Nissan Pathfinder: Steering System - Basic Inspection

- Heated Steering Wheel System. Diagnosis and Repair Work Flow

- Steering Wheel

- Steering Column

- Steering Gear and Linkage

Heated Steering Wheel System. Diagnosis and Repair Work Flow Nissan Pathfinder 2022

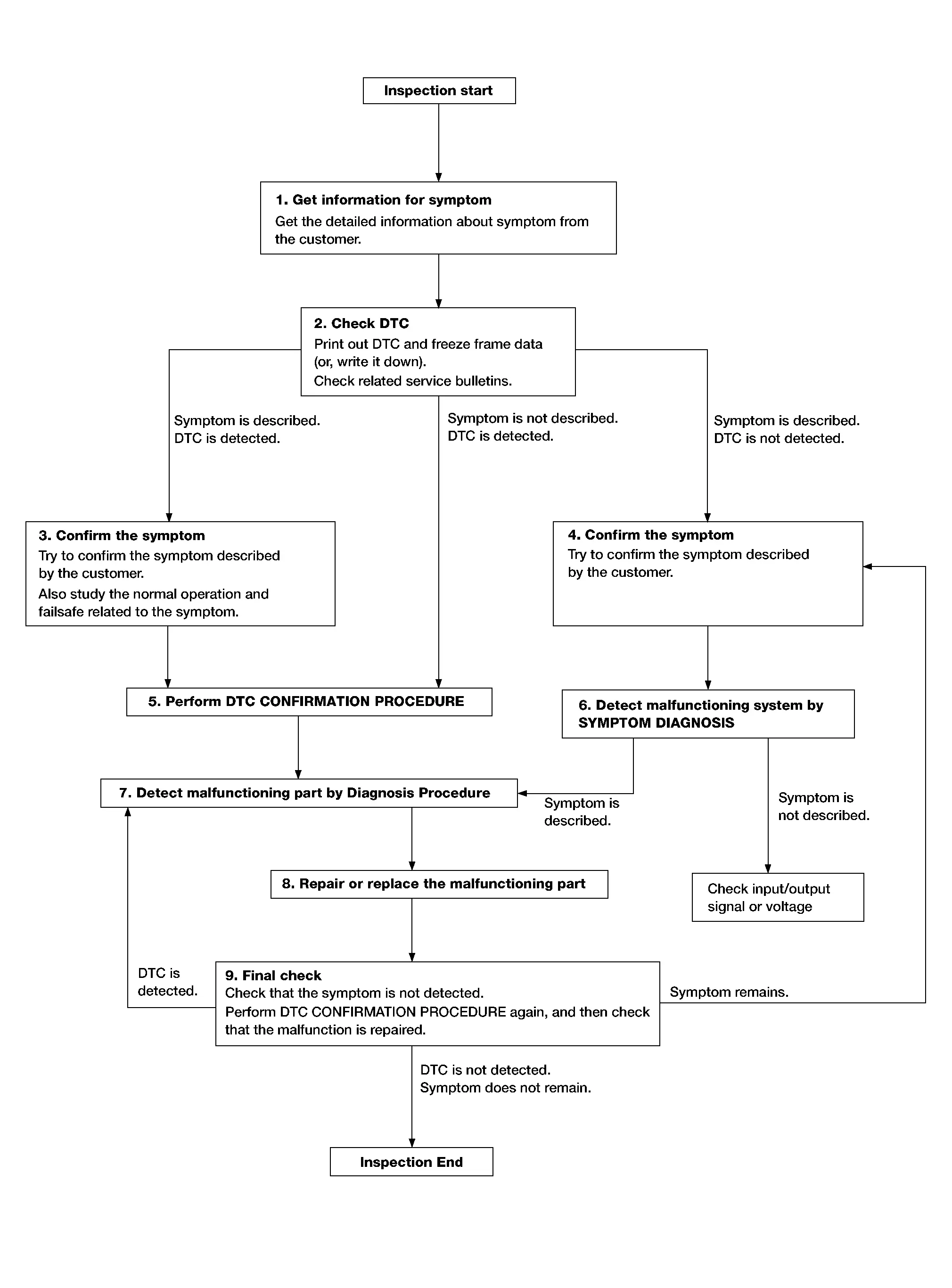

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

GET INFORMATION FOR SYMPTOM

-

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurs).

