Nissan Pathfinder: Charging System - Diagnosis and Repair Work Flow

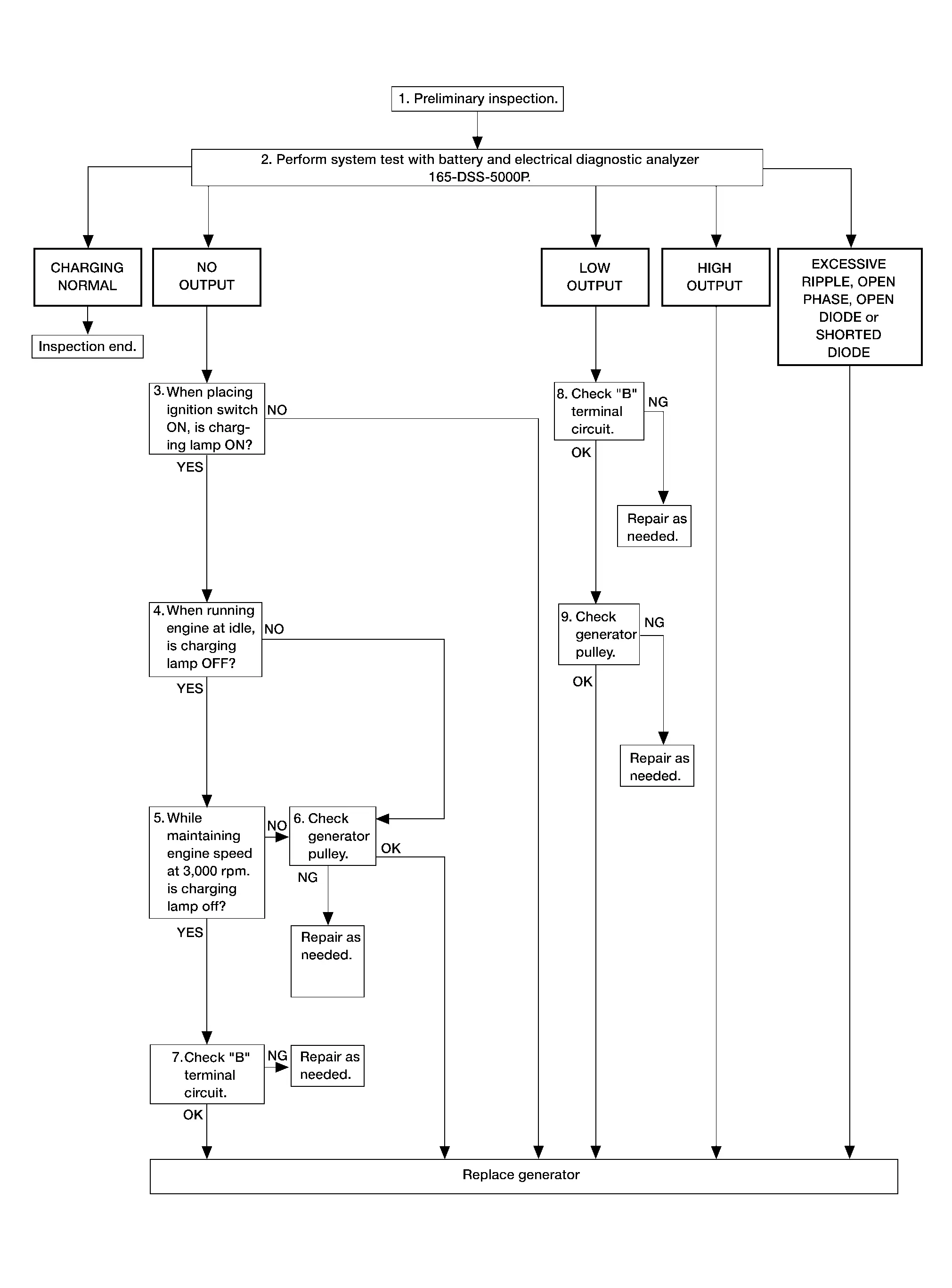

Work Flow (With 165-DSS-5000P)

CHARGING SYSTEM DIAGNOSIS WITH 165-DSS-5000P

To test the charging system, use the following special service tool:

-

165-DSS-5000P battery and electrical diagnostic analyzer

NOTE:

NOTE:

Refer to the applicable Instruction manual for proper charging system diagnosis procedures.

