Nissan Pathfinder: Rear Axle - Rear Drive Shaft

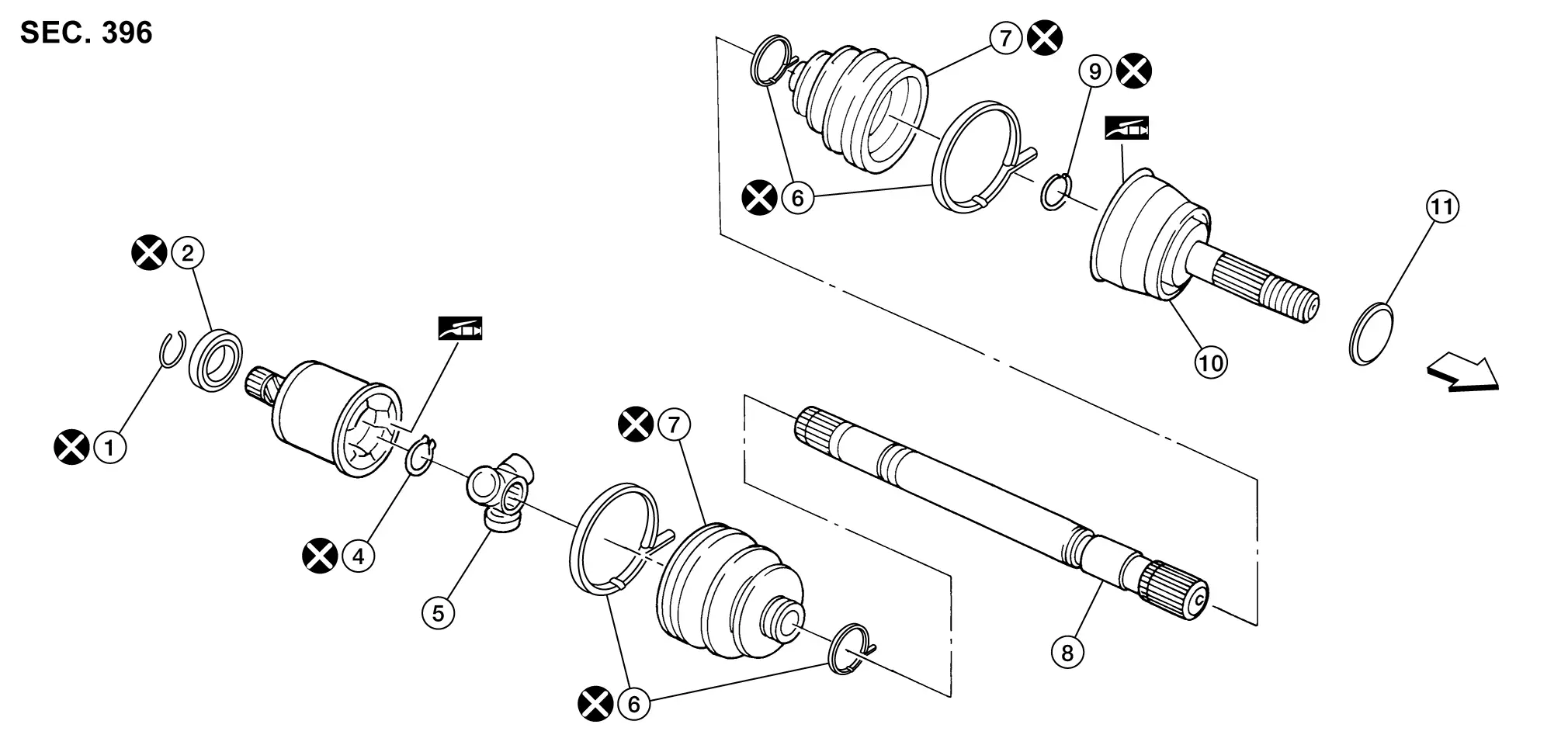

Exploded View

| 1. | Circular clip | 2. | Dust shield | 3. | Housing |

| 4. | Snap ring | 5. | Spider assembly | 6. | Boot band |

| 7. | Boot | 8. | Shaft | 9. | Circular clip |

| 10. | Joint sub-assembly | 11. | Dust shield |

|

Wheel side |

|

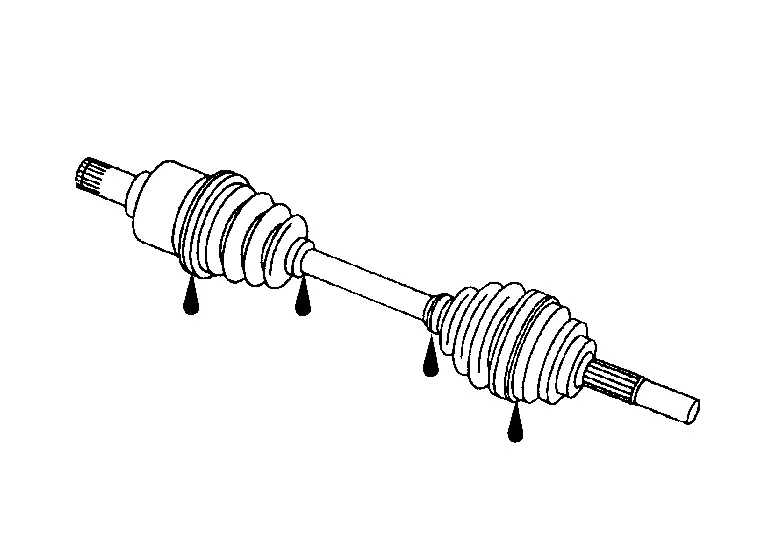

: Fill NISSAN genuine grease or an equivalent. | ||||

|

: Always replace after every disassembly. | ||||

Disassembly and Assembly

DISASSEMBLY

Final Drive Side

Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

Remove boot bands, and then remove boot from housing.