-

Check operation condition of the function that is malfunctioning.

>>

GO TO 2.

CHECK DTC

CONSULT

CONSULT

-

Check DTC.

-

Perform the following procedure if DTC is detected:

-

Record DTC and freeze frame data. (Print them out.)

-

Erase DTC.

-

Study the relationship between the cause detected by DTC and the symptom described by the customer.

-

-

Check related service bulletins for information.

Are any symptoms described and any DTC detected?

Symptom is described, DTC is detected>>GO TO 3.

Symptom is described, DTC is not detected>>GO TO 4.

Symptom is not described, DTC is detected>>GO TO 5.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Also study the normal operation and fail-safe related to the symptom.

Verify relation between the symptom and the condition when the symptom is detected.

>>

GO TO 5.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Verify relation between the symptom and the condition when the symptom is detected.

>>

GO TO 6.

PERFORM DTC CONFIRMATION PROCEDURE

CONSULT

CONSULT

Perform DTC CONFIRMATION PROCEDURE for the detected DTC, and then check that DTC is detected again. At this time, always connect CONSULT to the Nissan Pathfinder vehicle, and check "Self Diagnostic Result" in real time.

NOTE:

NOTE:

-

Freeze frame data is useful if the DTC is not detected.

-

Perform Component Function Check if DTC CONFIRMATION PROCEDURE is not included on Service Manual. This simplified check procedure is an effective alternative though DTC cannot be detected during this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC CONFIRMATION PROCEDURE.

Is DTC detected?

YES>>GO TO 7.

NO>>Refer to Intermittent Incident.

DETECT MALFUNCTIONING SYSTEM BY SYMPTOM DIAGNOSIS

Detect malfunctioning system according to SYMPTOM DIAGNOSIS based on the confirmed symptom in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

Is the symptom described?

YES>>GO TO 7.

NO>>Refer to Intermittent Incident.

DETECT MALFUNCTIONING PART BY DIAGNOSIS PROCEDURE

Inspect according to Diagnosis Procedure of the system.

Is malfunctioning part detected?

YES>>GO TO 8.

NO>>Refer to Intermittent Incident.

REPAIR OR REPLACE THE MALFUNCTIONING PART

CONSULT

CONSULT

-

Repair or replace the malfunctioning part.

-

Reconnect parts or connectors disconnected during Diagnosis Procedure again after repair and replacement.

-

Check DTC. If DTC is detected, erase it.

>>

GO TO 9.

FINAL CHECK

CONSULT

CONSULT

When DTC is detected in step 2, perform DTC CONFIRMATION PROCEDURE again, and then check that the malfunction is repaired securely.

When symptom is described by the customer, refer to confirmed symptom in step 3 or 4, and check that the symptom is not detected.

Is DTC detected and does symptom remain?

YES>>DTC is detected: GO TO 7.

YES>>Symptom remains: GO TO 4.

NO>>Before returning the Nissan Pathfinder vehicle to the customer, always erase DTC.

Steering Wheel Nissan Pathfinder 2022

Inspection

CONDITION OF INSTALLATION

-

Check installation condition of power steering gear, front suspension, front drive shaft and steering column.

-

Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial direction.

Steering wheel axial end play : Refer to Steering Wheel. -

Verify that the power steering gear nuts are tightened to specification. Refer to Installation.

STEERING WHEEL PLAY

Turn tires straight ahead, start engine, then turn steering wheel to the left and right lightly. Measure steering wheel movement on the outer circumference of the steering wheel when it is turned to the point where tires start moving.

| Steering wheel play | : Refer to Steering Wheel. |

NEUTRAL POSITION ON STEERING WHEEL

-

Check neutral position on steering wheel after confirming that front wheel alignment is correct. Refer to Inspection.

Turn tires straight ahead, check if steering wheel is in the neutral position.

If it is not in the neutral position, remove steering wheel and reinstall it correctly.

If the neutral position cannot be attained by repositioning the steering wheel two teeth or less on steering stem, loosen tie-rod lock nuts of power steering gear outer sockets, then adjust tie-rods by the same amount in the opposite direction.

