>>Inspection End.

REPLACE INTELLIGENT KEY UNIT

-

Replace Intelligent Key unit. Refer to Removal and Installation.

-

Erase DTC.

-

Perform DTC confirmation procedure for DTC P161D-00. Refer to DTC Description.

-

Check that the DTC is not detected.

>>

Inspection End.

P161e-00 Immobilizer Nissan Pathfinder R53

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| P161E-00 |

IMMOBILIZER (Immobilizer) |

Diagnosis condition | Ignition switch ON |

| Signal (terminal) | — | ||

| Threshold | When CONSULT is not used during ECM replacement. | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Intelligent Key unit

-

ECM

FAIL-SAFE

Inhibit engine cranking

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Ignition switch ON.

-

Select “Self Diagnostic Result” mode of “ENGINE”.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

ECM REGISTRATION

CONSULT

CONSULT

Register ECM.

Is the DTC detected?

YES>>GO TO 2.

NO>>Inspection End.

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Removal and Installation.

Is the DTC detected?

YES>>GO TO 3.

NO>>Inspection End.

REPLACE ECM

Replace ECM. Refer to Removal and Installation.

>>

Inspection End.

P161f-00 Immobilizer Nissan Pathfinder 2022

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| P161F-00 |

IMMOBILIZER (Immobilizer) |

Diagnosis condition | Ignition switch ON |

| Signal (terminal) | — | ||

| Threshold | When Intelligent Key unit detects an immobilizer malfunction and engine start is prohibited. | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

ECM

FAIL-SAFE

Inhibit engine cranking

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Ignition switch ON.

-

Select “Self Diagnostic Result” mode of “ENGINE”.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

REPLACE ECM

Replace ECM. Refer to Removal and Installation.

>>

Inspection End.

B2c20-12 Starter Control Relay Nissan Pathfinder 5th Gen

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2C20-12 |

Starter control relay (Starter control relay) |

Diagnosis condition | Ignition switch ON |

| Signal (terminal) | Starter cut relay signal | ||

| Threshold | When BCM detects starter cut relay circuit is short to buttery | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connectors

(Starter cut relay circuit is short to battery)

-

Starter cut relay

FAIL-SAFE

—

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Press ignition switch under the following conditions and wait 1 second or more.

-

Selector lever: In the P position.

-

Brake pedal: Depressed.

-

-

Select “Self Diagnostic Result” mode of “BCM”.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

CHECK STARTER CUT RELAY INPUT SIGNAL

Check voltage between BCM harness connector and ground.

| (+) | (-) | Condition |

Voltage (Approx.) | |

|---|---|---|---|---|

| BCM | ||||

| Connector | Terminal | |||

| M80 | 123 | Ground | Other than following | Battery voltage |

| At engine cranking | 0 V | |||

Is the inspection result normal?

YES>>Inspection End.

NO>>GO TO 2.

CHECK STARTER CUT RELAY INPUT SIGNAL CIRCUIT

-

Ignition switch OFF.

-

Disconnect BCM connector and starter cut relay connector.

-

Check continuity between BCM harness connector and starter cut relay harness connector.

BCM Starter cut relay Continuity Connector Terminal Connector Terminal M80 123 E36 8 Yes -

Check continuity between BCM harness connector and ground.

BCM (–) Continuity Connector Terminal M80 123 Ground No

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

CHECK STARTER CUT RELAY

Check starter cut relay. Refer to Component Inspection.

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace starter cut relay.

B2c20-23 Starter Control Relay Nissan Pathfinder 2022

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2C20-23 |

Starter control relay (Starter control relay) |

Diagnosis condition | Ignition switch ON |

| Signal (terminal) |

|

||

| Threshold | When the starter cut relay status signal transmitted from IPDM E/R via CAN communication is OFF after even though BCM is operating the starter cut relay ON output. | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connectors

(The CAN communication line is open or shorted)

-

Harness or connectors

(Starter cut relay circuit is short to ground or open)

-

Starter cut relay

FAIL-SAFE

—

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Press ignition switch under the following conditions and wait 1 second or more.

-

Selector lever: In the P position.

-

Brake pedal: Depressed.

-

-

Select “Self Diagnostic Result” mode of “BCM”.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

CHECK STARTER CUT RELAY INPUT SIGNAL

Check voltage between BCM harness connector and ground.

| (+) | (-) | Condition |

Voltage (Approx.) | |

|---|---|---|---|---|

| BCM | ||||

| Connector | Terminal | |||

| M80 | 123 | Ground | Other than following | Battery voltage |

| At engine cranking | 0 V | |||

Is the inspection result normal?

