Nissan Pathfinder: Heater & Air Conditioning Control System - Basic Inspection

- Diagnosis and Repair Work Flow

- Operation Inspection

- Additional Service When Replacing Control Unit

- Configuration (hvac)

- System Setting

Diagnosis and Repair Work Flow Nissan Pathfinder 5th Gen

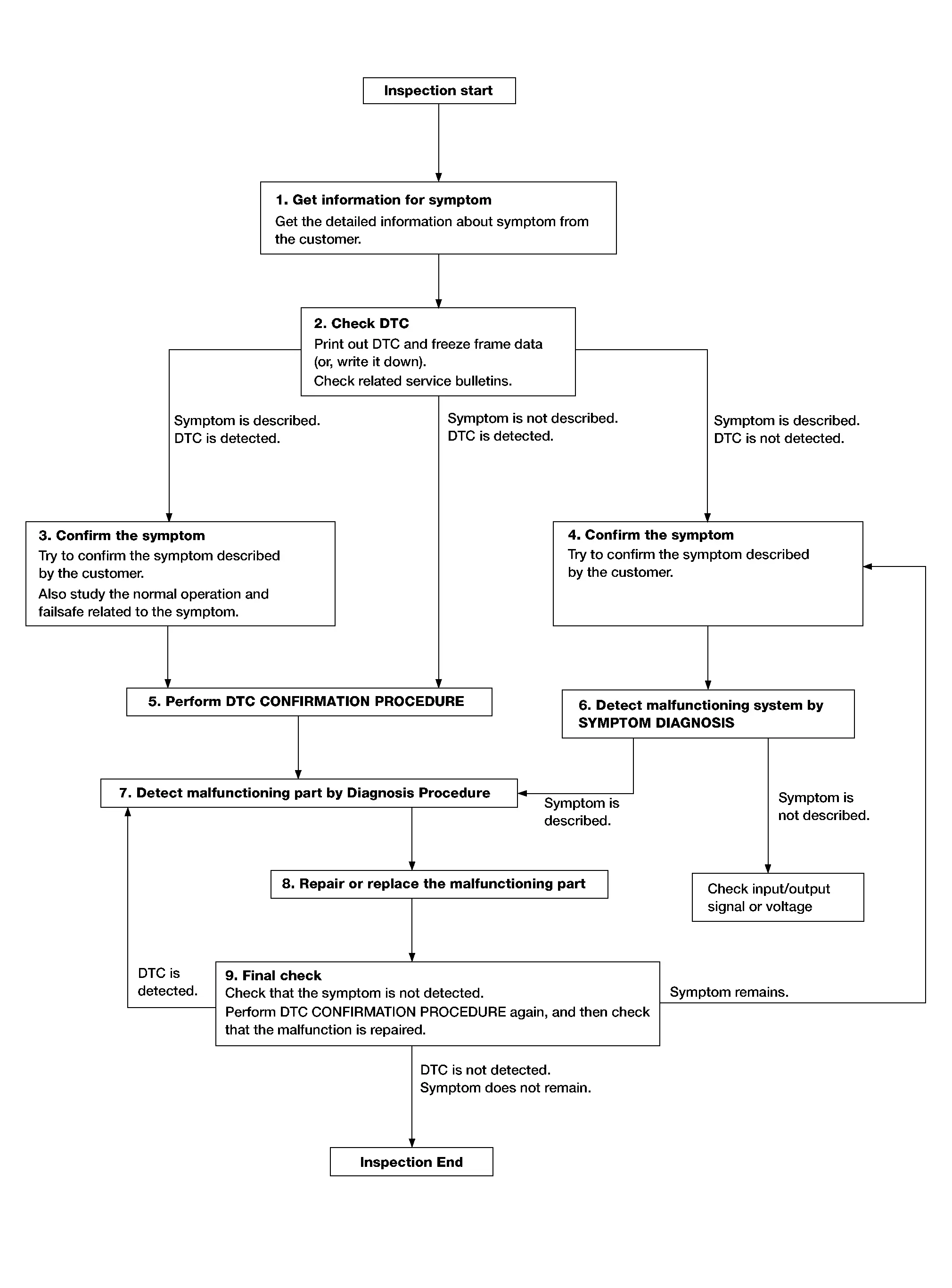

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

GET INFORMATION FOR SYMPTOM

-

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurs).

