Nissan Pathfinder: Starting System - Diagnosis and Repair Work Flow

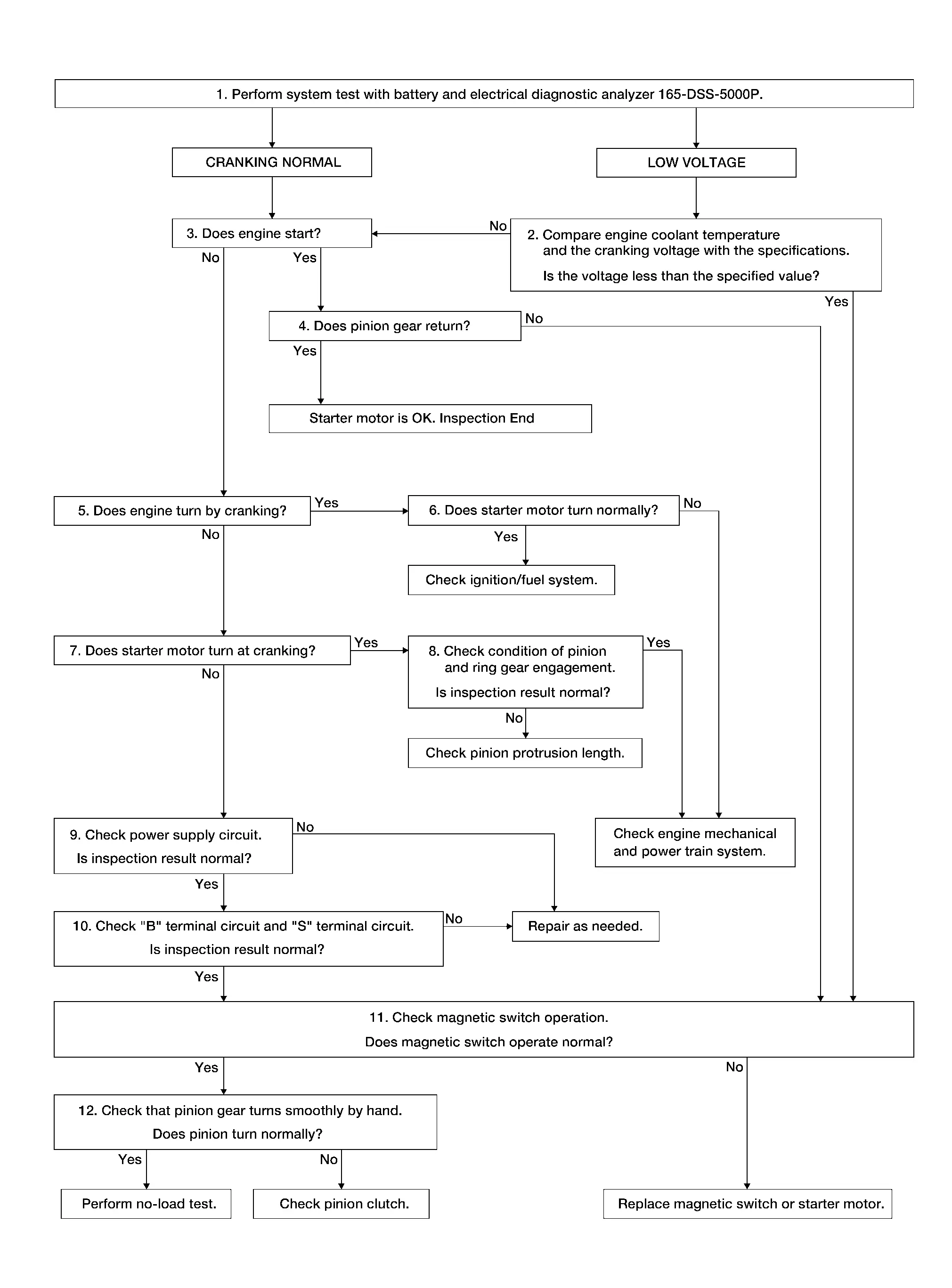

Work Flow (With 165-DSS-5000P)

STARTING SYSTEM DIAGNOSIS WITH 165-DSS-5000P

To test the starting system, use the following special service tool:

-

Battery and electrical diagnostic analyzer 165-DSS-5000P.

NOTE:

NOTE:

Refer to the diagnostic analyzer instruction manual for proper starting system diagnosis procedures.

OVERALL SEQUENCE

DETAILED FLOW

NOTE:

NOTE:

-

To ensure a complete and thorough diagnosis, the battery, starter motor and generator test segments must be done as a set from start to finish.

-

If any malfunction is found, immediately disconnect the battery cable from the negative terminal.

DIAGNOSIS WITH BATTERY AND ELECTRICAL DIAGNOSTIC ANALYZER 165-DSS-5000P

Perform system test with battery and electrical diagnostic analyzer 165-DSS-5000P. For details and operating instructions, refer to diagnostic analyzer instruction manual.

How is the test result?

CRANKING NORMAL>>GO TO 3.

LOW VOLTAGE>>GO TO 2.