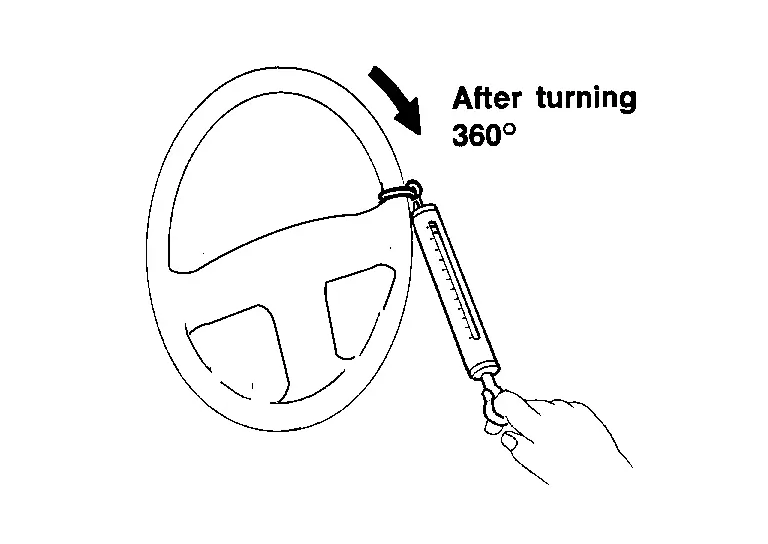

STEERING WHEEL TURNING FORCE

Park vehicle on a level, dry surface and set parking brake.

Start engine.

Verify that the tires are inflated to the specified pressure. Refer to Tire Air Pressure.

Check steering wheel turning force using Tool when steering wheel has been turned 360° from the neutral position.

| Tool number | : — (NI-44372) |

| Steering wheel turning force | : Refer to Steering Wheel. |

If steering wheel turning force is out of specification, inspect steering column. Refer to Inspection.

If steering column meets specification, inspect steering gear. Refer to Inspection.