-

Check operation condition of the function that is malfunctioning.

>>

GO TO 2.

CHECK DTC

-

Check DTC.

-

Perform the following procedure if DTC is detected:

-

Record DTC and freeze frame data (print them).

-

Erase DTC.

-

Study the relationship between the cause detected by DTC and the symptom described by the customer.

-

-

Check related service bulletins for information.

Are any symptoms described and any DTC detected?

Symptom is described, DTC is detected>>GO TO 3.

Symptom is described, DTC is not detected>>GO TO 4.

Symptom is not described, DTC is detected>>GO TO 5.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Also study the normal operation and fail-safe related to the symptom.

Verify relation between the symptom and the condition when the symptom is detected.

>>

GO TO 5.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Verify relation between the symptom and the condition when the symptom is detected.

>>

GO TO 6.

PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC CONFIRMATION PROCEDURE for the detected DTC, and then check that DTC is detected again. At this time, always connect CONSULT to the Nissan Pathfinder vehicle, and check self diagnostic results in real time.

If two or more DTCs are detected, refer to DTC INSPECTION PRIORITY CHART, and determine trouble diagnosis order.

NOTE:

NOTE:

-

Freeze frame data is useful if the DTC is not detected.

-

Perform Component Function Check if DTC CONFIRMATION PROCEDURE is not included on Service Manual. This simplified check procedure is an effective alternative though DTC cannot be detected during this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC CONFIRMATION PROCEDURE.

Is DTC detected?

YES>>GO TO 7.

NO>>Check according to Intermittent Incident.

DETECT MALFUNCTIONING SYSTEM BY SYMPTOM DIAGNOSIS

Detect malfunctioning system according to SYMPTOM DIAGNOSIS based on the confirmed symptom in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

Is the symptom described?

YES>>GO TO 7.

NO>>Monitor input data from related sensors or check voltage of related module terminals using CONSULT.

DETECT MALFUNCTIONING PART BY DIAGNOSIS PROCEDURE

Inspect according to Diagnosis Procedure of the system.

Is malfunctioning part detected?

YES>>GO TO 8.

NO>>Check according to Intermittent Incident.

REPAIR OR REPLACE THE MALFUNCTIONING PART

-

Repair or replace the malfunctioning part.

-

Reconnect parts or connectors disconnected during Diagnosis Procedure again after repair and replacement.

-

Check DTC. If DTC is detected, erase it.

>>

GO TO 9.

FINAL CHECK

When DTC is detected in step 2, perform DTC CONFIRMATION PROCEDURE again, and then check that the malfunction is repaired securely.

When symptom is described by the customer, refer to confirmed symptom in step 3 or 4, and check that the symptom is not detected.

Is DTC detected and does symptom remain?

YES>>DTC is detected: GO TO 7.

YES>>Symptom remains: GO TO 4.

NO>>Before returning the Nissan Pathfinder vehicle to the customer, always erase DTC.

Operation Inspection Nissan Pathfinder

Automatic Air Conditioning System

Work Procedure

DESCRIPTION

The purpose of the operation inspection is to check that the individual system operates normally.

| Check condition | : Engine running at normal operating temperature. |

OPERATION INSPECTION

CHECK MEMORY FUNCTION

-

Press AUTO switch to activate air conditioning.

-

Set temperature to 89°F (32.0°C) by operating temperature control dial (driver side).

-

Press ON·OFF switch.

-

Ignition switch OFF.

-

Ignition switch ON.

-

Press AUTO switch.

-

Check that the set temperature 89°F (32.0°C) is maintained.

Is the inspection result normal?

YES>>GO TO 2.

NO>>GO TO 11.

CHECK FAN SPEED

-

Start engine.

-

Operate fan switch and check that fan speed changes.

-

Check operation for all fan speeds.

Is the inspection result normal?

YES>>GO TO 3.

NO>>GO TO 11.

CHECK AIR OUTLET

-

Operate fan switch to set the fan speed to maximum speed.

-

Operate MODE switch and DEF switch.

-

Check that air outlets change according to each indicated air outlet by placing a hand in front of the outlets.

Is the inspection result normal?

YES>>With rear air control: GO TO 4.

