Nissan Pathfinder: Heater & Air Conditioning System - Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collisions.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” sections of this Service Manual.

WARNING:

Always observe the following items for preventing accidental activation:

-

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision that would result in air bag inflation, it is recommended that all maintenance and repair be performed by an authorized NISSAN/INFINITI dealer.

-

Improper repair, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see “SRS AIR BAG”.

-

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

Always observe the following items for preventing accidental activation:

-

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition/power switch ON or engine running, never use air or electric power tools or strike near the sensor(s) with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing serious injury.

-

When using air or electric power tools or hammers, always switch the ignition/power switch OFF, disconnect the 12V battery or batteries, and wait at least 3 minutes before performing any service.

Precautions for Work

-

When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

-

When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

-

Protect the removed parts with a shop cloth and prevent them from being dropped.

-

Replace a deformed or damaged clip.

-

If a part is specified as a non-reusable part, always replace it with a new one.

-

Be sure to tighten bolts and nuts securely to the specified torque.

-

After installation is complete, be sure to check that each part works properly.

-

Follow the steps below to clean components:

-

Water soluble dirt:

-

Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

-

Then rub with a soft, dry cloth.

-

-

Oily dirt:

-

Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

-

Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

-

Then rub with a soft, dry cloth.

-

-

Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

-

For genuine leather seats, use a genuine leather seat cleaner.

-

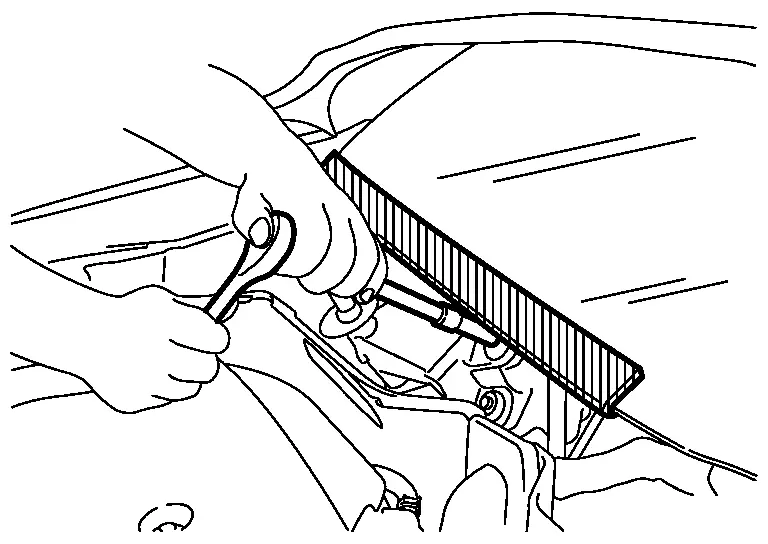

Precaution for Procedure without Cowl Top Cover

When performing the procedure after removing cowl top cover, cover the lower end of windshield with urethane, etc to prevent damage to windshield.

Precautions For Refrigerant System Service

GENERAL REFRIGERANT PRECAUTION

WARNING:

-

Do not breathe A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat. Remove HFO-1234yf (R-1234yf) from the A/C system, using certified service equipment meeting requirements of SAE NI-2210 [HFO-1234yf (R-1234yf) recycling equipment] or NI-2209 [HFO-1234yf (R-1234yf) recovery equipment]. Ventilate work area before resuming service if accidental system discharge occurs. Additional health and safety information may be obtained from refrigerant and oil manufacturers.

-

Do not release refrigerant into the air. Use approved recovery/recycling recharging equipment to capture the refrigerant each time an air conditioning system is discharged.

-

Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air conditioning system.

-

Do not store or heat refrigerant containers above 52°C (126°F).

-

Do not heat a refrigerant container with an open flame; Place the bottom of the container in a warm pail of water if container warming is required.

-

Do not intentionally drop, puncture or incinerate refrigerant containers.

-

Keep refrigerant away from open flames; poisonous gas is produced if refrigerant burns.

-

Refrigerant displaces oxygen; therefore be certain to work in well ventilated areas to prevent suffocation.

-

Do not pressure test or leak test HFO-1234yf (R-1234yf) service equipment and/or Nissan Pathfinder vehicle air conditioning systems with compressed air during repair. Some mixtures of air and HFO-1234yf (R-1234yf) have been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or property damage. Additional health and safety information may be obtained from refrigerant manufacturers.