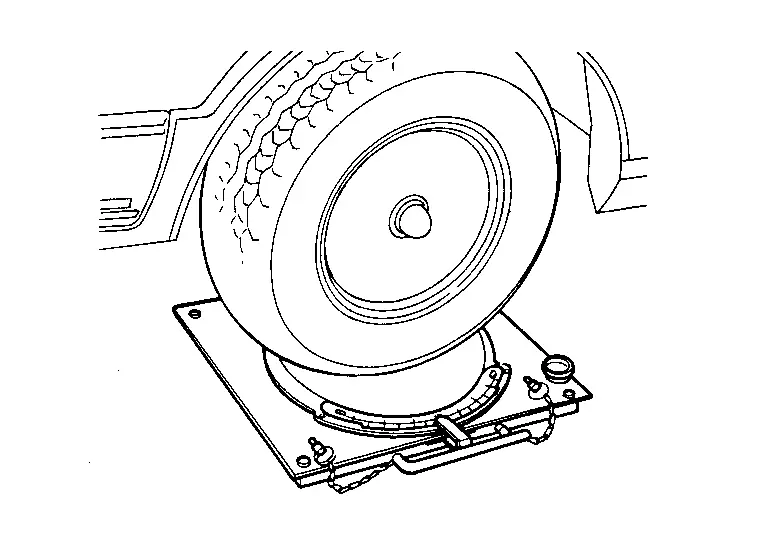

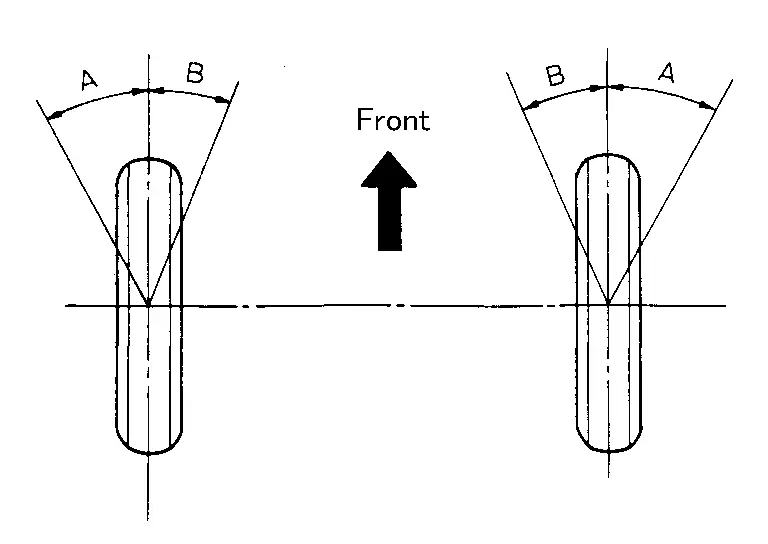

CHECKING FRONT WHEEL TURNING ANGLE

-

Check front wheel turning angle after toe-in inspection. Place front wheels on turning radius gauges and rear wheels on stands. Check the maximum inner and outer wheel turning angles for LH and RH road wheels.

-

Measure the turning angles with the engine at idle, then turn the steering wheel from full left stop to full right stop and measure the turning angle. Refer to Steering Angle.

Inner wheel angle (A) : Refer to Steering Angle. Outer wheel angle (B) : Refer to Steering Angle. -

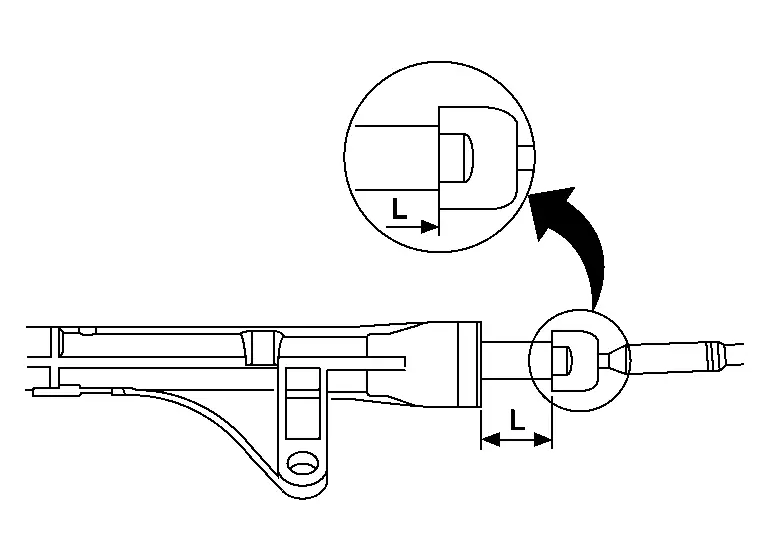

Measure the rack stroke specification with Nissan Pathfinder vehicle in neutral position. Refer to Power Steering Gear.

Rack stroke in neutral position (L) : Refer to Power Steering Gear.

Steering Column Nissan Pathfinder 2022

Inspection

HOLE COVER SEAL, HOLE COVER AND LOWER SHAFT

Check each part of hole cover seal, hole cover, steering column, and lower joint for damage or other malfunctions. Replace if necessary.

STEERING COLUMN

-

Check each part of steering column for damage or other malfunctions. Replace entire steering column if any parts are damaged.

-

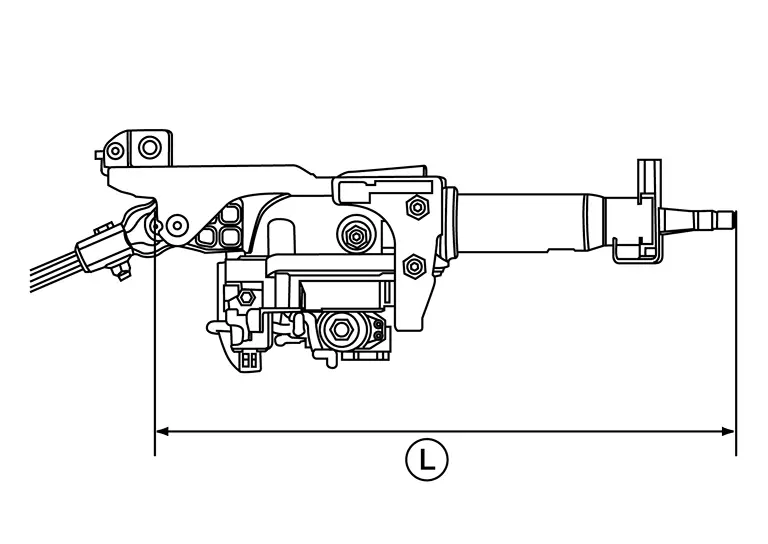

Measure the length (L) as shown if Nissan Pathfinder vehicle has been involved in a minor collision. Replace steering column if outside the specifications.