YES>>Without rear air control: GO TO 5.

NO>>GO TO 11.

CHECK AIR INLET (WITH REAR AIR CONTROL)

-

Press REC switch to set the air inlet to recirculation. The REC switch indicator turns ON.

-

Listen to intake sound and confirm air inlets change.

-

Press FRE switch again to set the air inlet to fresh air intake. The FRE switch indicator turns ON.

-

Listen to intake sound and confirm air inlets change.

Is the inspection result normal?

YES>>GO TO 6.

NO>>GO TO 11.

CHECK AIR INLET (WITHOUT REAR AIR CONTROL)

-

Press intake switch to set the air inlet to recirculation. The intake switch indicator turns ON.

-

Listen to intake sound and confirm air inlets change.

-

Press intake switch again to set the air inlet to fresh air intake. The intake switch indicator turns OFF.

-

Listen to intake sound and confirm air inlets change.

Is the inspection result normal?

YES>>GO TO 6.

NO>>GO TO 11.

CHECK A/C COMPRESSOR

-

Press A/C switch. The A/C switch indicator turns ON.

-

Check visually and by sound that the A/C compressor operates.

-

Press A/C switch again. The A/C switch indicator turns OFF.

-

Check that A/C compressor stops.

Is the inspection result normal?

YES>>GO TO 7.

NO>>GO TO 11.

CHECK DISCHARGE AIR TEMPERATURE

-

Operate temperature control dial (driver side).

-

Check that discharge air temperature (driver side) changes.

-

Operate temperature control dial (passenger side).

-

Check that discharge air temperature (passenger side) changes.

-

Operate temperature control switch (rear air control).

-

Check that discharge rear air temperature changes.

-

Press SYNC switch. SYNC switch indicator turns ON.

-

Check that air temperature setting [front (driver side/passenger side) / rear] is unified to the driver side temperature setting.

Is the inspection result normal?

YES>>GO TO 8.

NO>>GO TO 11.

CHECK WITH TEMPERATURE SETTING LOWERED

-

Operate A/C compressor.

-

Operate temperature control dial (driver side) to lower the set temperature to "Lo".

-

Check that cool air blows from the air outlets.

Is the inspection result normal?

YES>>GO TO 9.

NO>>GO TO 11.

CHECK TEMPERATURE INCREASE

-

Warm up engine to the normal operating temperature.

-

Operate temperature control dial (driver side) to raise the set temperature to "Hi".

-

Check that warm air blows from the air outlets.

Is the inspection result normal?

YES>>GO TO 10.

NO>>GO TO 11.

CHECK AUTO MODE

-

Press AUTO switch and check that AUTO indicator turns ON.

-

Operate temperature control switch (driver side) to check that fan speed or air outlet changes (the air outlet or fan speed varies depending on the ambient temperature, in-Nissan Pathfinder vehicle temperature, set temperature, and etc.).

Is the inspection result normal?

YES>>Inspection End.

NO>>GO TO 11.

CHECK SELF-DIAGNOSIS

CONSULT

CONSULT

-

Perform self-diagnosis.

-

Check that any DTC is detected.

Is any DTC detected?

YES>>Refer to DTC Index, and perform the appropriate diagnosis.

NO>>GO TO 12.

CHECK FAIL-SAFE ACTIVATION

Check that symptom is applied to the fail-safe activation. Refer to Fail-safe.

>>

Refer to Symptom Table, and perform the appropriate diagnosis.

Additional Service When Replacing Control Unit Nissan Pathfinder 2026

Description

After replaced A/C auto amp., it is necessary to perform control unit configuration with CONSULT. For details, refer to Work Procedure.

AFTER REPLACEMENT

CAUTION:

-

When replacing A/C auto amp. write vehicle specification with CONSULT Nissan Pathfinder vehicle configuration.

-

Never perform vehicle configuration other than performing with new A/C auto amp. or the control function may not operate normally.

Work Procedure

REPLACE A/C AUTO AMP.

Replace A/C auto amp. Refer to Removal and Installation.

>>

GO TO 2.

WRITING Nissan Pathfinder Vehicle SPECIFICATION

Perform configuration (HVAC). Refer to Description.

>>

Work End.