WORKING WITH HFO-1234yf (R-1234yf)

CAUTION:

-

CFC-12 or HFC-134a (R-134a) refrigerant and HFO-1234yf (R-1234yf) refrigerant are not compatible. Compressor malfunction is likely to occur if the refrigerants are mixed, refer to “CONTAMINATED REFRIGERANT” below. To determine the purity of HFO-1234yf (R-1234yf) in the Nissan Pathfinder vehicle and recovery tank, use Refrigerant recovery/recycling recharging equipment and Refrigerant Identifier.

-

Use only specified oil for the HFO-1234yf (R-1234yf) A/C system and HFO-1234yf (R-1234yf) components. Compressor malfunction is likely to occur if oil other than that specified is used.

-

The specified HFO-1234yf (R-1234yf) oil rapidly absorbs moisture from the atmosphere. The following handling precautions must be observed:

-

Cap (seal) the component immediately to minimize the entry of moisture from the atmosphere when removing refrigerant components from a Nissan Pathfinder vehicle.

-

Do not remove the caps (unseal) until just before connecting the components when installing refrigerant components to a Nissan Pathfinder vehicle. Connect all refrigerant loop components as quickly as possible to minimize the entry of moisture into system.

-

Use only the specified oil from a sealed container. Reseal containers of oil immediately. Oil becomes moisture saturated and should not be used without proper sealing.

-

Do not allow oil to come in contact with styrene foam parts. Damage may result.

-

CONTAMINATED REFRIGERANT

Take appropriate steps shown below if a refrigerant other than pure HFO-1234yf (R-1234yf) is identified in a Nissan Pathfinder vehicle:

-

Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into the atmosphere.

-

Explain that recovery of the contaminated refrigerant could damage service equipment and refrigerant supply.

-

Suggest the customer return the Nissan Pathfinder vehicle to the location of previous service where the contamination may have occurred.

-

In case of repairing, recover the refrigerant using only dedicated equipment and containers. Do not recover contaminated refrigerant into the existing service equipment. Contact a local refrigerant product retailer for available service if the facility does not have dedicated recovery equipment. This refrigerant must be disposed of in accordance with all federal and local regulations. In addition, replacement of all refrigerant system components on the Nissan Pathfinder vehicle is recommended.

-

The air conditioner warranty is void if the vehicle is within the warranty period. Please contact NISSAN Customer Affairs for further assistance.