Put matching marks on housing and shaft.

CAUTION:

Use paint or an equivalent for matching marks. Never scratch the surface.

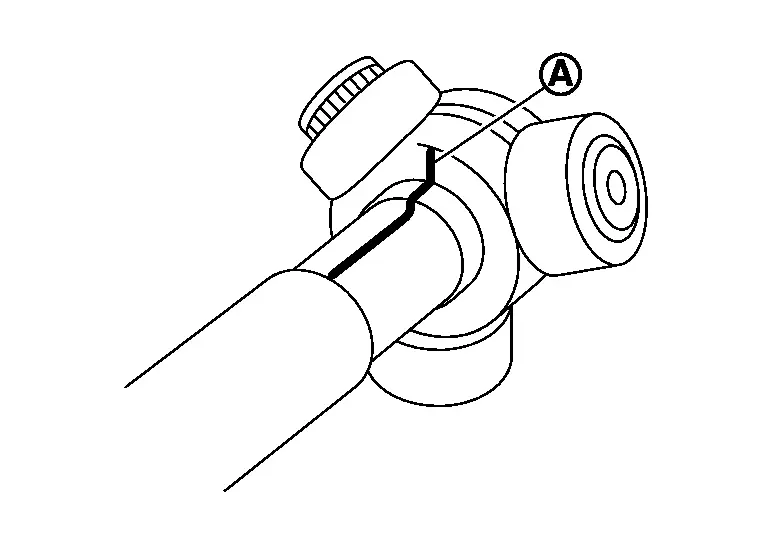

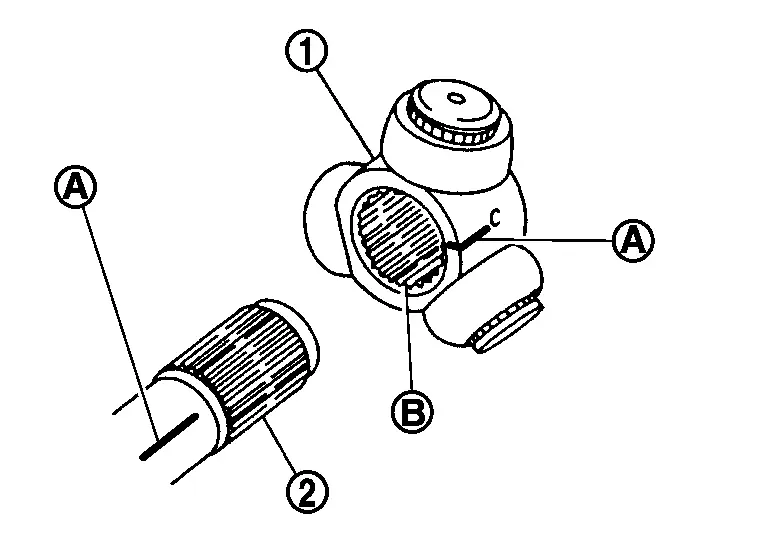

Put matching marks (A) on the spider assembly and shaft.

CAUTION:

Use paint or an equivalent for matching marks. Never scratch the surface.