Configuration (hvac) Nissan Pathfinder 2026

Description

Vehicle specification needs to be written with CONSULT because it is not written after replacing the A/C auto amp.

The configuration requires network connection. CONSULT connects to network and then it downloads the configuration data from the server. Then CONSULT writes the Nissan Pathfinder vehicle specification to the A/C auto amp.

Refer to Work Procedure.

NOTE:

NOTE:

For details the network connection and operation, refer to “CONSULT Operation Manual”.

The configuration no need to “save” configuration data from the A/C auto amp. The configuration data is always generated freshly at the server and then downloaded to the CONSULT.

CAUTION:

-

Complete the procedure of “Configuration” in order.

-

If incorrect “Configuration”, incidents might occur.

Work Procedure

WRITING VEHICLE SPECIFICATION

CONSULT

CONSULT

Perform writing Nissan Pathfinder vehicle specification to A/C auto amp. following "Automatic Configuration" procedure of "Configuration" according to CONSULT Operation Manual.

NOTE:

NOTE:

-

Log in the network according to CONSULT guidance.

-

For details the network connection and operation, refer to “CONSULT Operation Manual”.

>>

Work End.

System Setting Nissan Pathfinder

Temperature Setting Trimmer (Front)

DESCRIPTION

If the temperature felt by the customer is different from the air flow temperature controlled by the temperature setting, the A/C auto amp. control temperature can be adjusted to compensate for the temperature setting.

HOW TO SET

CONSULT

CONSULT

Select “TEMP SET CORRECT” in “Work support” mode of “HVAC”.

| Work support items | Display (°C) | Display (°F) |

|---|---|---|

| TEMP SET CORRECT | 3.0 | 6 |

| 2.5 | 5 | |

| 2.0 | 4 | |

| 1.5 | 3 | |

| 1.0 | 2 | |

| 0.5 | 1 | |

| 0 (initial status) | 0 (initial status) | |

| −0.5 | −1 | |

| −1.0 | −2 | |

| −1.5 | −3 | |

| −2.0 | −4 | |

| −2.5 | −5 | |

| −3.0 | −6 |

NOTE:

NOTE:

-

When −6°F (−3.0°C) is corrected on the temperature setting set as 77°F (25.0°C) the temperature controlled by A/C auto amp. is 77°F (25.0°C) −6°F (−3.0°C) = 71°F (22.0°C) and the temperature becomes lower than the temperature setting.

-

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V or less, the setting of the difference between the set temperature and control temperature may be cancelled.

Temperature Setting Trimmer (Rear)

DESCRIPTION

If the temperature felt by the customer is different from the rear air flow temperature controlled by the temperature setting, the A/C auto amp. control temperature can be adjusted to compensate for the temperature setting.

HOW TO SET

CONSULT

CONSULT

Select “TEMP SET CORRECT” in “Work support” mode of “HVAC”.

| Work support items | Display (°C) | Display (°F) |

|---|---|---|

| TEMP SET CORRECT | 3.0 | 6 |

| 2.5 | 5 | |

| 2.0 | 4 | |

| 1.5 | 3 | |

| 1.0 | 2 | |

| 0.5 | 1 | |

| 0 (initial status) | 0 (initial status) | |

| −0.5 | −1 | |

| −1.0 | −2 | |

| −1.5 | −3 | |

| −2.0 | −4 | |

| −2.5 | −5 | |

| −3.0 | −6 |

NOTE:

NOTE:

-

When −6°F (−3.0°C) is corrected on the temperature setting set as 77°F (25.0°C) the temperature controlled by A/C auto amp. is 77°F (25.0°C) −6°F (−3.0°C) = 71°F (22.0°C) and the temperature becomes lower than the temperature setting.

-

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V or less, the setting of the difference between the set temperature and control temperature may be cancelled.

Inlet Port Memory Function (REC)

DESCRIPTION

-

If the ignition switch is placed to the OFF position while the intake switch is set to ON (recirculation), “Perform the memory” or “Do not perform the memory” of intake switch ON (recirculation) condition can be selected.

-

If “Perform the memory” was set, the intake switch will be ON (recirculation) when placing the ignition switch to the ON position again.

-

If “Do not perform the memory” was set, the air inlets will be controlled automatically when placing the ignition switch to the ON position again.