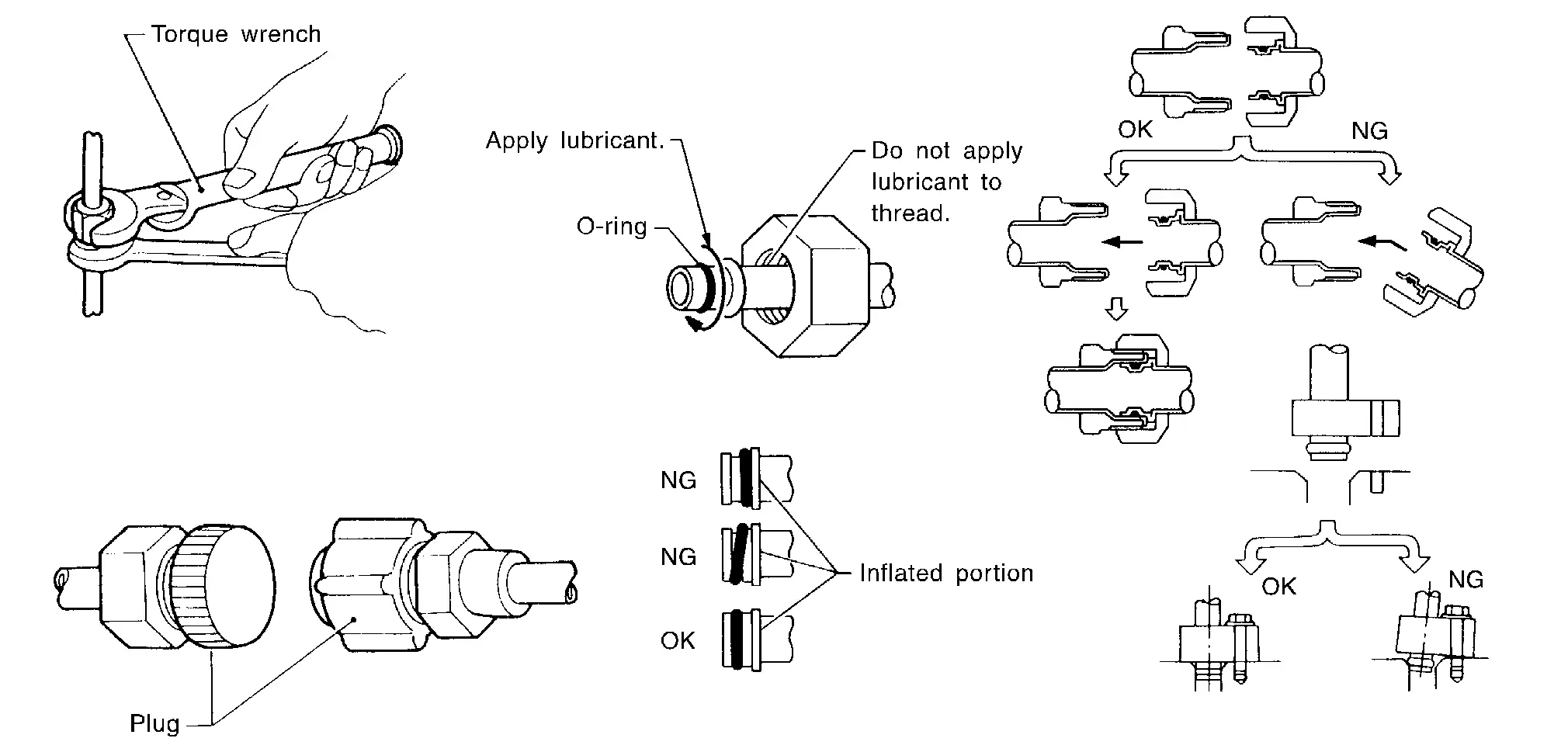

REFRIGERANT CONNECTION

A new type of refrigerant connection has been introduced to all refrigerant lines except the following locations:

-

Expansion valve to evaporator

-

Refrigerant pressure sensor to liquid tank

WARNING:

Check that all refrigerant is discharged into the recycling equipment and the pressure in the system is less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

Observe the following when replacing or cleaning refrigerant components.

-

When the compressor is removed, store it in the same way as it is when mounted on the Nissan Pathfinder vehicle. Failure to do so will cause oil to enter the low-pressure chamber.

-

Always use a torque wrench and a back-up wrench when connecting tubes.

-

Plug immediately all openings to prevent entry of dust and moisture after disconnecting tubes.

-

Connect the pipes at the final stage of the operation when installing an air conditioner in the Nissan Pathfinder vehicle. Do not remove the seal caps of pipes and other components until just before required for connection.

-

Allow components stored in cool areas to warm to working area temperature before removing seal caps. This prevents condensation from forming inside A/C components.

-

Remove moisture thoroughly from the refrigeration system before charging the refrigerant.

-

Always replace used O-rings.

-

Apply oil to the O-rings shown in illustrations when connecting tubes. Be careful not to apply oil to threaded portion.

-

O-ring must be closely attached to the groove portion of tube.

-

Be careful not to damage O-ring and tube when replacing the O-ring.

-

Connect tube until a click can be heard. Then tighten the nut or bolt by hand. Check that the O-ring is installed to tube correctly.

-

Perform leak test and make sure that there are no leaks from connections after connecting line. Disconnect that line and replace the O-ring when the refrigerant leaking point is found. Then tighten connections of seal seat to the specified torque.

COMPRESSOR

CAUTION:

-

Plug all openings to prevent moisture and foreign matter from entering.

-

When the compressor is removed, store it in the same way as it is when mounted on the Nissan Pathfinder vehicle.

-

Follow “Oil Adjusting Procedure for Compressor Replacement" exactly when replacing or repairing compressor. Refer to Oil Adjusting Procedure for Compressor Replacement.

-

Keep friction surfaces between clutch and pulley clean. Wipe them off by using a clean waste cloth moistened with solvent if the surface is contaminated with oil.