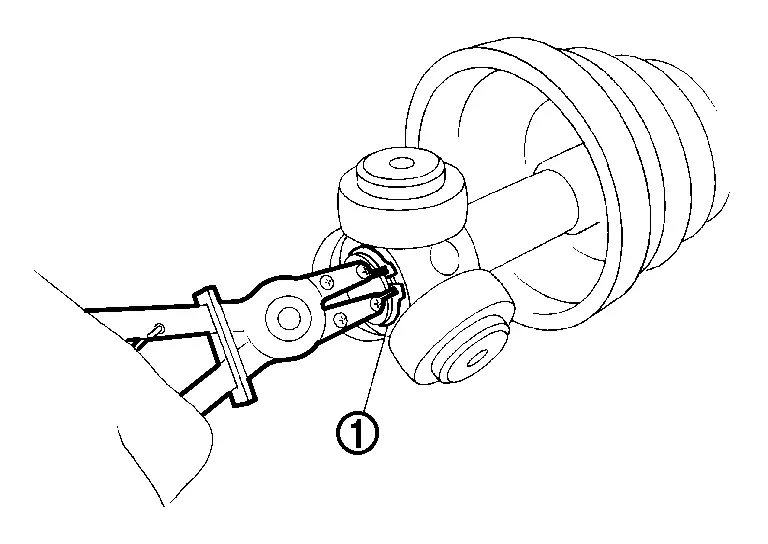

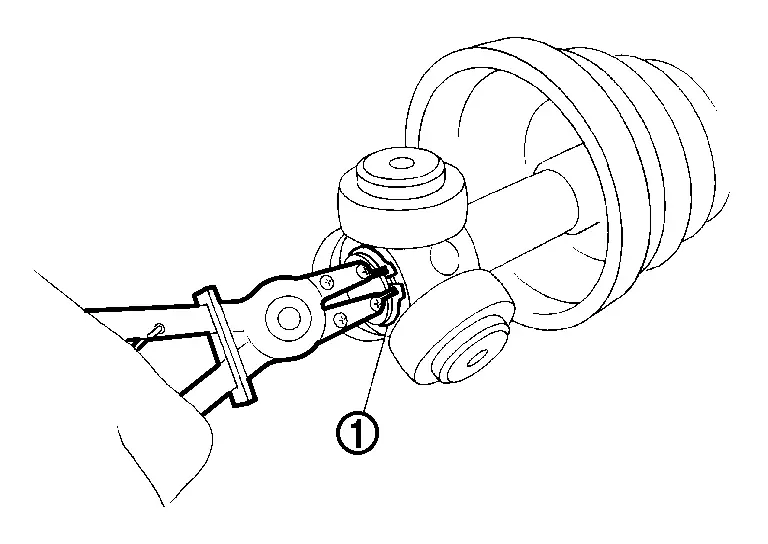

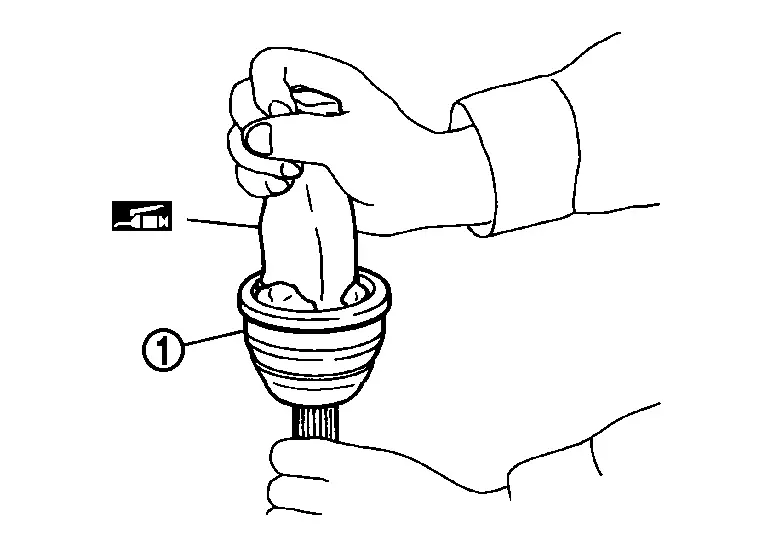

Remove snap ring (1), and then remove spider assembly from shaft.

Remove boot from shaft.

Remove circular clip housing.

Remove dust shield to housing.

Remove old grease on housing with paper towels.

Perform inspection after disassembly. Refer to Inspection.

Wheel Side

Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

Remove boot bands. Then remove boot from joint sub-assembly.