HOW TO SET

CONSULT

CONSULT

Select “REC MEMORY SET” in “Work support” mode of “HVAC”.

| Work support items | Display | Setting |

|---|---|---|

| REC MEMORY SET | WITHOUT (initial status) | Perform the memory of manual REC |

| WITH | Do not perform the memory of manual REC (auto control) |

NOTE:

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V or less, the setting of the REC memory function may be cancelled.

Inlet Port Memory Function (FRE)

DESCRIPTION

-

If the ignition switch is placed to the OFF position while the intake switch is set to OFF (fresh air intake), “Perform the memory” or “Do not perform the memory” of intake switch OFF (fresh air intake) condition can be selected.

-

If “Perform the memory” was set, the intake switch will be OFF (fresh air intake) when placing the ignition switch to the ON position again.

-

If “Do not perform the memory” was set, the air inlets will be controlled automatically when placing the ignition switch to the ON position again.

HOW TO SET

CONSULT

CONSULT

Select “FRE MEMORY SET” in “Work support” mode of “HVAC”.

| Work support items | Display | Setting |

|---|---|---|

| FRE MEMORY SET | WITHOUT | Perform the memory of manual FRE |

| WITH (initial status) | Do not perform the memory of manual FRE (auto control) |

NOTE:

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V or less, the setting of the FRE memory function may be cancelled.

Foot Position Setting Trimmer

DESCRIPTION

In FOOT mode, the air blowing to DEF can change ON/OFF.

HOW TO SET

CONSULT

CONSULT

Select “BLOW SET” in “Work support” mode of “HVAC”.

| Work support items | Display | Defroster door position | |

|---|---|---|---|

| Auto control | Manual control | ||

| BLOW SET | Mode1 | OPEN | CLOSE |

| Mode2 (initial status) | OPEN | OPEN | |

| Mode3 | CLOSE | OPEN | |

| Mode4 | CLOSE | CLOSE | |

NOTE:

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V or less, the setting of the discharge air mix ratio in FOOT mode may be cancelled.

Setting of Target Evaporator Temperature Upper Limiit Value

DESCRIPTION

Setting of upper limit value of target evaporator temperature can be changed. Control characteristic of compressor control (freezing protection control and refrigerant discharge amount control) changes according to change of the setting, and then operation ratio of compressor and refrigerant discharge amount are changed. According to change of the setting, control characteristic focusing on the fuel consumption can be adjusted to control characteristic focusing on the cooling capacity.

HOW TO SET

CONSULT

CONSULT

Select “TARGET EVAPORATOR TEMP UPPER LIMIT SETTING” in “Work support” mode of “HVAC”.

| Work support items | Display | Setting |

|---|---|---|

| TARGET EVAPORATOR TEMP UPPER LIMIT SETTING | Initial setting | Setting 1 |

| Low | Setting 4 | |

| Middle (initial status) | Setting 3 | |

| High | Setting 2 |

| Setting | Target evaporator temperature upper limit value | Evaporator freezing protection control | Refrigerant discharge amount control |

|---|---|---|---|

| Setting 1 | 50°F (10°C) | Minimum operation ratio of compressor | Minimum refrigerant discharge amount |

| Setting 2 | 45°F (7°C) | Operation ratio of compressor increases from setting 1. | Refrigerant discharge amount increases from setting 1. |

| Setting 3 | 41°F (5°C) | Operation ratio of compressor increases from setting 2. | Refrigerant discharge amount increases from setting 2. |

| Setting 4 | 37°F (3°C) | Operation ratio of compressor increases from setting 3. | Refrigerant discharge amount increases from setting 3. |

NOTE:

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V or less, the setting of the target evaporator temperature upper limit setting may be cancelled.

Nissan Pathfinder (R53) 2022-2026 Service Manual

Basic Inspection

- Diagnosis and Repair Work Flow

- Operation Inspection

- Additional Service When Replacing Control Unit

- Configuration (hvac)

- System Setting

Contact Us

Nissan Pathfinder Info Center

Email: info@nipathfinder.com

Phone: +1 (800) 123-4567

Address: 123 Pathfinder Blvd, Nashville, TN 37214, USA

Working Hours: Mon–Fri, 9:00 AM – 5:00 PM (EST)