YES>>GO TO 4.

NO>>GO TO 2.

CHECK STARTER CUT RELAY INPUT SIGNAL CIRCUIT

-

Ignition switch OFF.

-

Disconnect BCM connector and starter cut relay connector.

-

Check continuity between BCM harness connector and starter cut relay harness connector.

BCM Starter cut relay Continuity Connector Terminal Connector Terminal M80 123 E36 8 Yes -

Check continuity between BCM harness connector and ground.

BCM — Continuity Connector Terminal M80 123 Ground No

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

CHECK FUSIBLE LINK

Check that the following fusible link is not blown (open).

| Signal name | Fusible link | Capacity |

|---|---|---|

| Battery power supply | R | 30 A |

Is the fusible link blown (open)?

YES>>Replace the blown (open) fusible link after repairing the affected circuit if a fusible link is blown (open).

NO>>GO TO 6.

CHECK STARTER CUT RELAY OUTPUT SIGNAL

Check voltage between IPDM E/R harness connector and ground.

| (+) | (-) | Condition |

Voltage (Approx.) | |

|---|---|---|---|---|

| IPDM E/R | ||||

| Connector | Terminal | |||

| E77 | 86 | Ground | Other than at engine cranking | Less than 4 V (IPDM E/R always outputs the voltage to detect the ON/ OFF state of starter cut relay) |

| At engine cranking | Battery voltage | |||

Is the inspection result normal?

YES>>Inspection End.

NO>>GO TO 5.

CHECK STARTER CUT RELAY OUTPUT SIGNAL CIRCUIT

-

Ignition switch OFF.

-

Disconnect IPDM E/R connector and starter cut relay connector.

-

Check continuity between IPDM E/R harness connector and starter cut relay harness connector.

IPDM E/R Starter cut relay Continuity Connector Terminal Connector Terminal E77 86 E36 6 Yes -

Check continuity between IPDM E/R harness connector and ground.

IPDM E/R — Continuity Connector Terminal E77 86 Ground No

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair or replace harness.

CHECK STARTER CUT RELAY

Check starter cut relay. Refer to Component Inspection.

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace starter cut relay.

B2f70-01 Stop Lamp Nissan Pathfinder 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2F70-01 |

Stop lamp (Stop lamp) |

Diagnosis condition | When brake pedal is depressed |

| Signal (terminal) |

|

||

| Threshold | BCM makes a comparison between stop lamp switch 1 signal and stop lamp switch 2 signal. It judges from their values to detect the malfunctioning circuit 10 consecutive times | ||

| Diagnosis delay time | Depress brake pedal 10 times | ||

POSSIBLE CAUSE

-

Harness or connectors

(Stop lamp switch circuit is open or shorted)

-

Stop lamp switch

-

Fuse

FAIL-SAFE

—

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Depress brake pedal 10 times.

-

Ignition switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “BCM”.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

CHECK BRAKE PEDAL POSITION SWITCH

CONSULT

CONSULT

-

Select “Brake switch 1” and “Brake switch 2” in “Data Monitor” mode of “SIGNAL BUFFER” of “BCM”.

-

Check “Brake switch 1” and “Brake switch 2” indication under the following condition.

| Monitor item | Condition | Indication | |

|---|---|---|---|

| Brake switch 1 | Brake pedal | Depressed | Off |

| Not depressed | On | ||

| Brake switch 2 | Depressed | On | |

| Not depressed | Off | ||

Is the indication normal?

YES>>Brake pedal position switch is OK.

NO>>Brake switch 1: GO TO 2.

NO>>Brake switch 2: GO TO 7.

CHECK FUSE

Check that the following fuse is not blown (open).

| Signal name | Fuse No. | Capacity |

|---|---|---|

| Battery power supply | 32 | 10 A |

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after replacing the cause of blown (open).

NO>>GO TO 3.

CHECK BRAKE PEDAL POSITION SWITCH SIGNAL

-

Ignition switch OFF.

-

Disconnect BCM connector.

-

Ignition switch ON.

-

Check voltage between BCM harness connector and ground.

(+) (–) Condition Voltage

(Approx.)BCM Connector Terminal M80 111 Ground Brake pedal position switch 1 ON (brake pedal is not depressed) Battery voltage Brake pedal position switch 1 OFF (brake pedal is depressed) 0 V

Is the inspection normal?

YES>>Inspection End.

NO>>GO TO 4.

CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

-

Ignition switch OFF.

-

Disconnect brake pedal position switch connector.

-

Ignition switch ON.

-

Check voltage between brake pedal position switch harness connector and ground.