CHARGE BATTERY>>Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Perform battery test again. Refer to diagnostic analyzer instruction manual.

REPLACE BATTERY>>Before replacing battery, clean the battery cable clamps and battery posts. Perform battery test again. Refer to diagnostic analyzer instruction manual. If second test result is “REPLACE BATTERY”, then do so. Perform battery test again to confirm repair.

COMPARISON BETWEEN ENGINE COOLANT AND CRANKING VOLTAGE

Compare engine coolant temperature and the cranking voltage with the specifications.

| Engine coolant temperature [°C (°F)] | Voltage [V] |

|---|---|

| −30 to −20 (−22 to −4) | 8.6 |

| −19 to −10 (−2 to 14) | 9.1 |

| −9 to 0 (16 to 32) | 9.5 |

| More than 1 (More than 34) | 9.9 |

Is the voltage less than the specified value?

YES>>GO TO 11.

NO>>GO TO 3.

CHECK ENGINE START

Crank engine and check that engine starts.

Does engine start?

YES>>GO TO 4.

NO>>GO TO 5.

CHECK RETURN OF PINION GEAR

Check that pinion gear returns to original position after engine starts.

Does pinion gear return?

YES>>Starter motor is OK. Inspection End.

NO>>GO TO 11.

CHECK ENGINE SPEED WITH CRANKING

Check that engine turns while cranking.

Does engine turns while cranking?

YES>>GO TO 6.

NO>>GO TO 7.

CHECK STARTER MOTOR TURNING WITH CRANKING

Check that starter motor runs smoothly without abnormal noise at cranking.

Does starter motor turn normally?

YES>>Check ignition/fuel system.

NO>>Check engine mechanical and power train system.

CHECK STARTER MOTOR SPEED WITH CRANKING

Check that starter motor turns while cranking.

Does starter motor turn at cranking?

YES>>GO TO 8.

NO>>GO TO 9.

CHECK PINION GEAR AND RING GEAR ENGAGEMENT

Check condition of pinion and ring gear engagement.

Is inspection result normal?

YES>>Check engine mechanical and power train system.

NO>>Check pinion protrusion length. Refer to Inspection and Adjustment.

CHECK POWER SUPPLY CIRCUIT

Check the following conditions:

-

Fuse and fusible link.

-

Charge condition, corrosion and connection condition of battery. Refer to How to Handle Battery.

Are these inspection result normal?

YES>>GO TO 10.

NO>>Repair as needed.

CHECK STARTING SYSTEM WIRING

Check the following:

-

“B” terminal circuit. Refer to Diagnosis Procedure.

-

“S” terminal circuit. Refer to Diagnosis Procedure.

Are these inspection results normal?

YES>>GO TO 11.

NO>>Repair as needed.

CHECK MAGNETIC SWITCH OPERATION

Check magnetic switch operation. Refer to Inspection and Adjustment.

Does magnetic switch operate normal?

YES>>GO TO 12.

NO>>Replace magnetic switch or starter motor.

CHECK PINION TURNING

-

Remove starter motor.

-

Check that pinion turns smoothly by hand.

Does pinion turn normally?

YES>>Perform no-load test of starter motor. Refer to Inspection and Adjustment.

NO>>Check pinion clutch. Refer to Inspection and Adjustment.