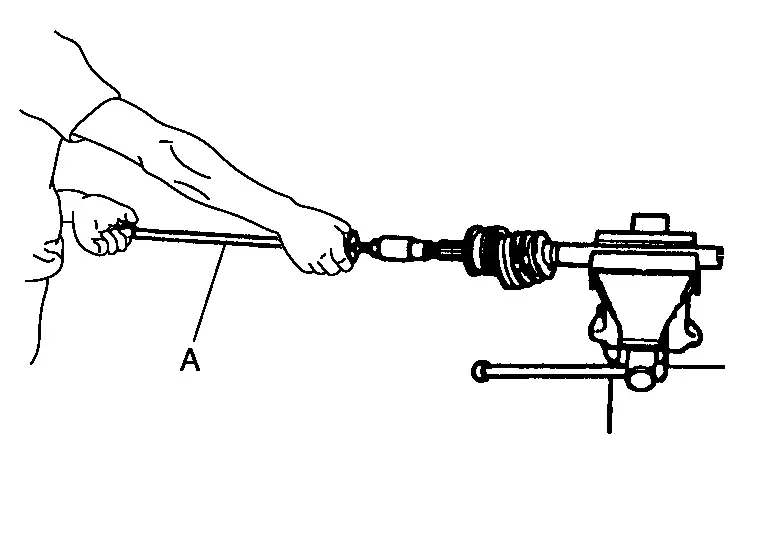

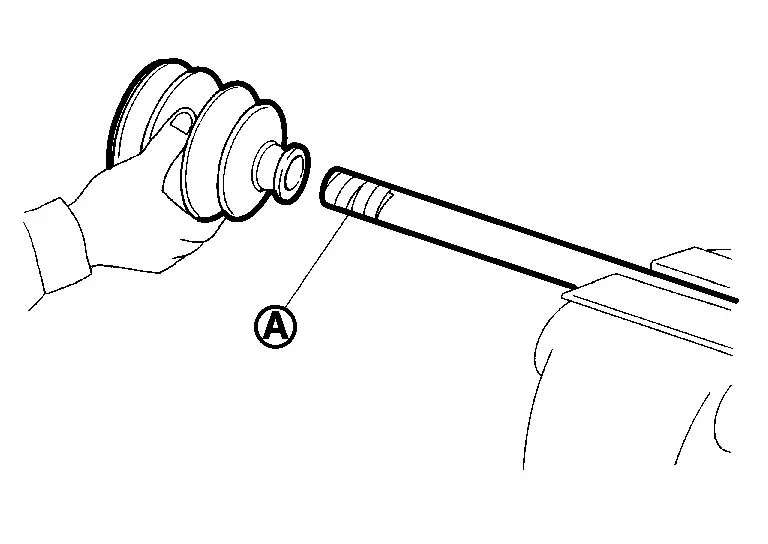

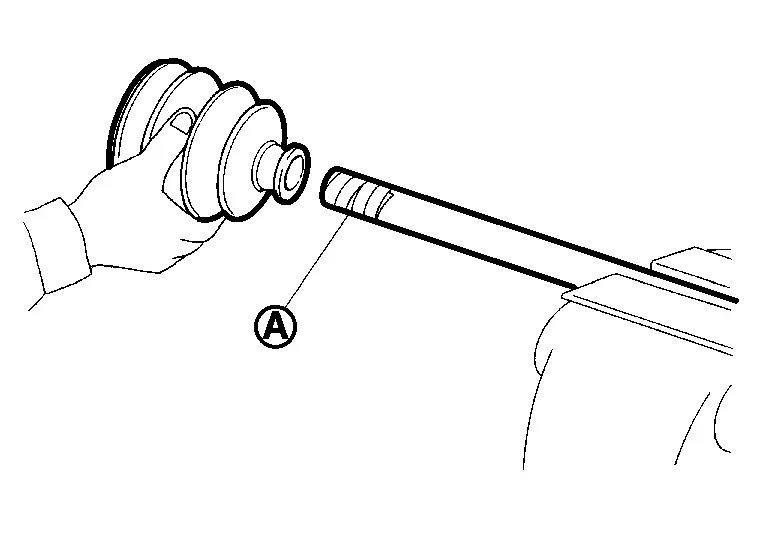

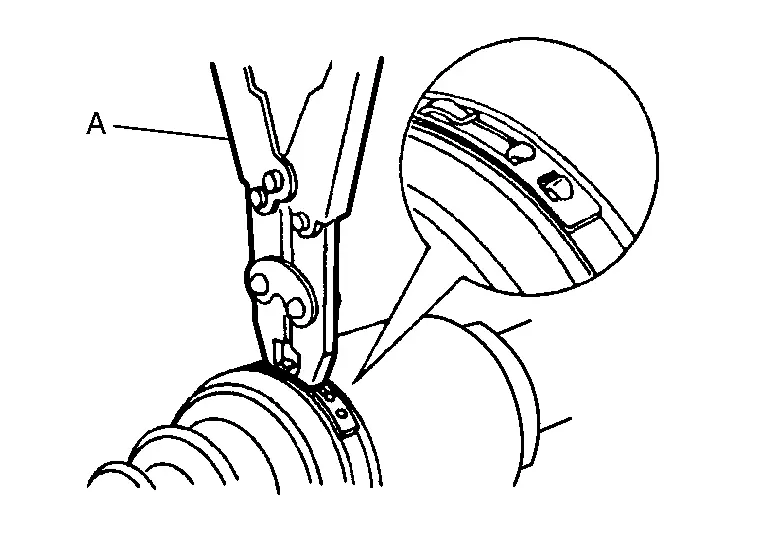

Screw drive shaft puller (A) (commercial service tool) into joint sub-assembly screw part to a length 30 mm (1.18 in) or more. Support drive shaft with one hand and pull out joint sub-assembly from shaft.

CAUTION:

-

If joint sub-assembly cannot be removed after five or more unsuccessful attempts, replace shaft and joint sub assembly as a set.

-

Align sliding hammer and drive shaft and remove them by pulling directory.

Remove circular clip from shaft.

CAUTION:

Never reuse circular clip.

Remove boot from shaft.

Remove old grease on joint sub-assembly with paper towels.

Perform inspection after disassembly. Refer to Inspection.