(+) (–) Voltage

(Approx.)Brake pedal position switch Connector Terminal E76 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 5.

NO>>Check harness for open or short between brake pedal position switch and fuse.

CHECK BRAKE PEDAL POSITION SWITCH SIGNAL CIRCUIT

-

Ignition switch OFF.

-

Check continuity between brake pedal position switch harness connector and BCM harness connector.

Brake pedal position switch BCM Continuity Connector Terminal Connector Terminal E76 2 M80 111 Yes -

Check continuity between brake pedal position switch harness connector and ground.

Brake pedal position switch (–) Continuity Connector Terminal E76 2 Ground No

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair or replace harness.

CHECK BRAKE PEDAL POSITION SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace brake pedal position switch. Refer to Exploded View.

CHECK FUSE

Check that the following fuse is not blown (open).

| Signal name | Fuse No. | Capacity |

|---|---|---|

| Battery power supply | 21 | 10 A |

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after replacing the cause of blown (open).

NO>>GO TO 8.

CHECK STOP LAMP SWITCH SIGNAL

-

Ignition switch OFF.

-

Disconnect BCM connector.

-

Check voltage between BCM harness connector and ground.

(+) (–) Condition Voltage

(Approx.)BCM Connector Terminal M80 110 Ground Brake pedal position switch 2 ON (brake pedal is depressed) Battery voltage Brake pedal position switch 2 OFF (brake pedal is not depressed) 0 V

Is the inspection normal?

YES>>Inspection End.

NO>>GO TO 9.

CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

-

Disconnect stop lamp switch connector.

-

Check voltage between stop lamp switch harness connector and ground.

(+) (–) Voltage

(Approx.)Stop lamp switch Connector Terminal E38 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 10.

NO>>Check harness for open or short between stop lamp switch and fuse.

CHECK STOP LAMP SWITCH SIGNAL CIRCUIT

-

Check continuity between stop lamp switch harness connector and BCM harness connector.

Stop lamp switch BCM Continuity Connector Terminal Connector Terminal E38 2 M80 110 Yes -

Check continuity between stop lamp switch harness connector and ground.

Stop lamp switch (–) Continuity Connector Terminal E38 2 Ground No

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair or replace harness.

B2f71-23 Stop Lamp Nissan Pathfinder 2026

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2F71-23 |

Stop lamp (Stop lamp) |

Diagnosis condition | When brake pedal is depressed |

| Signal (terminal) | Stop lamp switch 1 signal | ||

| Threshold | When stop lamp switch 1 signal is not input when brake pedal depressed. | ||

| Diagnosis delay time | 10 times or more | ||

POSSIBLE CAUSE

-

Harness or connectors

(Stop lamp switch circuit is short to battery)

-

Stop lamp switch

-

Fuse

-

BCM

FAIL-SAFE

—

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Depress brake pedal 10 times or more.

-

Ignition switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “BCM”.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

CHECK FUSE

Check that the following fuse is not blown (open).

| Signal name | Fuse No. | Capacity |

|---|---|---|

| Battery power supply | 32 | 10 A |

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after replacing the cause of blown (open).

NO>>GO TO 2.

CHECK BRAKE PEDAL POSITION SWITCH SIGNAL

-

Ignition switch OFF.

-

Disconnect BCM connector.

-

Ignition switch ON.

-

Check voltage between BCM harness connector and ground.

(+) (–) Condition Voltage

(Approx.)BCM Connector Terminal M80 111 Ground Brake pedal position switch 1 ON (brake pedal is not depressed) Battery voltage Brake pedal position switch 1 OFF (brake pedal is depressed) 0 V

Is the inspection normal?

YES>>Replace BCM. Refer to Removal and Installation.

NO>>GO TO 3.

CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

-

Ignition switch OFF.

-

Disconnect brake pedal position switch connector.

-

Ignition switch ON.

-

Check voltage between brake pedal position switch harness connector and ground.

(+) (–) Voltage

(Approx.)Brake pedal position switch Connector Terminal E76 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 4.

NO>>Check harness for open or short between brake pedal position switch and fuse.

CHECK BRAKE PEDAL POSITION SWITCH SIGNAL CIRCUIT

-

Ignition switch OFF.

-

Check continuity between brake pedal position switch harness connector and BCM harness connector.

Brake pedal position switch BCM Continuity Connector Terminal Connector Terminal E76 2 M80 111 Yes -

Check continuity between brake pedal position switch harness connector and ground.

Brake pedal position switch — Continuity Connector Terminal E76 2 Ground No

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair or replace harness.