-

Turn the compressor shaft by hand more than five turns in both directions after compressor service operation. This distributes oil equally inside the compressor. Let the engine idle and operate the compressor for one hour after the compressor is installed.

-

After replacing the compressor magnet clutch, apply voltage to the new one and check for normal operation.

LEAK DETECTION DYE

CAUTION:

-

The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet (UV) lamp is required to illuminate the dye when inspecting for leaks.

-

Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of the fluorescent dye.

-

A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should only be repaired after confirming the leak with an electronic refrigerant leak detector (NI-41995).

-

Always remove any dye from the leak area after repairs are complete to avoid a misdiagnosis during a future service.

-

Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled, clean immediately with the approved dye cleaner. Fluorescent dye left on a surface for an extended period of time cannot be removed.

-

Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

-

Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

-

Leak detection dyes for HFO-1234yf (R-1234yf) and HFC-134a (R-134a) A/C systems are different. Do not use HFO-1234yf (R-1234yf) leak detection dye in R-12 A/C systems or CFC-12 (R-12) leak detection dye in HFO-1234yf (R-1234yf) A/C systems or A/C system damage may result.

-

The fluorescent properties of the dye will remain for over three (3) years unless a compressor failure occurs.

NOTE:

NOTE:

Identification

-

Vehicles with factory installed fluorescent dye have a green label.

-

Nissan Pathfinder Vehicles without factory installed fluorescent dye have a blue label.

Service Equipment

RECOVERY/RECYCLING EQUIPMENT

Follow the manufacturer's instructions for machine operation and machine maintenance. Do not introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Follow the manufacturer's instructions for tester operation and tester maintenance.

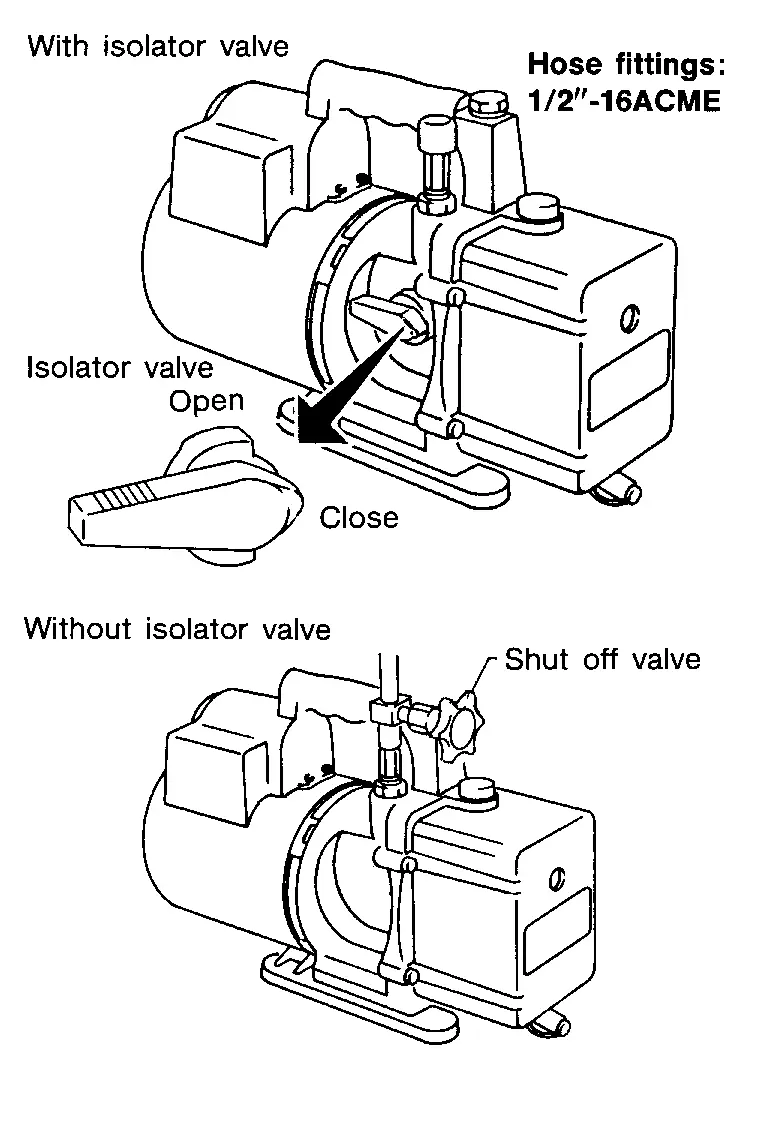

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the specified oil for HFO-1234yf (R-1234yf) A/C systems. The vent side of the vacuum pump is exposed to atmospheric pressure so the vacuum pump oil may migrate out of the pump into the service hose. This is possible when the pump is switched off after evacuation (vacuuming) and hose is connected to it.