ASSEMBLY

Final drive Side

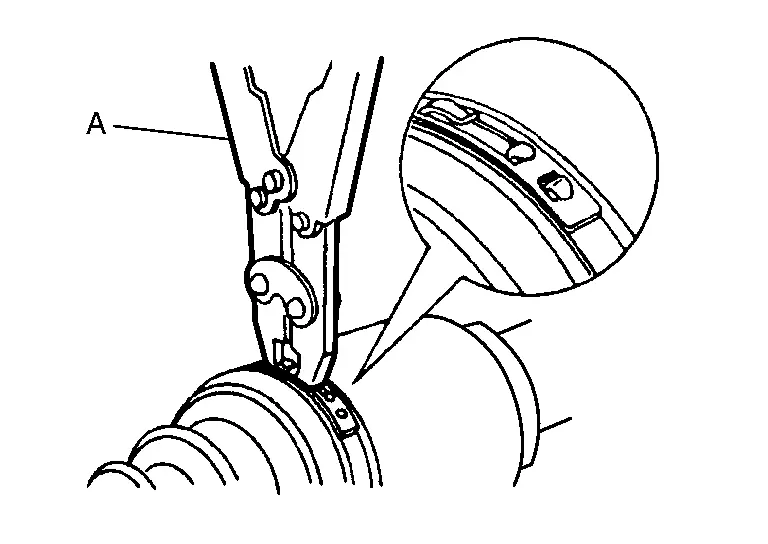

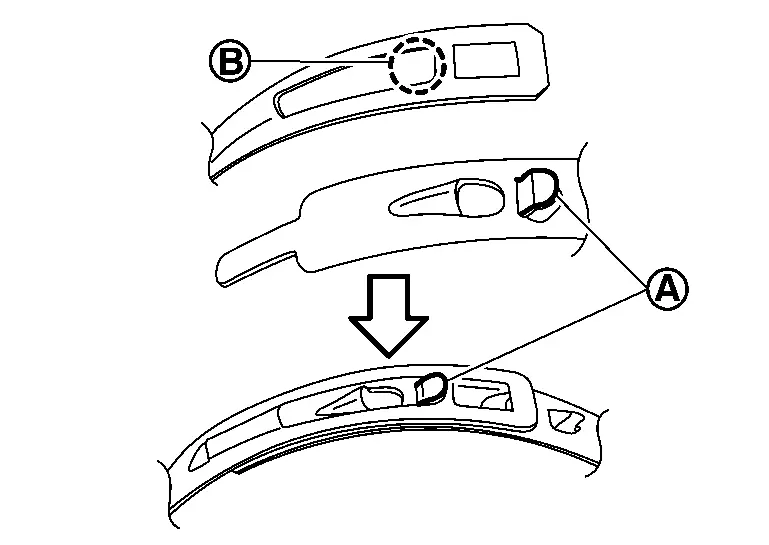

Wrap serration on shaft with tape (A) to protect boot from damage. Install new boot and boot band to shaft.

CAUTION:

Never reuse boot and boot band.

Remove the tape wrapped around the serrated on shaft.

To install the spider assembly (1), align it with the matching marks (A) on the shaft (2) during the removal, and direct the serration mounting surface (B) to the shaft.

Secure spider assembly onto shaft with snap ring (1).

CAUTION:

Never reuse snap ring.

Assemble the housing onto spider assembly, and apply the balance of the specified amount grease.

| Standard | |

| Grease amount | : Refer to Drive Shaft. |

Align matching marks painted when housing were removed.

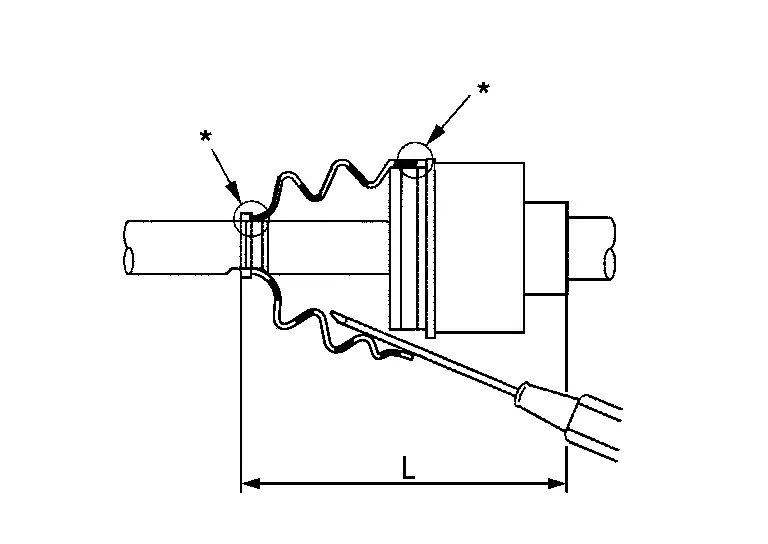

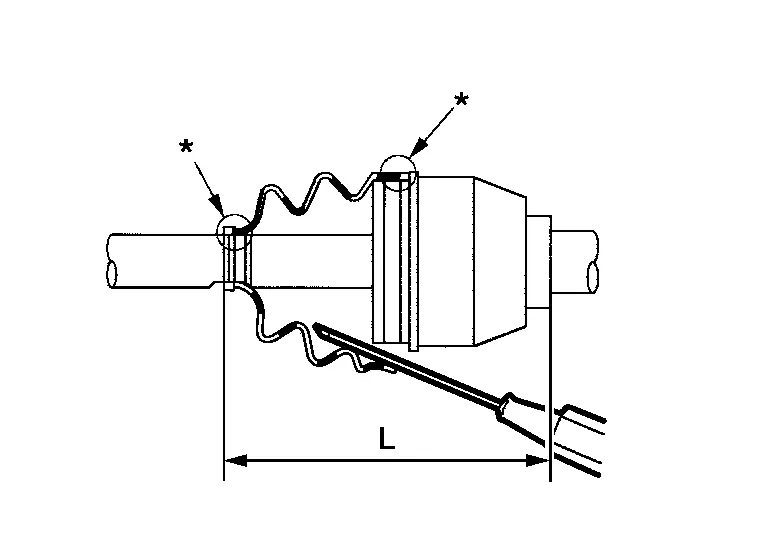

Install boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by “*” marks) of shaft or housing, boot may be removed. Remove all grease from the surfaces.