OVERALL SEQUENCE

DETAILED FLOW

NOTE:

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter motor and generator test segments must be done as a set from start to finish.

PRELIMINARY INSPECTION

Perform charging system preliminary inspection. Refer to Diagnosis Procedure.

>>

GO TO 2.

DIAGNOSIS WITH 165-DSS-5000P

Perform the system test using battery and electrical diagnostic analyzer 165-DSS-5000P. Refer to the applicable instruction manual for proper testing procedures.

Test result

CHARGING NORMAL>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO OUTPUT>>GO TO 3.

LOW OUTPUT>>GO TO 8.

HIGH OUTPUT>>Replace generator. Refer to Removal and Installation.

EXCESSIVE RIPPLE, OPEN PHASE, OPEN DIODE or SHORTED DIODE>>Replace generator. Refer to Removal and Installation. Perform system test again using the 165-DSS-5000P battery and electrical diagnostic analyzer to confirm repair.

INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Ignition switch ON.

Does the charge warning lamp illuminate?

YES>>GO TO 4.

NO>>Replace generator. Refer to Removal and Installation.

INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES>>GO TO 5.

NO>>GO TO 6.

INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 3,000 RPM)

Increase and maintain the engine speed at 3,000 rpm.

Does the charge warning lamp remain off?

YES>>GO TO 7.

NO>>GO TO 6.

INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to Inspection.

Is generator pulley normal?

YES>>Replace generator. Refer to Removal and Installation.

NO>>Repair as needed.

“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to Diagnosis Procedure.

Is “B” terminal circuit normal?

YES>>Replace generator. Refer to Removal and Installation.

NO>>Repair as needed.

“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to Diagnosis Procedure.

Is “B” terminal circuit normal?

YES>>GO TO 9.

NO>>Repair as needed.

INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to Inspection.

Is generator pulley normal?

YES>>Replace generator. Refer to Removal and Installation.

NO>>Repair as needed.