CHECK BRAKE PEDAL POSITION SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>Replace BCM. Refer to Removal and Installation.

NO>>Replace brake pedal position switch. Refer to Exploded View.

B2f72-23 Stop Lamp Nissan Pathfinder

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2F72-23 |

Stop lamp (Stop lamp) |

Diagnosis condition | Ignition switch ON |

| Signal (terminal) | Stop lamp switch 2 signal | ||

| Threshold | When stop lamp switch 2 signal is input even though the brake pedal is not depressed 10 consecutive times. | ||

| Diagnosis delay time | Depress brake pedal 10 times | ||

POSSIBLE CAUSE

-

Harness or connectors

(Stop lamp switch circuit is open or shorted)

-

Stop lamp switch

-

Fuse

-

BCM

FAIL-SAFE

—

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Depress brake pedal 10 times.

-

Ignition switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “BCM”.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

CHECK FUSE

Check that the following fuse is not blown (open).

| Signal name | Fuse No. | Capacity |

|---|---|---|

| Battery power supply | 21 | 10 A |

Is the fuse blown (open)?

YES>>Replace the blown (open) fuse after replacing the cause of blown (open).

NO>>GO TO 2.

CHECK STOP LAMP SWITCH SIGNAL

-

Ignition switch OFF.

-

Disconnect BCM connector.

-

Check voltage between BCM harness connector and ground.

(+) (–) Condition Voltage

(Approx.)BCM Connector Terminal M80 110 Ground Stop lamp switch 2 ON (brake pedal is depressed) Battery voltage Stop lamp switch 2 OFF (brake pedal is not depressed) 0 V

Is the inspection normal?

YES>>Replace BCM. Refer to Removal and Installation.

NO>>GO TO 3.

CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

-

Disconnect stop lamp switch connector.

-

Check voltage between stop lamp switch harness connector and ground.

(+) (–) Voltage

(Approx.)Stop lamp switch Connector Terminal E38 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 4.

NO>>Check harness for open or short between stop lamp switch and fuse.

CHECK STOP LAMP SWITCH SIGNAL CIRCUIT

-

Check continuity between stop lamp switch harness connector and BCM harness connector.

Stop lamp switch BCM Continuity Connector Terminal Connector Terminal E38 2 M80 110 Yes -

Check continuity between stop lamp switch harness connector and ground.

Stop lamp switch — Continuity Connector Terminal E38 2 Ground No

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair or replace harness.

CHECK STOP LAMP SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>Replace BCM. Refer to Removal and Installation.

NO>>Replace stop lamp switch. Refer to Exploded View.

B2080 Power Switch Nissan Pathfinder SUV

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC Detection Condition | |

|---|---|---|---|

| B2080-01 |

Power switch (Power switch) |

Diagnosis condition | When the ignition switch is ON. |

| Signal (terminal) | — | ||

| Threshold | Intelligent Key unit detects the push-button ignition switch stuck at ON for 100 seconds or more | ||

| Diagnosis delay time | 100 seconds | ||

| B2080-1C |

Power switch (Power switch) |

Diagnosis condition | When the ignition switch is ON. |

| Signal (terminal) | — | ||

| Threshold | Intelligent Key unit detects the push-button ignition switch stuck at ON for 100 seconds or more | ||

| Diagnosis delay time | 100 seconds | ||

| B2080-12 |

Power switch (Power switch) |

Diagnosis condition | When the ignition switch is ON. |

| Signal (terminal) | — | ||

| Threshold | Intelligent Key unit detects the push-button ignition switch stuck at ON for 100 seconds or more | ||

| Diagnosis delay time | 100 seconds | ||

| B2080-14 |

Power switch (Power switch) |

Diagnosis condition | When the ignition switch is ON. |

| Signal (terminal) | — | ||

| Threshold | Intelligent Key unit detects the push-button ignition switch stuck at ON for 100 seconds or more | ||

| Diagnosis delay time | 100 seconds | ||

POSSIBLE CAUSE

-

Harness or connectors

(Push-button ignition switch circuit is shorted.)

-

Push-button ignition switch

-

Intelligent Key unit

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Press push-button ignition switch under the following condition:

-

Brake pedal: Not depressed

-

-

Release push-button ignition switch and wait 100 seconds or more.

-

Select “Self Diagnostic Result” mode of “INTELLIGENT KEY”.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

CHECK PUSH-BUTTON IGNITION SWITCH INPUT SIGNAL

-

Ignition switch OFF.

-

Disconnect push-button ignition switch connector.

-

Check voltage between push-button ignition switch harness connector and ground.