To prevent from deformation of the boot, adjust the boot installation length to the value shown below (L) by inserting the suitable tool into the inside of boot from the large diameter side of boot and discharging inside air.

| Standard | |

| L | : Refer to Drive Shaft. |

CAUTION:

-

If the boot installation length exceeds the standard, it may cause breakage in boot.

-

Be careful not to touch the inside of the boot with the tip of tool.

Install new boot bands securely.

CAUTION:

Never reuse boot band.

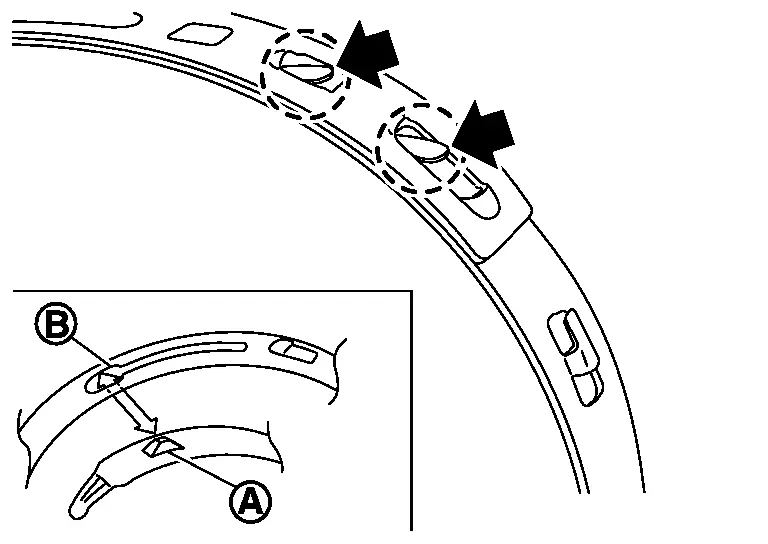

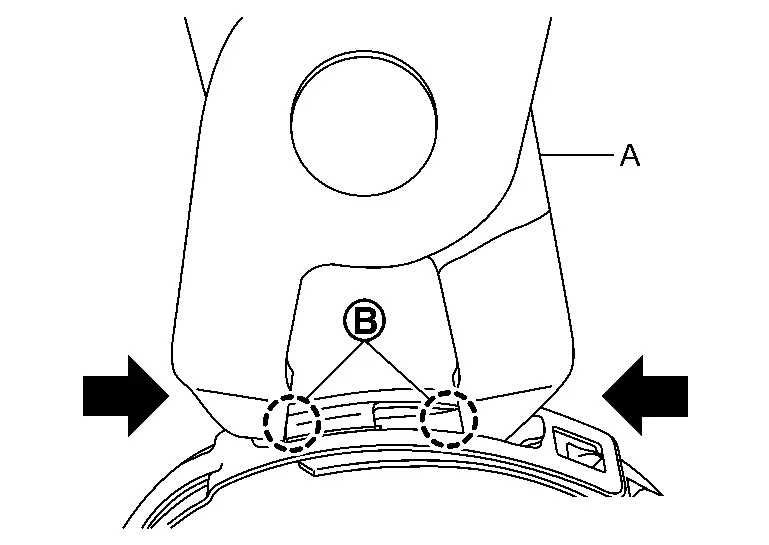

For low profile type band-

Put boot band in the groove on drive shaft boot. Then fit pawls (

) into holes to temporary installation.

) into holes to temporary installation.

NOTE:

NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at first.

-

Pinch projection on the band with suitable pliers to tighten band.

-

Insert tip of band below end of the pawl.

-

Secure the boot bands using the boot band crimping tool (A) (SST: KV40107300).

CAUTION:

Never reuse boot band.

NOTE:

NOTE:

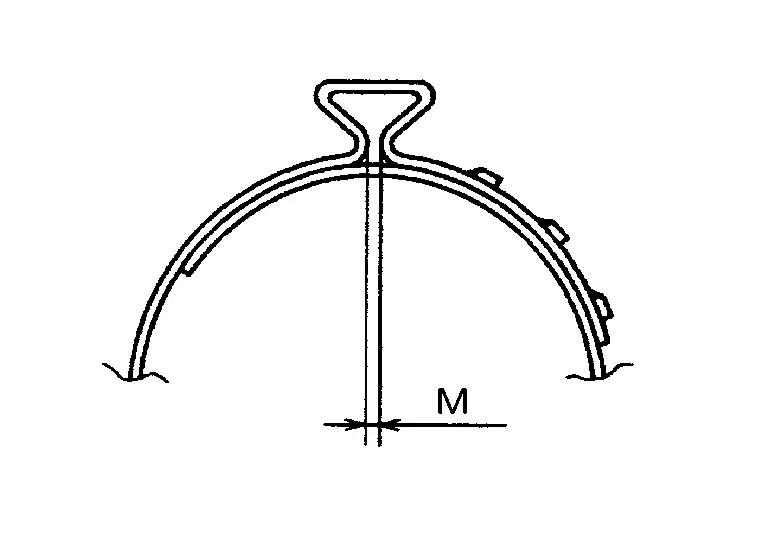

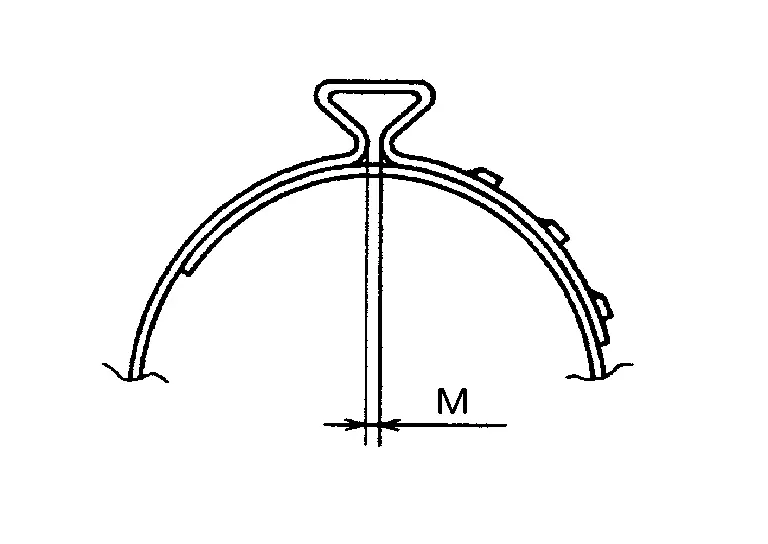

Secure boot band so that dimension (M) meets the specification as shown in the figure.

M : 1.0 - 4.0 mm (0.04 - 0.16)

Secure housing and shaft, and then make sure that they are in the correct position when rotating boot. Install them with new boot band when the mounting positions become incorrect.

Install dust shield to housing.

CAUTION:

Never reuse dust shield.

Install circular clip to housing.

CAUTION:

Never reuse circular clip.

Perform inspection after assembly. Refer to Inspection.

Wheel Side

Fill serration slot joint sub-assembly (1) with NISSAN genuine grease or equivalent until the serration slot and ball groove become full to the brim.

CAUTION:

After applying grease, use a shop cloth to wipe off old grease that has oozed out.

Wrap serrated part of shaft with tape (A). Install boot band and boot to shaft. Be careful not to damage boot.

CAUTION:

Never reuse boot and boot band.

Remove the tape wrapped around the serrated on shaft.

Position circular clip on groove at the shaft edge.

CAUTION:

Never reuse circular clip.

NOTE:

NOTE:

Drive joint inserter is recommended when installing circular clip.

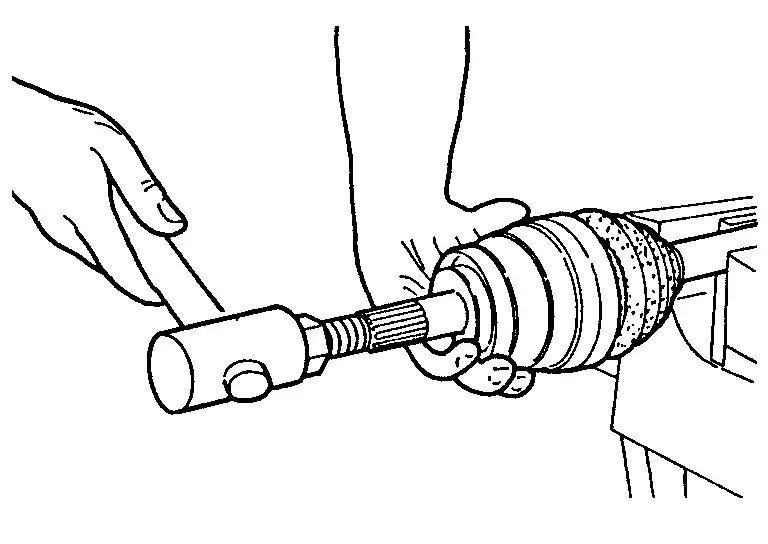

Align both center axles of the shaft edge and joint sub-assembly. Then assemble shaft with circular clip joint sub-assembly.

Install joint sub-assembly to shaft using plastic hammer.

CAUTION:

Confirm that joint sub-assembly is correctly engaged while rotating drive shaft.

Apply the balance of the specified amount of grease into the boot inside from large diameter side of boot.

| Standard | |

| Grease amount | : Refer to Drive Shaft. |

Install the boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (with “*” mark) on the shaft or joint sub-assembly, boot may be removed. Remove all grease from the surfaces.

To prevent from deformation of the boot, adjust the boot installation length to the specified value shown below (L) by inserting the suitable tool into inside of the boot from the large diameter side of boot and discharging the inside air.

| Standard | |

| L | : Refer to Drive Shaft. |

CAUTION:

-

If the boot installation length exceeds the standard, it may cause breakage in boot.

-

Be careful not to touch the inside of the boot with the tip of tool.

Secure large and small ends of boot with new boot bands as shown in the figure.

CAUTION:

Never reuse boot band.