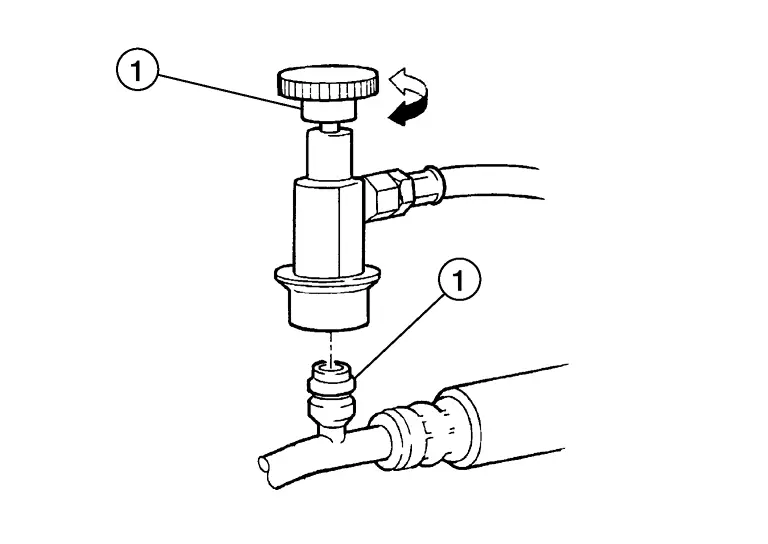

To prevent this migration, use a manual valve situated near the hose-to-pump connection, as follows.

-

Usually vacuum pumps have a manual isolator valve as part of the pump. Close this valve to isolate the service hose from the pump.

-

For pumps without an isolator, use a hose equipped with a manual shut-off valve near the pump end. Close the valve to isolate the hose from the pump.

-

If the hose has an automatic shut off valve, disconnect the hose from the pump: as long as the hose is connected, the valve is open and oil may migrate.

Some one-way valves open when vacuum is applied and close under a no vacuum condition. Such valves may restrict the pump's ability to pull a deep vacuum and are not recommended.