(+) (–) Voltage

(Approx.)Push-button ignition switch Connector Terminal M17 8 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 4.

NO>>GO TO 2.

CHECK PUSH-BUTTON IGNITION SWITCH CIRCUIT

-

Disconnect Intelligent Key unit connector.

-

Check continuity between push-button ignition switch harness connector and Intelligent Key unit harness connector.

Push-button ignition switch Intelligent Key unit Continuity Connector Terminal Connector Terminal M17 8 M38 9 Yes -

Check continuity between push-button ignition switch harness connector and ground.

Push-button ignition switch (–) Continuity Connector Terminal M17 8 Ground No

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Removal and Installation.

>>

Inspection End.

CHECK PUSH-BUTTON IGNITION SWITCH GROUND CIRCUIT

Check continuity between push-button ignition switch harness connector and ground.

| Push-button ignition switch | (–) | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| M17 | 4 | Ground | Yes |

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair or replace harness.

CHECK PUSH-BUTTON IGNITION SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Replace push-button ignition switch. Refer to Removal and Installation.

CHECK INTERMITTENT INCIDENT

Refer to Intermittent Incident.

>>

Inspection End.

Component Inspection

CHECK PUSH-BUTTON IGNITION SWITCH

-

Ignition switch OFF.

-

Disconnect push-button ignition switch connector.

-

Check continuity between push-button ignition switch terminals.

Push-button ignition switch Condition Continuity Terminals 4 8 Push-button ignition switch Pressed Yes Not pressed No

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace push-button ignition switch. Refer to Removal and Installation.

B2033-4a Dongle Ng Nissan Pathfinder R53

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detection condition | |

|---|---|---|---|

| B2033–4A |

DONGLE NG (Dongle not good) |

Diagnosis condition | Ignition switch ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | The ID verification results NG | ||

| Diagnosis delay time | 1 second or more | ||

POSSIBLE CAUSE

-

Harness or connector

(The CAN communication line is open or shorted)

-

Intelligent Key unit

-

EPS control unit

FAIL-SAFE

—

DTC CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Ignition switch ON.

-

Select “Self Diagnostic Result” mode of “HANDS FREE MODULE”.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

PERFORM INITIALIZATION

CONSULT

CONSULT

-

Perform initialization of Intelligent Key unit and registration of all Intelligent Keys.

For initialization and registration procedures, refer to CONSULT immobilizer mode and follow the on-screen instructions.

-

Check that the Nissan Pathfinder vehicle can be set to READY using registered Intelligent Key.

Is the inspection result normal?

YES>>Inspection End.

NO>>GO TO 2.

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Removal and Installation.

Is the DTC detected?

YES>>GO TO 3.

NO>>Inspection End.

REPLACE EPS CONTROL UNIT

Replace EPS control unit. Refer to Removal and Installation.

>>

Inspection End.

B2042-4a Electric Shift Authentication Fail Nissan Pathfinder 2022

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2042–4A |

Electric shift authentication fail (Electric shift authentication fail) |

Diagnosis condition | When ignition switch is placed from OFF to ON |

| Signal (terminal) | CAN communication signal | ||

| Threshold | When Intelligent Key unit cannot detect CAN communication with electric shift control module | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connectors

(The CAN communication line is open or shorted)

-

Electric shift control module

FAIL-SAFE

Prohibit shifting the shift selector from P position

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Ignition switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “HANDS FREE MODULE”.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

CHECK DTC PRIORITY OF INTELLIGENT KEY UNIT

CONSULT

CONSULT

-

Select “Self Diagnostic Result” mode of “HANDS FREE MODULE”.

-

If DTC B2042–4A is displayed with two or more DTCs are detected, refer to DTC inspection priority chart, and determine trouble diagnosis.

Is applicable DTC detected?

YES>>Perform the trouble diagnosis related to the detected DTC. Refer to DTC Index.

NO>>GO TO 2.

CHECK DTC PRIORITY OF ELECTRIC SHIFT CONTROL MODULE

CONSULT

CONSULT

Select “Self Diagnostic Result” mode of “SHIFT”.

Is the DTC detected?

YES>>Perform the trouble diagnosis related to the detected DTC. Refer to DTC Index.

NO>>Replace electric shift control module. Refer to Removal and Installation.

B2043-4a Electric Shift Id Discord Nissan Pathfinder R53

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2043–4A |

Electric shift ID discord (Electric shift identification discord) |

Diagnosis condition | When registering electric shift control module |

| Signal (terminal) | CAN communication signal | ||

| Threshold | Electric shift control module registration has not been completed normally | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

Improper electric shift control module registration operation

FAIL-SAFE

Prohibit shifting the shift selector from P position

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Ignition switch ON.