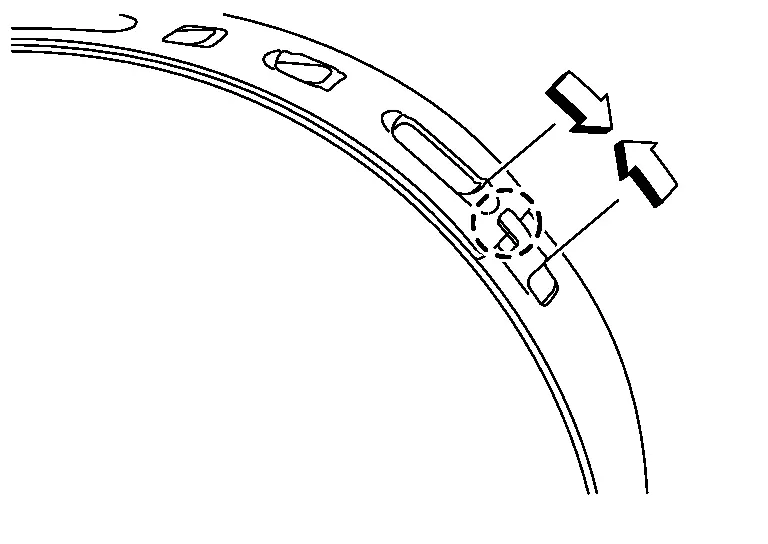

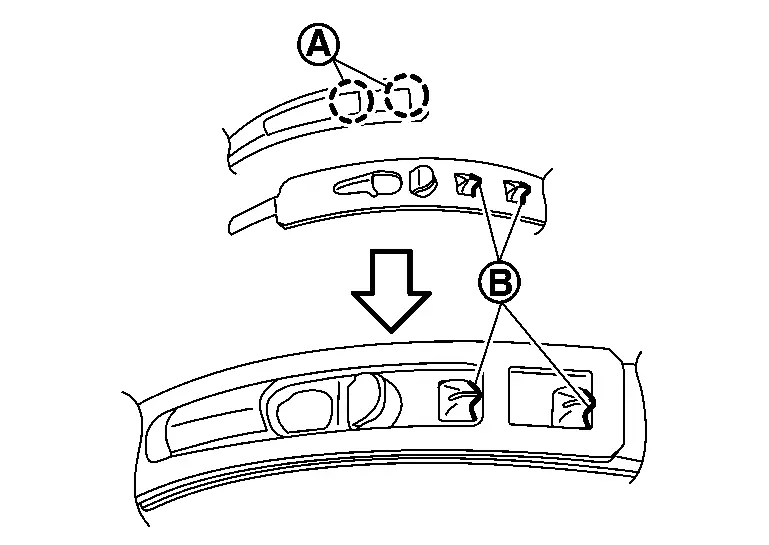

For low profile type band-

Set boot band to the drive shaft boot groove and temporarily fix pawl (A) of boot band to (B) of boot band.

-

Tighten boot band protrusions (B) with boot band crimping tool (SST: KV40107310) (A) in the direction shown by arrows (

).

).

CAUTION:

Securely install boot band (A) to boot band pawl (B).

-

Secure the boot bands using the boot band crimping tool (A) (SST: KV40107300).

CAUTION:

Never reuse boot band.

NOTE:

NOTE:

Secure boot band so that dimension (M) meets the specification as shown in the figure.

M : 2.3 mm (0.091 in) max

Secure housing and shaft, and then make sure that they are in the correct position when rotating boot. Install them with new boot band when the mounting positions become incorrect.

Inspection

INSPECTION AFTER REMOVAL

-

Move joint up/down, left/right, and in the axial direction. Check for motion that is not smooth and for significant looseness.

-

Check boot for cracks or other damage, and also for grease leakage.

-

If a malfunction is found, disassemble drive shaft, and then replace with new one.

INSPECTION AFTER DISASSEMBLY

Shaft

Check shaft for runout, cracks, or other damage. Replace if there are any abnormal condition.

Joint Sub-Assembly (Wheel Side)

Check the following:

-

Joint sub-assembly for rough rotation and excessive axial looseness.

-

The inside of the joint sub-assembly for entry of foreign material.

-

Joint sub-assembly for compression scars, cracks, and fractures inside of joint sub-assembly.

Replace joint sub-assembly if there are any non-standard conditions of components.

Housing and Spider assembly (Final Drive Side)

Replace housing and spider assembly if there is scratching or wear of housing roller contact surface or spider roller contact surface.

NOTE:

NOTE:

Housing and spider assembly are used in a set.

INSPECTION AFTER INSTALLATION

Check wheel sensor harness for proper connection. Refer to Exploded View.

If pressing the piston of rear brake caliper assembly, perform "REMOVAL/REPLACEMENT OF REAR BRAKE PAD OR REAR BRAKE CALIPER". Refer to Description.

Check wheel alignment. Refer to Inspection.

Adjust neutral position of steering angle sensor. Refer to Description.

Nissan Pathfinder (R53) 2022-2026 Service Manual

Contact Us

Nissan Pathfinder Info Center

Email: info@nipathfinder.com

Phone: +1 (800) 123-4567

Address: 123 Pathfinder Blvd, Nashville, TN 37214, USA

Working Hours: Mon–Fri, 9:00 AM – 5:00 PM (EST)