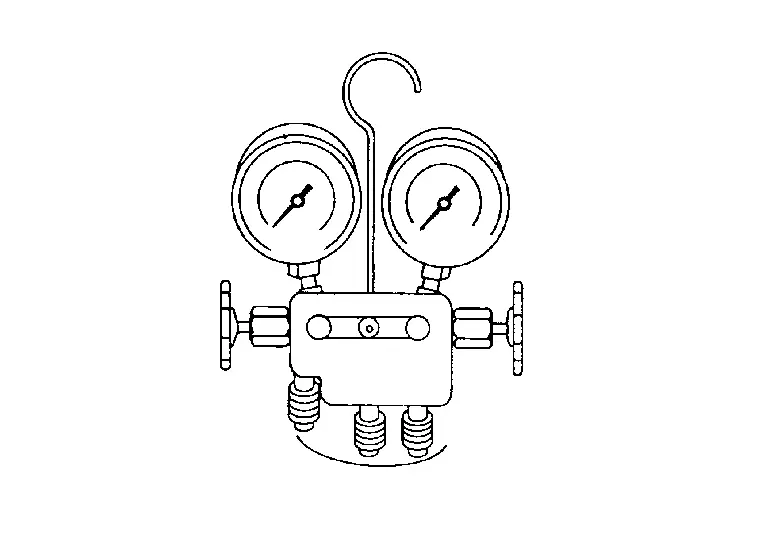

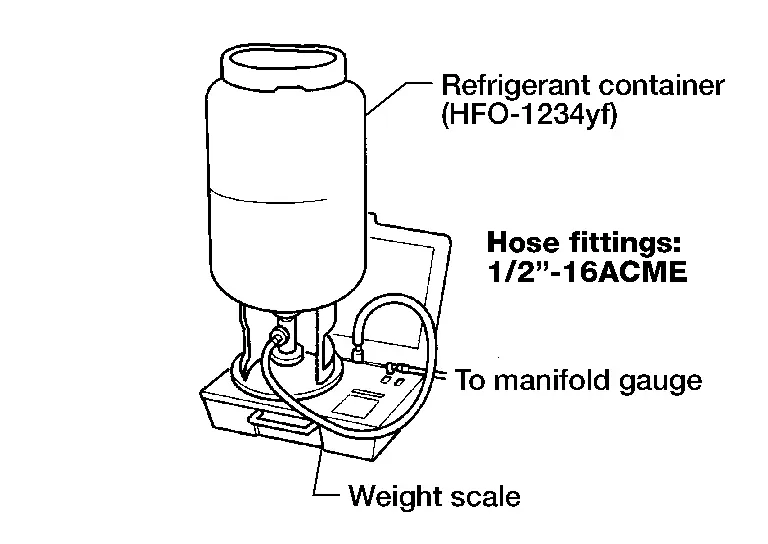

MANIFOLD GAUGE SET

Be certain that the gauge face indicates R-1234yf or 1234yf. Make sure the gauge set has 1/2″-16 LH ACME threaded connections for service hoses. Confirm the set has been used only with refrigerant HFO-1234yf (R-1234yf) along with specified oil.

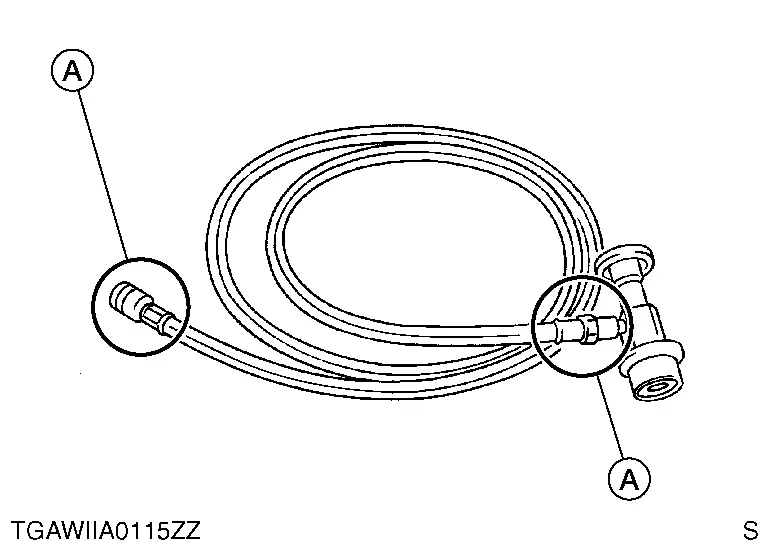

SERVICE HOSES

Be certain that the service hoses display the markings described (colored hose with black stripe). All hoses must include positive shut- off devices (either manual or automatic) near the end of the hoses opposite the manifold gauge.

SERVICE COUPLERS

Do not attempt to connect HFO-1234yf (R-1234yf) service couplers to the CFC-12 (R-12) and HFC-134a (R-134a) A/C systems. The HFO-1234yf (R-1234yf) couplers do not properly connect to the CFC-12 (R-12) and HFC-134a (R-134a) systems. However, if an improper connection is attempted, discharging and contamination may occur.

| Shut-off valve rotation | A/C service valve |

| Clockwise | Open |

| Counterclockwise | Close |

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFO-1234yf (R-1234yf) and specified oils have been used with the scale. If the scale controls refrigerant flow electronically, the hose fitting must be 1/2”-16 LH ACME.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder's top valve when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an electronic scale or of quality recycle/recharge equipment.

Nissan Pathfinder (R53) 2022-2026 Service Manual

Contact Us

Nissan Pathfinder Info Center

Email: info@nipathfinder.com

Phone: +1 (800) 123-4567

Address: 123 Pathfinder Blvd, Nashville, TN 37214, USA

Working Hours: Mon–Fri, 9:00 AM – 5:00 PM (EST)