-

Check DTC in “Self Diagnostic Result” mode of “HANDS FREE MODULE”.

Is DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

REPLACE ELECTRIC SHIFT CONTROL MODULE

Replace electric shift control module. Refer to Removal and Installation.

>>

Inspection End.

B2070-68 Key Registration Nissan Pathfinder 2022

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2070–68 |

Key registration (Key registration) |

Diagnosis condition | All time |

| Signal (terminal) | — | ||

| Threshold | Intelligent Key that does not match the Nissan Pathfinder vehicle is registered. | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Improper registration operation

-

Intelligent Key

-

Intelligent Key unit

FAIL-SAFE

—

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Perform initialization of Intelligent Key unit and registration of all Intelligent Keys.

-

Select “Self Diagnostic Result” mode of “HANDS FREE MODULE”.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

REPLACE INTELLIGENT KEY

CONSULT

CONSULT

-

Replace Intelligent Key that matches the Nissan Pathfinder vehicle.

-

Perform initialization of Intelligent Key unit and registration of Intelligent Key.

Is the inspection result normal?

YES>>Inspection End.

NO>>GO TO 2.

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Removal and Installation.

>>

Inspection End.

B2090-14 Nats Antenna Amp. Nissan Pathfinder Fifth generation

DTC Description

DTC DETECTION LOGIC

| DTC No. |

CONSULT screen items (Trouble diagnosis content) | DTC detecting condition | |

|---|---|---|---|

| B2090–14 |

NATS antenna amp. (Nissan anti-theft system antenna amplifier) |

Diagnosis condition | Work support ‟INSIDE/OUTSIDE ANT DIAGNOSIS”: activated |

| Signal (terminal) | NATS antenna amp. signal | ||

| Threshold | Inactive communication between NATS antenna amp. and Intelligent Key unit | ||

| Diagnosis delay time | 1 second or less | ||

POSSIBLE CAUSE

-

Harness or connectors

(NATS antenna amp. circuit is open or shorted.)

-

Push-button ignition switch (NATS antenna amp.)

-

Intelligent Key unit

FAIL-SAFE

—

CONFIRMATION PROCEDURE

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

-

Select “INSIDE/OUTSIDE ANT DIAGNOSIS” in “WORK SUPPORT” mode of “HANDS FREE MODULE”.

-

Select “Self Diagnostic Result” mode of “HANDS FREE MODULE”.

Is the DTC detected?

YES>>Refer to DTC Diagnosis Procedure.

NO>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO>>Confirmation after repair: Inspection End.

DTC Diagnosis Procedure

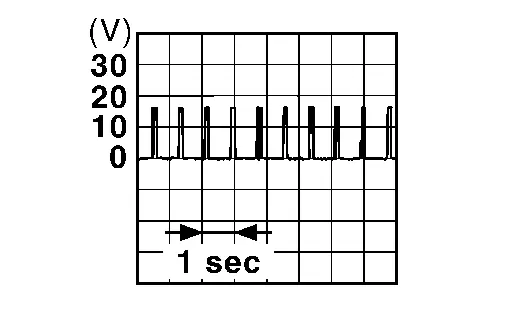

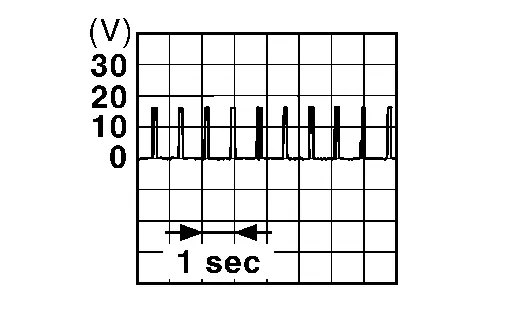

CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL

Check signal between push-button ignition switch harness connector and ground using an oscilloscope.

| (+) | (–) | Condition |

Signal (Reference value) | ||

|---|---|---|---|---|---|

| Push-button ignition switch | |||||

| Connector | Terminal | ||||

| M17 | 2 | Ground | Intelligent Key battery is removed and brake pedal is depressed | When a registered Intelligent Key backside is contacted to push-button ignition switch | 0 V |

| Other than above |

|

||||

| 3 | When a registered Intelligent Key backside is contacted to push-button ignition switch | 0 V | |||

| Other than above |

|

||||

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 2.

CHECK NATS ANTENNA AMP. COMMUNICATION SIGNAL CIRCUIT

-

Ignition switch OFF.