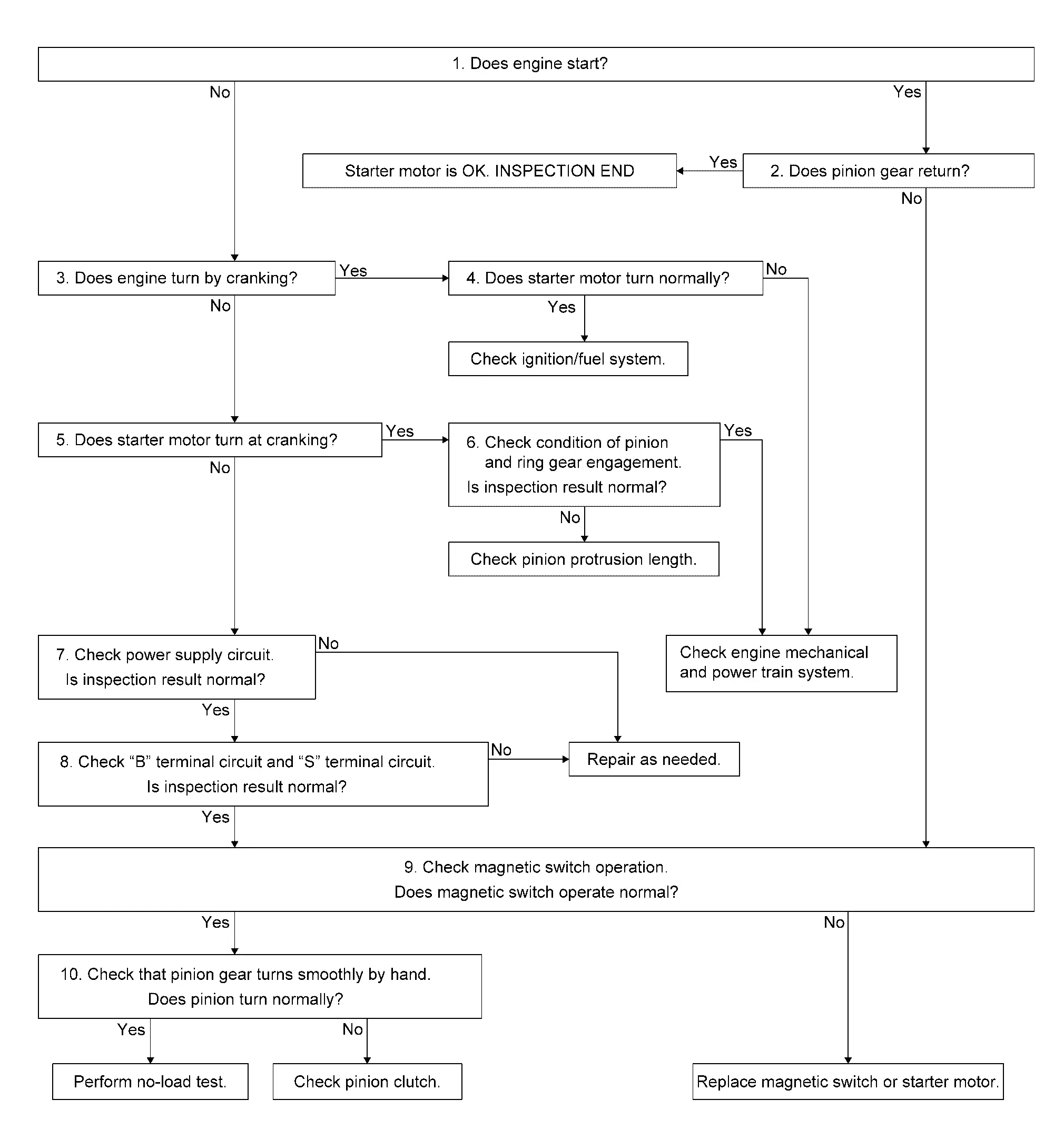

Work Flow (Without 165-DSS-5000P)

OVERALL SEQUENCE

DETAILED FLOW

NOTE:

NOTE:

If any malfunction is found, immediately disconnect the battery cable from the negative terminal.

CHECK ENGINE START

Crank the engine and check that the engine starts.

Does the engine start?

YES>>GO TO 2.

NO>>GO TO 3.

CHECK RETURN OF PINION GEAR

Check that pinion gear returns to original position after engine starts.

Does pinion gear return?

YES>>Starter motor is OK. Inspection End.

NO>>GO TO 9.

CHECK ENGINE SPEED WITH CRANKING

Check that engine turns while cranking.

Does engine turn by cranking?

YES>>GO TO 4.

NO>>GO TO 5.

CHECK STARTER MOTOR TURNING WITH CRANKING

Check that starter motor runs smoothly without abnormal noise at cranking.

Does starter motor turn normally?

YES>>Check ignition/fuel system.

NO>>Check engine mechanical and power train system.

CHECK STARTER MOTOR SPEED WITH CRANKING

Check that starter motor turns while cranking.

Does starter motor turn at cranking?

YES>>GO TO 6.

NO>>GO TO 7.

CHECK PINION GEAR AND RING GEAR ENGAGEMENT

Check condition of pinion and ring gear engagement.

Is inspection result normal?

YES>>Check engine mechanical and power train system.

NO>>Check pinion protrusion length. Refer to Inspection and Adjustment.

CHECK POWER SUPPLY CIRCUIT

Check the following conditions:

-

Fuse and fusible link.

-

Charge condition, corrosion and connection condition of battery. Refer to How to Handle Battery.

Are the inspection results normal?

YES>>GO TO 8.

NO>>Repair as needed.

CHECK STARTING SYSTEM WIRING

Check the following:

-

“B” terminal circuit. Refer to Diagnosis Procedure.

-

“S” terminal circuit. Refer to Diagnosis Procedure.

Are the inspection results normal?

YES>>GO TO 9.

NO>>Repair as needed.

CHECK MAGNETIC SWITCH OPERATION

Check magnetic switch operation. Refer to Inspection and Adjustment.

Does magnetic switch operate normal?

YES>>GO TO 10.

NO>>Replace magnetic switch or starter motor.

CHECK PINION TURNING

-

Remove starter motor.

-

Check that pinon turns smoothly by hand.

Does pinion turn normally?

YES>>Perform no-load test of starter motor. Refer to Inspection and Adjustment.

NO>>Check pinion clutch. Refer to Inspection and Adjustment.

Nissan Pathfinder (R53) 2022-2026 Service Manual

Contact Us

Nissan Pathfinder Info Center

Email: info@nipathfinder.com

Phone: +1 (800) 123-4567

Address: 123 Pathfinder Blvd, Nashville, TN 37214, USA

Working Hours: Mon–Fri, 9:00 AM – 5:00 PM (EST)