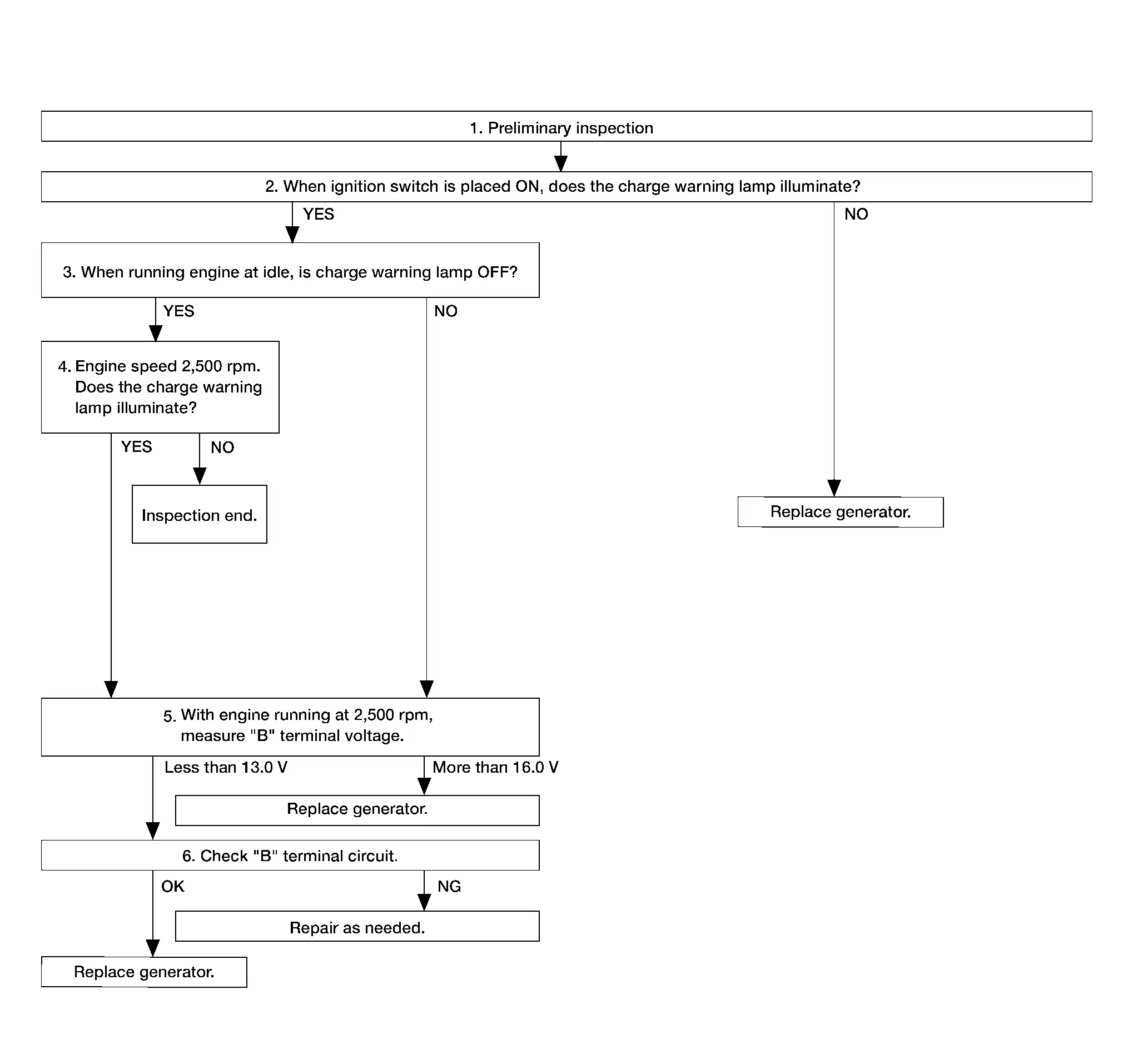

Work Flow (Without 165-DSS-5000P)

Before performing a generator test, make sure that the battery is fully charged. A 30-volt voltmeter and suitable test probes are necessary for the test.

-

Before starting, inspect the fusible link.

-

Use fully charged battery.

OVERALL SEQUENCE

DETAILED FLOW

PRELIMINARY INSPECTION

Perform the charging system preliminary inspection. Refer to Diagnosis Procedure.

>>

GO TO 2.

INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS PLACED ON)

When ignition switch is placed ON.

Does the charge warning lamp illuminate?

YES>>GO TO 3.

NO>>Replace generator. Refer to Removal and Installation.

INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES>>GO TO 4.

NO>>GO TO 5.

INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 2,500 RPM)

Increase and maintain the engine speed at 2,500 rpm.

Does the charge warning lamp illuminate?

YES>>GO TO 5.

NO>>Inspection End.

MEASURE “B” TERMINAL VOLTAGE

Start engine. With engine running at 2,500 rpm, measure “B” terminal voltage.

What voltage does the measurement result show?

Less than 13.0 V>>GO TO 6.

More than 16.0 V>>Replace generator. Refer to Removal and Installation.

“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>Replace generator. Refer to Removal and Installation.

NO>>Repair as needed.

Nissan Pathfinder (R53) 2022-2026 Service Manual

Contact Us

Nissan Pathfinder Info Center

Email: info@nipathfinder.com

Phone: +1 (800) 123-4567

Address: 123 Pathfinder Blvd, Nashville, TN 37214, USA

Working Hours: Mon–Fri, 9:00 AM – 5:00 PM (EST)