-

Disconnect Intelligent Key unit connector and push-button ignition switch connector.

-

Check continuity between push-button ignition switch harness connector and Intelligent Key unit harness connector.

Push-button ignition switch Intelligent Key unit Continuity Connector Terminal Connector Terminal M17 2 M38 19 Yes 3 20 -

Check continuity between push-button ignition switch harness connector and ground.

Push-button ignition switch (-) Continuity Connector Terminal M17 2 Ground No 3

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace harness.

REPLACE PUSH-BUTTON IGNITION SWITCH

Replace push-button ignition switch. Refer to Removal and Installation.

Is the inspection result normal?

YES>>Inspection End.

NO>>GO TO 4.

REPLACE INTELLIGENT KEY UNIT

Replace Intelligent Key unit. Refer to Removal and Installation.

>>

Inspection End.

Hood Switch Nissan Pathfinder SUV

Component Function Check

CHECK FUNCTION

CONSULT

CONSULT

-

Select “HOOD SW (CAN)” or “Hood switch” in “Data Monitor” mode of “IPDM E/R”.

-

Check “HOOD SW (CAN)” or “Hood switch” indication under the following condition.

| Monitor item | Condition | Indication |

|---|---|---|

| HOOD SW (CAN) | Close the hood | Close |

| Open the hood | Open | |

| Transmits invalid CAN signal | NG | |

| Hood switch | Close the hood | Close |

| Open the hood | Open |

Is the indication normal?

YES>>Hood switch is OK.

NO>>Refer to Diagnosis Procedure.

Diagnosis Procedure

CHECK HOOD SWITCH SIGNAL CIRCUIT 1

-

Ignition switch OFF.

-

Disconnect hood switch connector.

-

Check voltage between hood switch harness connector and ground.

| (+) | (–) |

Voltage (Approx.) | |

|---|---|---|---|

| Hood switch | |||

| Connector | Terminal | ||

| E234 | 1 | Ground | Battery voltage |

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 2.

CHECK HOOD SWITCH SIGNAL CIRCUIT 2

-

Disconnect IPDM E/R connector.

-

Check continuity between IPDM E/R harness connector and hood switch harness connector.

IPDM E/R Hood switch Continuity Connector Terminal Connector Terminal E217 52 E234 1 Yes -

Check continuity between IPDM E/R harness connector and ground.

IPDM E/R — Continuity Connector Terminal E217 52 Ground No

Is the inspection result normal?

YES>>Replace IPDM E/R. Refer to Removal and Installation.

NO>>Repair or replace harness.

CHECK HOOD SWITCH GROUND CIRCUIT

Check continuity between hood switch harness connector and ground.

| Hood switch | — | Continuity | |

|---|---|---|---|

| Connector | Terminal | ||

| E234 | 2 | Ground | Yes |

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

CHECK HOOD SWITCH

Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Replace hood lock assembly. Refer to Removal and Installation.

CHECK INTERMITTENT INCIDENT

Refer to Intermittent Incident.

>>

Inspection End.

Component Inspection

CHECK HOOD SWITCH

-

Ignition switch OFF.

-

Disconnect hood switch connector.

-

Check continuity between hood switch terminals.

Hood switch Condition Continuity Terminal 1 2 Hood lock Unlock condition No Lock condition Yes

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace hood lock assembly. Refer to Removal and Installation.

Horn Function Nissan Pathfinder

Component Function Check

CHECK FUNCTION

CONSULT

CONSULT

-

Ignition switch OFF.

-

Perform “HORN” in “ACTIVE TEST” mode of “IPDM E/R”.

-

Check the horn operation.

Test item Description HORN On Horn Sounds (for 20 ms.)

Is the operation normal?

YES>>Inspection End.

NO>>Refer to Diagnosis Procedure (Horn (Low)) or Diagnosis Procedure (Horn (High)).

Diagnosis Procedure (Horn (Low))

CHECK HORN FUNCTION

Check horn function with horn switch.

Do horns sound?

YES>>GO TO 2.

NO>>Perform the trouble diagnosis for horn circuit. Refer to Wiring Diagram.

CHECK HORN RELAY CONTROL SIGNAL

CONSULT

CONSULT

-

Ignition switch ON.

-

Select "HORN" in "ACTIVE TEST" mode of "IPDM E/R".

-

Check voltage between IPDM E/R harness connector and ground.

| (+) | (–) | Test item |

Voltage (Approx.) | ||

|---|---|---|---|---|---|

| IPDM E/R | |||||

| Connector | Terminal | ||||

| E119 | 9 | Ground | HORN | On | 0 V |

| Off | Battery voltage | ||||

Is operation normal?