Steering column length (L) : Refer to Steering Column. -

Measure steering column rotating torque using suitable tool. Replace steering column if outside the standard.

Rotating torque : Refer to Steering Column. -

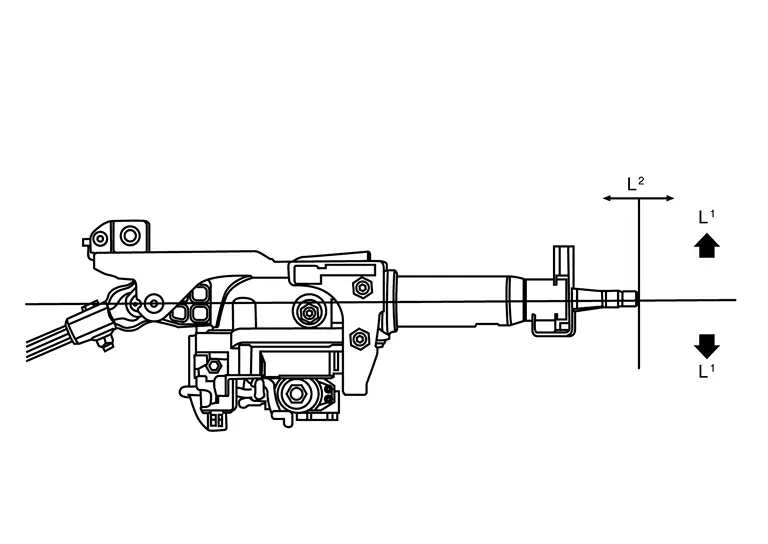

Check tilt and telescopic mechanism operating range (L1), (L2) as shown.

Tilt operating range (L1) : Refer to Steering Column. Telescopic operating range (L2) : Refer to Steering Column.

Steering Gear and Linkage Nissan Pathfinder SUV

Inspection

BOOT

Check boot for cracks. Replace if any damage is found.