YES>>GO TO 4.

NO>>GO TO 3.

CHECK IPDM E/R POWER SUPPLY CIRCUIT

-

Ignition switch OFF.

-

Disconnect horn relay-2 connector and IPDM E/R connector.

-

Check continuity between IPDM E/R harness connector and horn relay-2 harness connector.

IPDM E/R Horn relay-2 Continuity Connector Terminal Connector Terminal E119 9 E58 1 Yes -

Check continuity between IPDM E/R harness connector and ground.

IPDM E/R (–) Continuity Connector Terminal E119 9 Ground No

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

CHECK INTERMITTENT INCIDENT

Refer to Intermittent Incident.

>>

Inspection End.

Diagnosis Procedure (Horn (High))

CHECK HORN FUNCTION

Check horn function with horn switch.

Do horns sound?

YES>>GO TO 2.

NO>>Perform the trouble diagnosis for horn circuit. Refer to Wiring Diagram.

CHECK HORN RELAY CONTROL SIGNAL

CONSULT

CONSULT

-

Ignition switch ON.

-

Select "HORN" in "ACTIVE TEST" mode of "IPDM E/R".

-

Check voltage between IPDM E/R harness connector and ground.

| (+) | (–) | Test item |

Voltage (Approx.) | ||

|---|---|---|---|---|---|

| IPDM E/R | |||||

| Connector | Terminal | ||||

| E119 | 9 | Ground | HORN | On | 0 V |

| Off | Battery voltage | ||||

Is operation normal?

YES>>GO TO 4.

NO>>GO TO 3.

CHECK IPDM E/R POWER SUPPLY CIRCUIT

-

Ignition switch OFF.

-

Disconnect horn relay-1 connector and IPDM E/R connector.

-

Check continuity between IPDM E/R harness connector and horn relay-1 harness connector.

IPDM E/R Horn relay-1 Continuity Connector Terminal Connector Terminal E119 9 H-1 1 Yes -

Check continuity between IPDM E/R harness connector and ground.

IPDM E/R (–) Continuity Connector Terminal E119 9 Ground No

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace harness.

CHECK INTERMITTENT INCIDENT

Refer to Intermittent Incident.

>>

Inspection End.

Starter Cut Relay Nissan Pathfinder 5th Gen

Component Inspection

CHECK STARTER CUT RELAY

-

Ignition switch OFF.

-

Disconnect starter cut relay.

-

Check continuity between starter cut relay terminals.

Starter cut relay Condition Continuity Terminal 8 7 12 V direct current supply between terminals 5 and 6 Yes No current supply No

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace starter cut relay.

Stop Lamp Switch Nissan Pathfinder 2022

Component Inspection

CHECK STOP LAMP SWITCH

-

Ignition switch OFF.

-

Disconnect stop lamp switch connector.

-

Check continuity between stop lamp switch terminals.

Stop lamp switch Condition Continuity Terminal 1 2 Brake pedal Not depressed No Depressed Yes

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace stop lamp switch. Refer to Exploded View.

Brake Pedal Position Switch Nissan Pathfinder

Component Inspection

CHECK BRAKE PEDAL POSITION SWITCH

-

Ignition switch OFF.

-

Disconnect stop lamp switch connector.

-

Check continuity between brake pedal position switch terminals.

Brake pedal position switch Condition Continuity Terminal 1 2 Brake pedal Not depressed No Depressed Yes

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace brake pedal position switch. Refer to Exploded View.

Nissan Pathfinder (R53) 2022-2026 Service Manual

Dtc/circuit Diagnosis

- P161d-00 Immobilizer

- P161e-00 Immobilizer

- P161f-00 Immobilizer

- B2c20-12 Starter Control Relay

- B2c20-23 Starter Control Relay

- B2f70-01 Stop Lamp

- B2f71-23 Stop Lamp

- B2f72-23 Stop Lamp

- B2080 Power Switch

- B2033-4a Dongle Ng

- B2042-4a Electric Shift Authentication Fail

- B2043-4a Electric Shift Id Discord

- B2070-68 Key Registration

- B2090-14 Nats Antenna Amp.

- Hood Switch

- Horn Function

- Starter Cut Relay

- Stop Lamp Switch

- Brake Pedal Position Switch

Contact Us

Nissan Pathfinder Info Center

Email: info@nipathfinder.com

Phone: +1 (800) 123-4567

Address: 123 Pathfinder Blvd, Nashville, TN 37214, USA

Working Hours: Mon–Fri, 9:00 AM – 5:00 PM (EST)