OUTER SOCKET AND INNER SOCKET

-

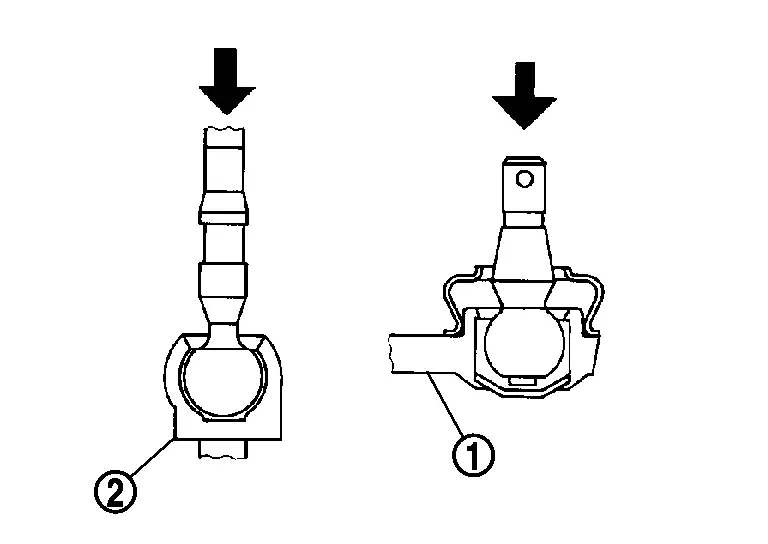

Ball joint swinging torque

-

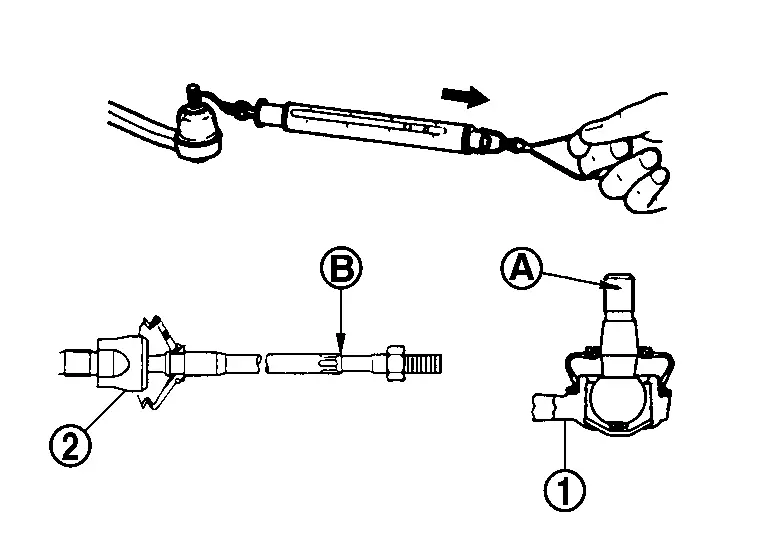

Hook the Tool at the measuring point and pull the Tool. Make sure that the Tool reads the specified value when ball stud and inner socket start to move. Replace outer socket or inner socket if the measured values are outside the standard.

Measuring point of outer socket (1) : Ball stud upper side (A) Measuring point of inner socket (2) : Point (B) as shown Tool number : — (NI-44372) Swinging torque : Refer to Power Steering Gear.

-

-

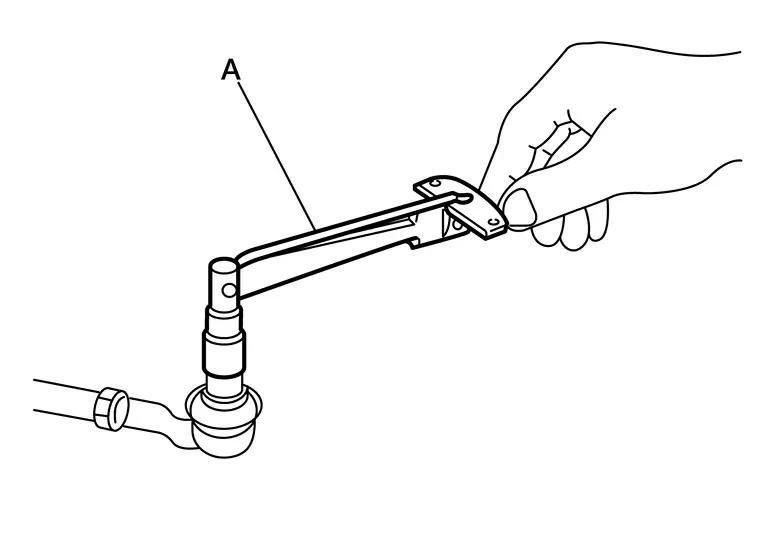

Ball joint rotating torque

-

Make sure that the reading is within the following specified range using suitable tool (A). Replace outer socket if the reading is outside the specification.

Rotating torque : Refer to Power Steering Gear.

-

-

Ball joint axial end play

-

Apply an axial load of 1960 N (200 kg, 440 lb) to ball stud. Measuring the amount of stud movement using a suitable tool, make sure that the value is within specification. Replace outer socket (1) and inner socket (2) if the measured value is outside specification.

Axial end play : Refer to Power Steering Gear.

-

Nissan Pathfinder (R53) 2022-2026 Service Manual

Basic Inspection

- Heated Steering Wheel System. Diagnosis and Repair Work Flow

- Steering Wheel

- Steering Column

- Steering Gear and Linkage

Contact Us

Nissan Pathfinder Info Center

Email: info@nipathfinder.com

Phone: +1 (800) 123-4567

Address: 123 Pathfinder Blvd, Nashville, TN 37214, USA

Working Hours: Mon–Fri, 9:00 AM – 5:00 PM (EST)